Hi everyone,

I'm triyng to duplicate and then to improve an old driver for a BLDC motor with DRV8301 kit (F2806x Iso Control Card).

The system must work with a battery power supply (range 50.4V full charge to 33.4V low limit charge).

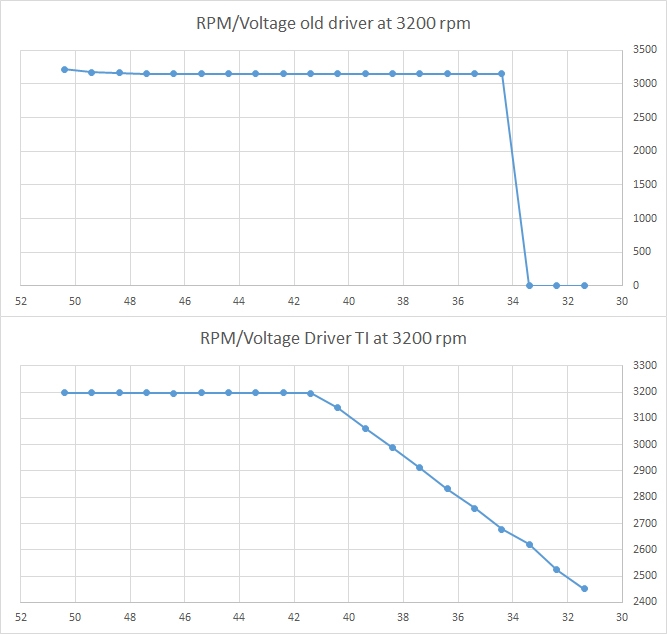

Decreasing on-line the power supply voltage to simulate the battery behavior, I found two different graph shown in photo (No load motor):

The good news is that the TI driver continues to work under 34V and in the power on from 0 speed (motor stopped) the TI driver always starts the motor in contrast to the old driver that under 40V in unable to start the motor.

The bad news is that, if the motor runs at 3200 rpm and the power supply voltage decreases, under 41V the speed decreases drastically.

I know that decreasing Vbus will always decrease the max speed but I see that the old driver absorbs gradually more current during the decreasing of power supply voltage to have almost the same power and to perform the target speed.

There is a way to perform the same thing also in the TI driver?

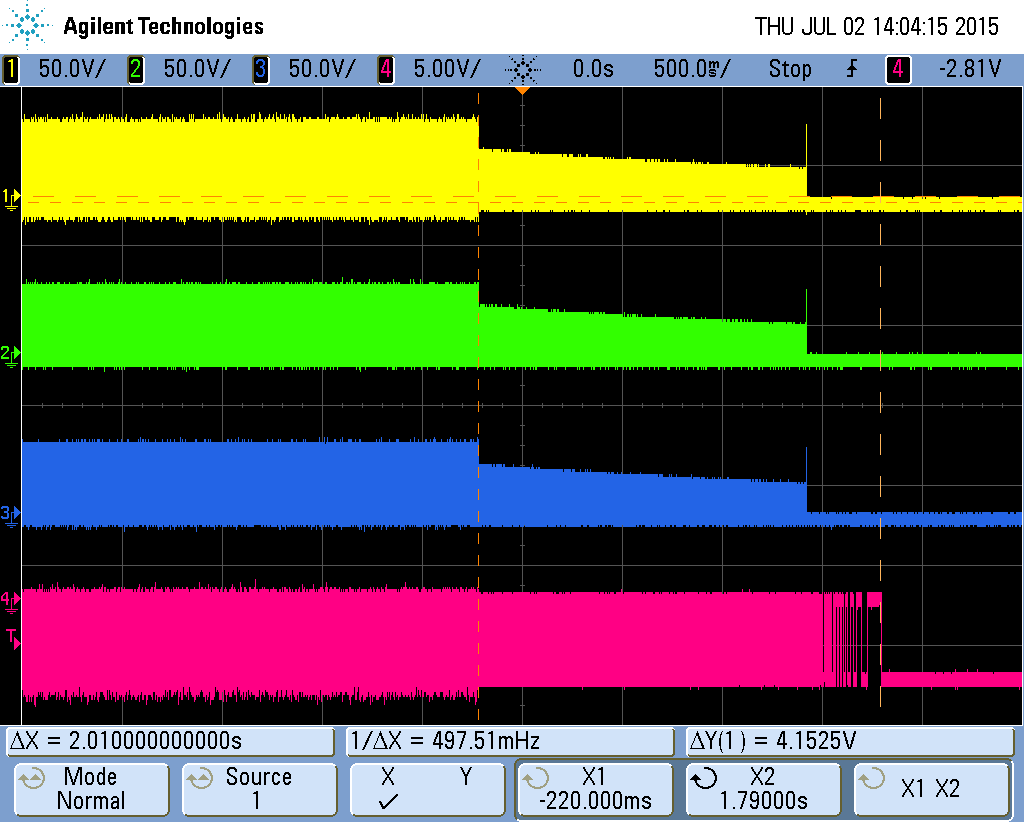

I also must stop the motor as quick as possible (under 3 seconds with all kind of load for safety conditions); now I'm using the HAL_disablePwm(halHandle) to stop the motor, there is another way more fast and safe?

Thanks in advice and sorry for my bad english,

Matteo