hello,

the error is when i enable the gMotorVars.Flag_enablesys & gMotorVars.Flag_Run_Identify, motor reach max speed suddenly(very fast).

and change SpeedRef_krpm value is no effect.

and it did not happend every time,

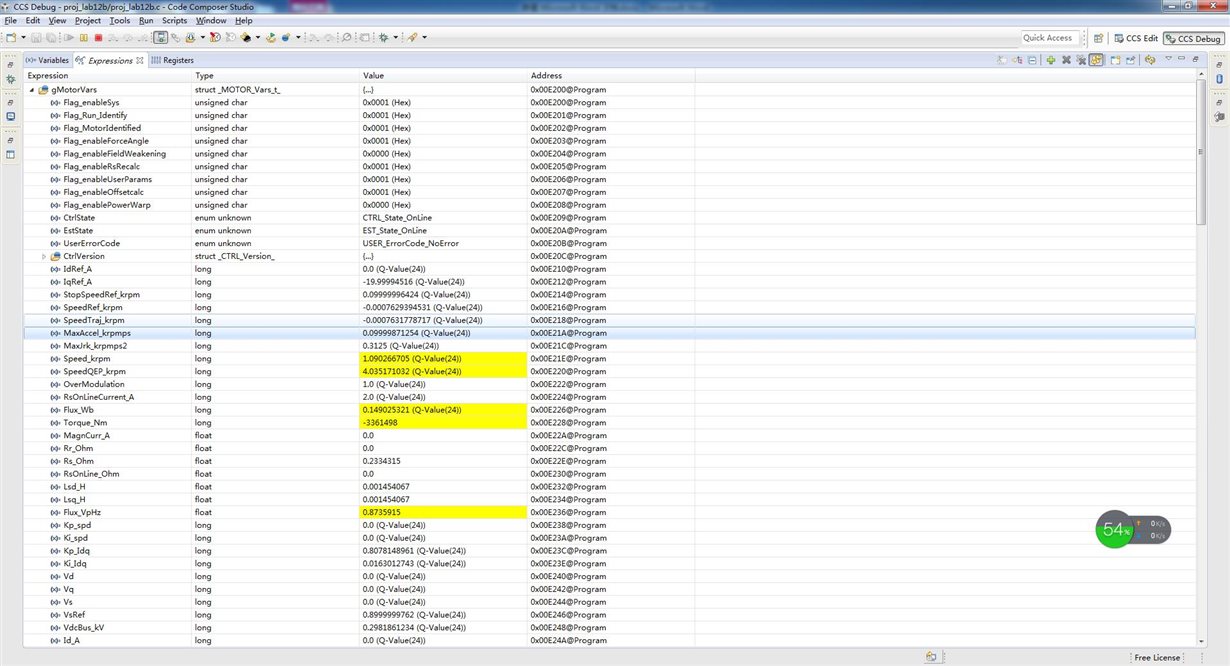

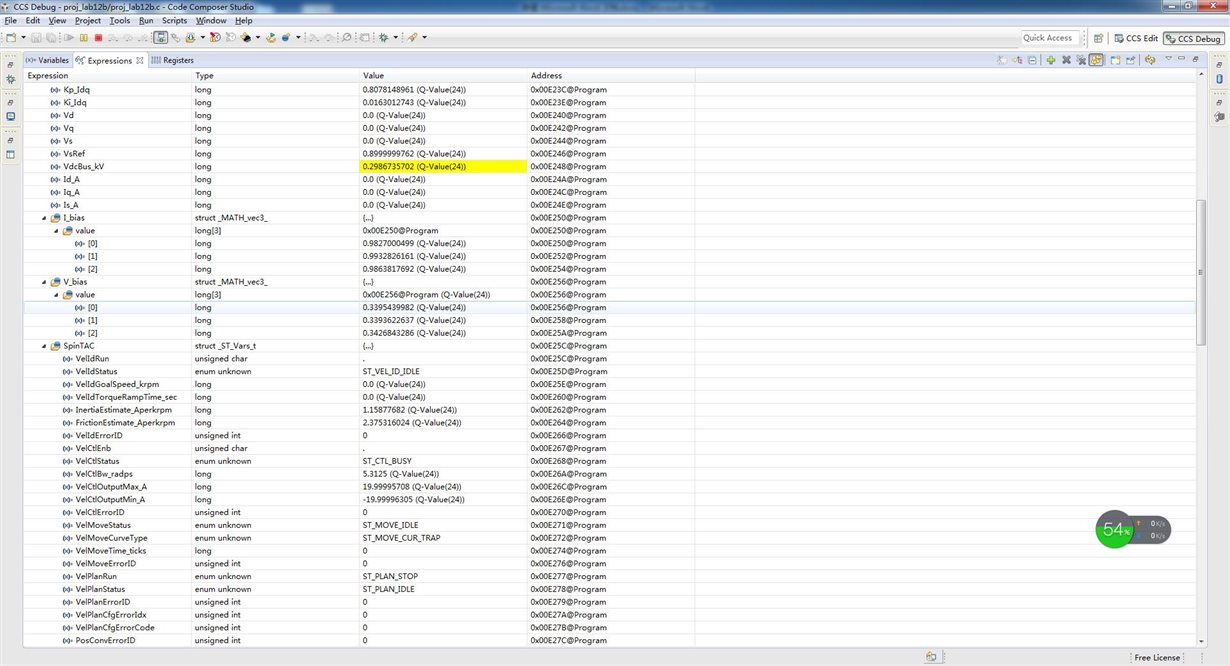

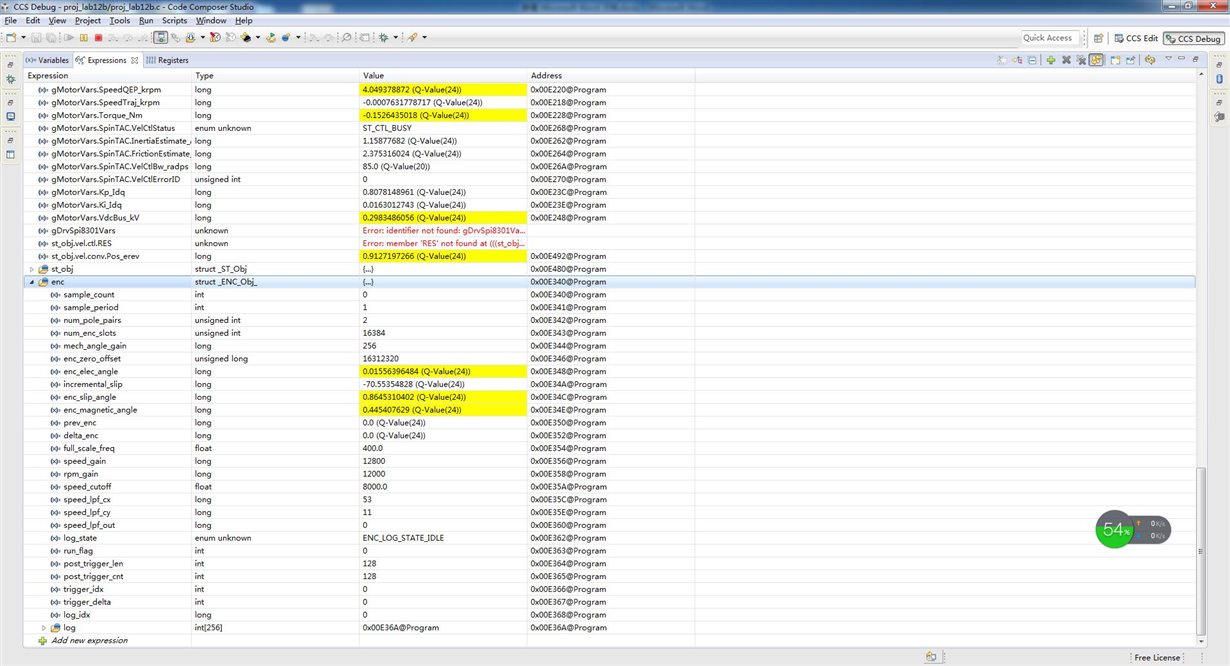

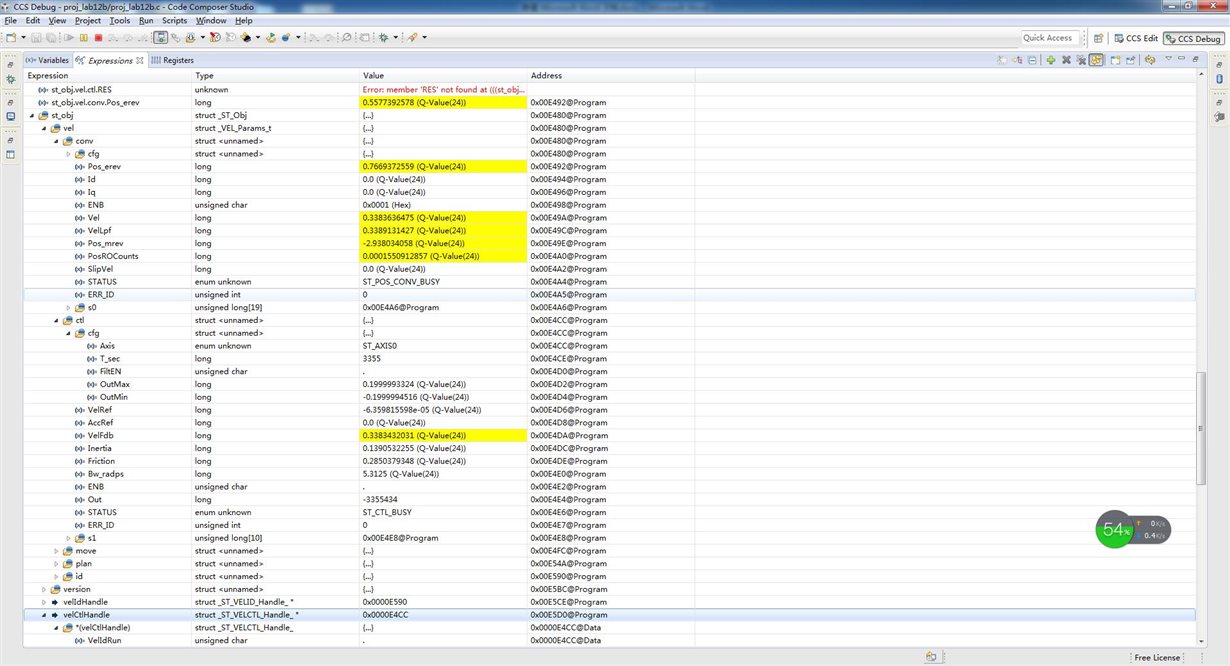

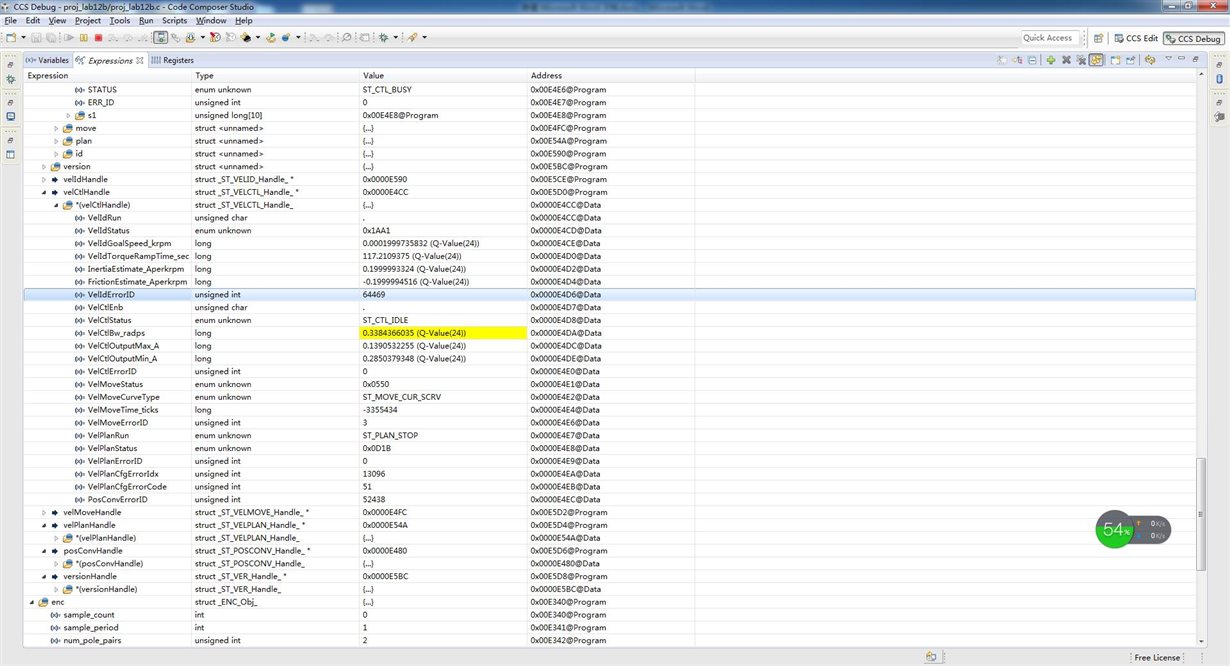

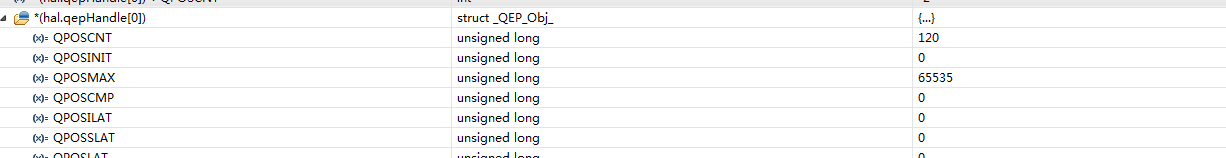

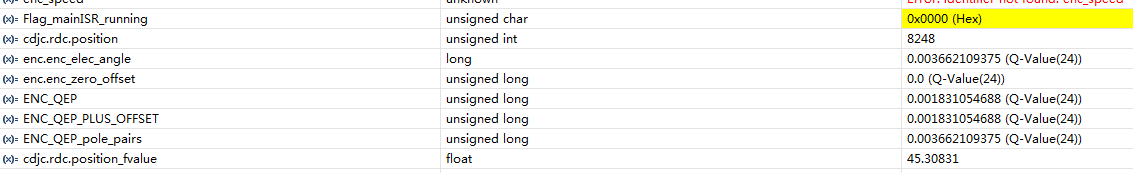

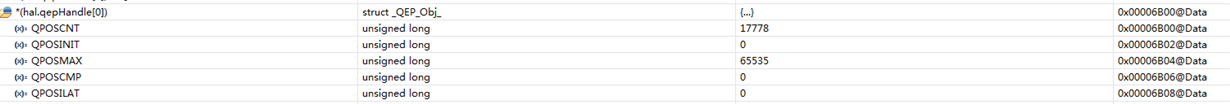

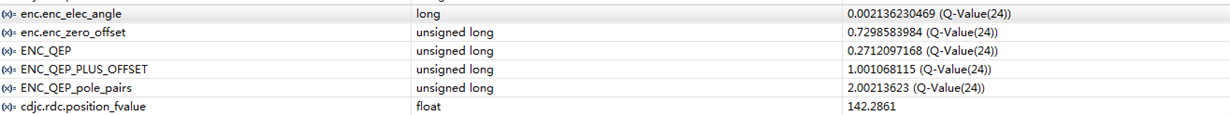

this is the screenshot when error happend with lab12b.