Hi,

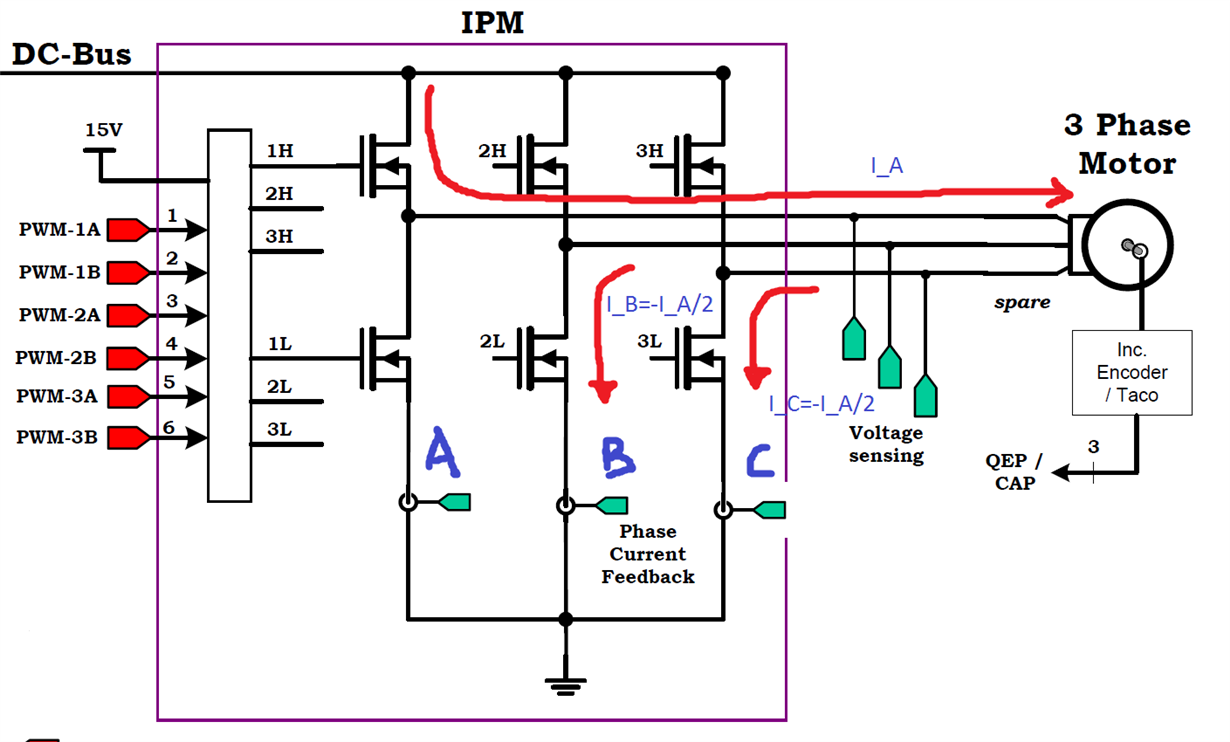

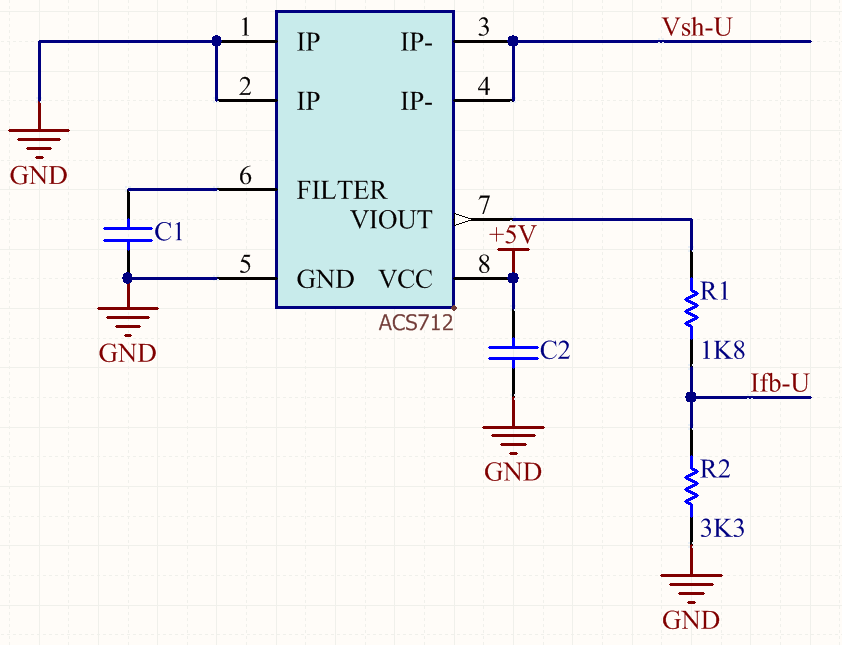

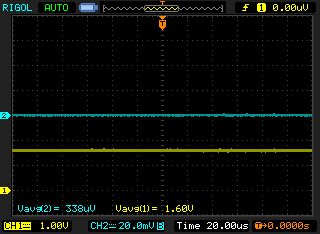

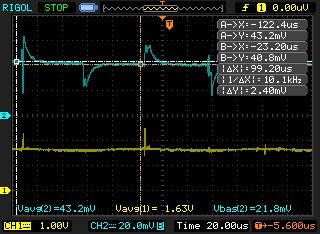

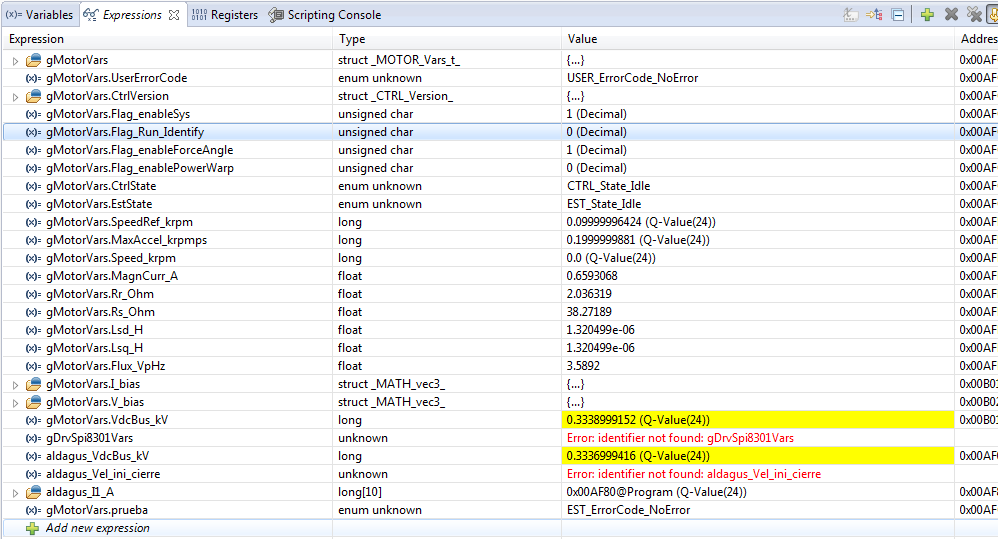

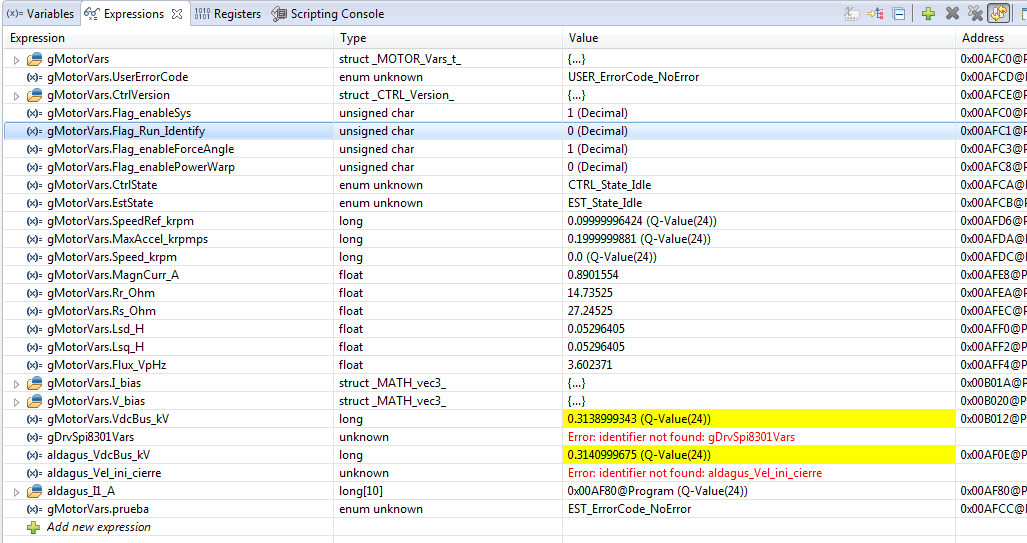

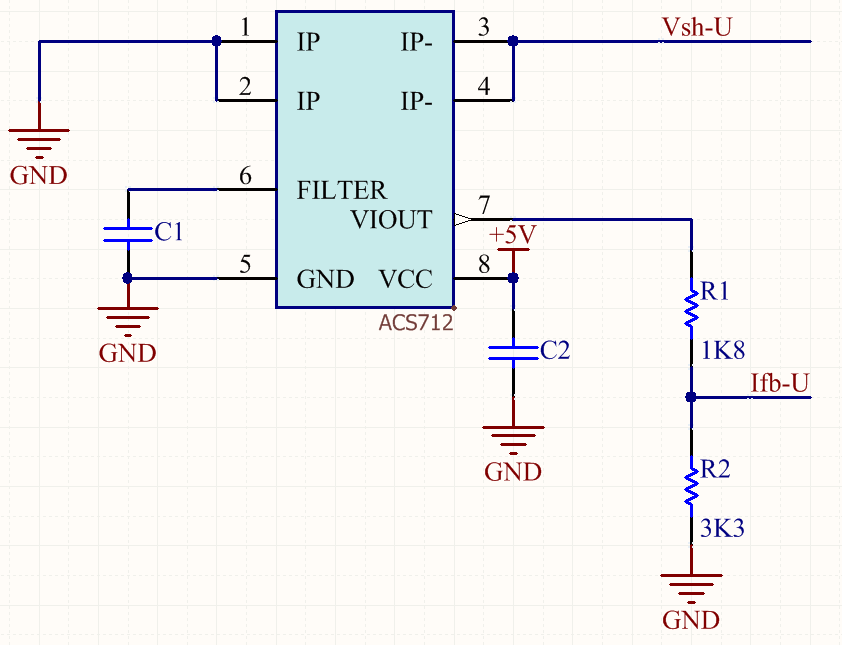

I built my own hardware very similar to the HVkit board. I´m using a LaunchXL F28069M as the main processor. I have something wrong with my current sense circuits. My shunt resistor are OK (or I think so). I chose the same HV Kit´s opamp and the same feedback resistors.When I put the same HV Kit´s values of USER_IQ_FULL_SCALE_CURRENT_A and USER_ADC_FULL_SCALE_CURRENT_A (as it should be as it´s the same circuit) and tried to identify the motor with the lab2B, the real DC current is much lower than the specified in USER_MOTOR_RES_EST_CURRENT.