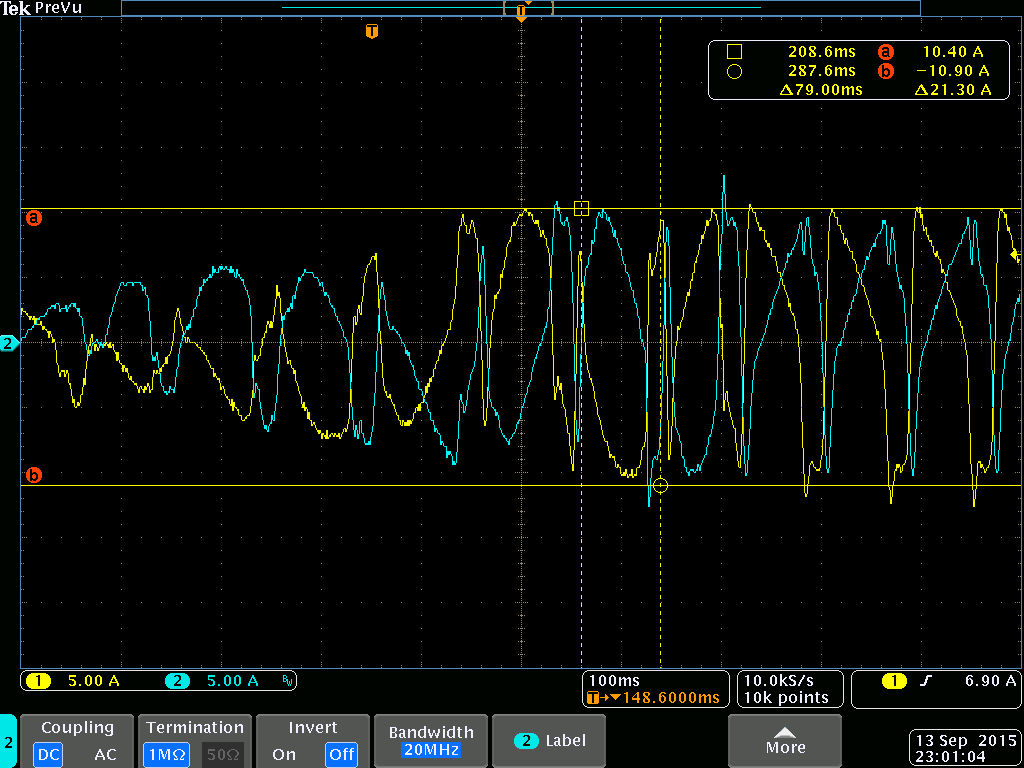

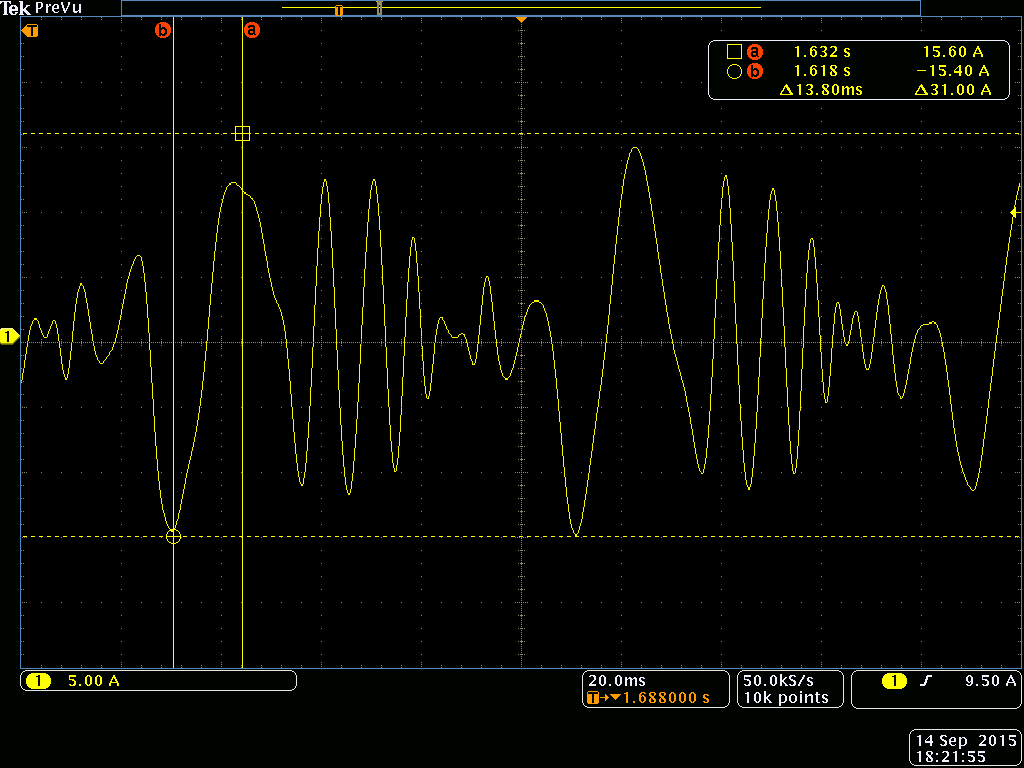

I am working through lab 5b and trying to tune the motor.I am having two issues with the motor starting up. First, I observe that there is a delay for several seconds before the motor ramps up to speed. Sometimes the lag time is too long and the motor does not start up. It appears to ramp up and down erratically for several seconds. I can see the driver providing a very odd shaped current to the motor. I turn everything off when the motor gets about 10 deg C below max operating temperature. I have a couple of questions in general concerning the labs. In lab 4, should the motor be connected to its load? Without a load, the motor ramps up fine with a Iqref of approximately 1 A and spins at 1 Krpm. With a load I can't get it to turn even at 3.3 amps, which I would expect due to the extra inertia of the load. It looks like I need more current at start up than the motor drive is providing. Do I need to adjust the current magnitude for the force angle?

Thanks,

Chuck