Dear My Friends:

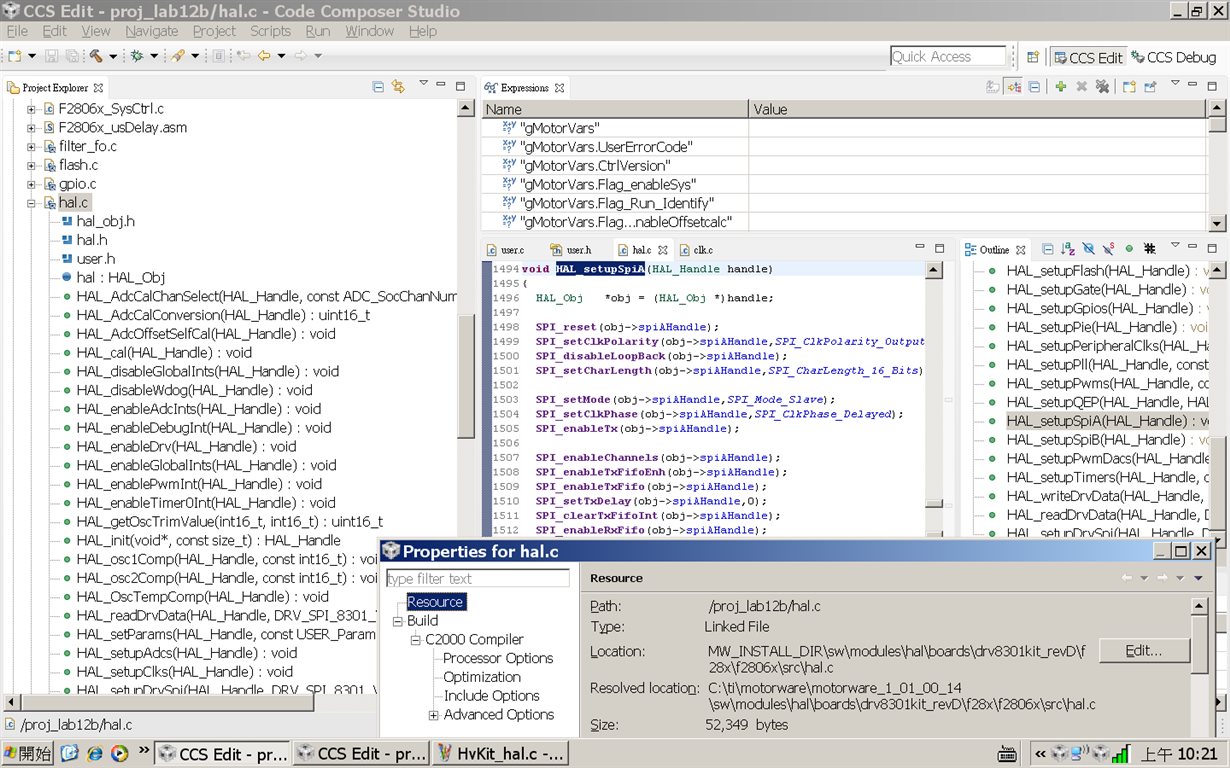

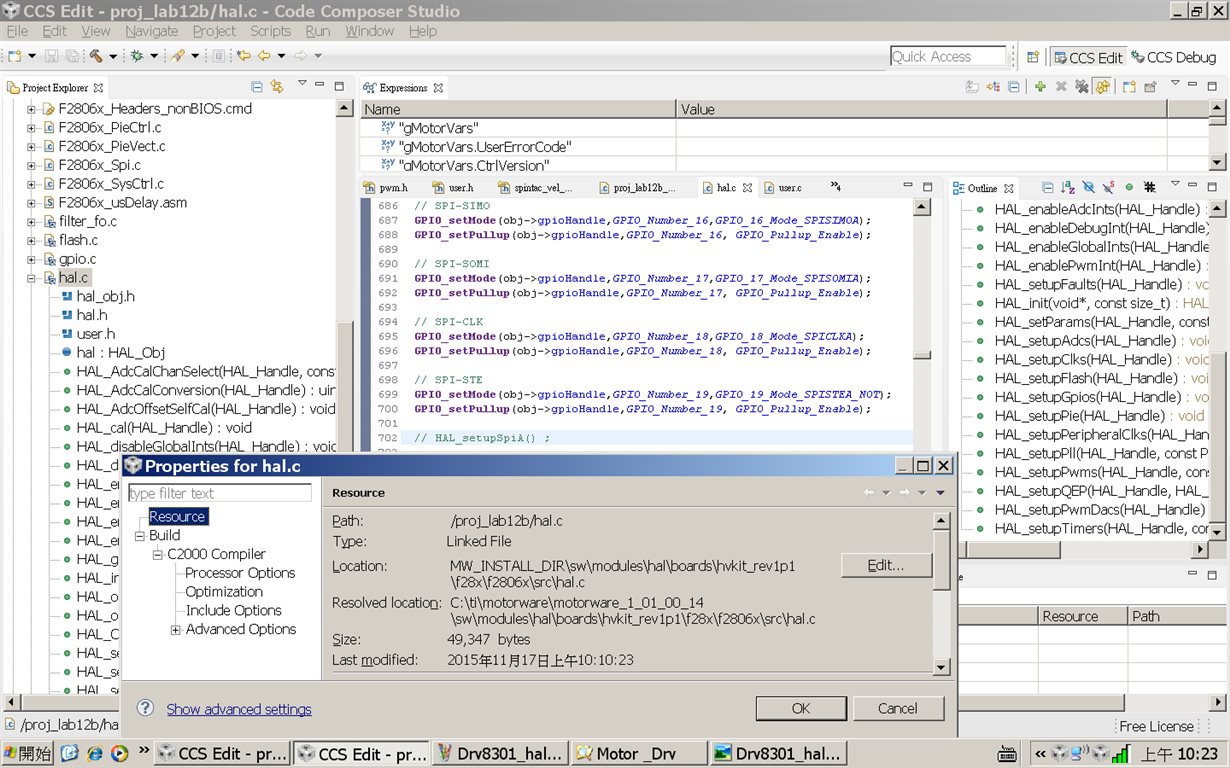

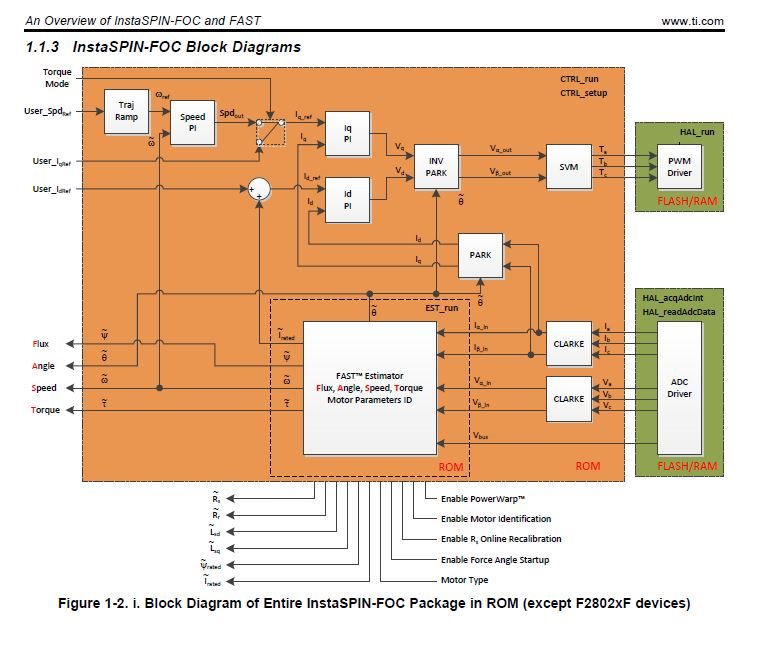

I have a PMSM , resolver kit and Hv-kit with F28069 controller and I hope to use SPI(slave) to get PMSM postion from resolver Kit(master).I found that there is a SPI-A interface in H2 connector in pin1,3,5 and 7 in the Hv-Kit.I am trying to add SPI(slave) firmware in F28069 of Hv-kit to read rotation postion of PMSM from TI-resolver Kit.Is it possible to implement the function of reading resolver data by SPI ?

Best Regards,

Sheng-Hua