While doing the labs I have noticed the problem that my power supply is only showing 3A of current usage, while I set my USER_IQ_FULL_SCALE_CURRENT_A to 24 and USER_ADC_FULL_SCALE_CURRENT_A to 47.14. If I try to go any higher, I get current too high errors which is obvious. I am using the LAUNCHXL-F28069M board with the DRV8305 Booster. These are my motor parameters:

#define USER_MOTOR_TYPE MOTOR_Type_Pm #define USER_MOTOR_NUM_POLE_PAIRS (20) #define USER_MOTOR_Rr (NULL) #define USER_MOTOR_Rs (0.0484125465) #define USER_MOTOR_Ls_d (3.53583055e-05) #define USER_MOTOR_Ls_q (3.53583055e-05) #define USER_MOTOR_RATED_FLUX (0.0241114106) #define USER_MOTOR_MAGNETIZING_CURRENT (NULL) #define USER_MOTOR_RES_EST_CURRENT (3.0) #define USER_MOTOR_IND_EST_CURRENT (-3.0) #define USER_MOTOR_MAX_CURRENT (24.00) #define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0) #define USER_MOTOR_ENCODER_LINES (1024.0) #define USER_MOTOR_MAX_SPEED_KRPM (1.920) #define USER_SYSTEM_INERTIA (0.2552739978) #define USER_SYSTEM_FRICTION (0.7534176111) #define USER_SYSTEM_BANDWIDTH_SCALE (1.0)

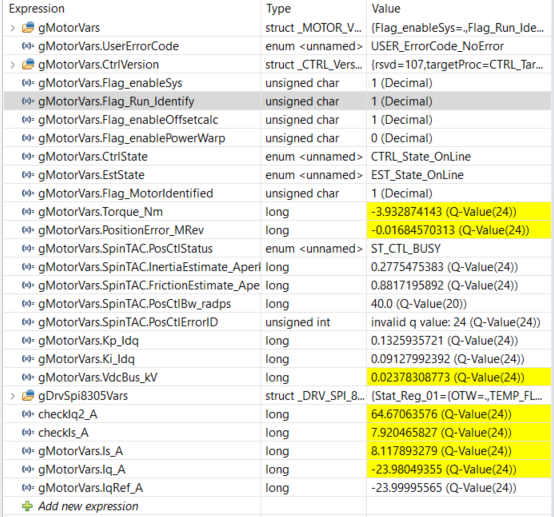

As you can see I've already went and done most of the labs, the motor is correctly Identified, I can do position control with an incremental encoder with lab13a. I would like to start pushing more current through the motor. This is probably a [PU] vs [A] kind of problem, because when I observe IqRef_A during debugging, it actually goes all the way to 23.9999, but the power supply (which is capable of doing 10A@24V) only shows an output of 3A. What I would like to know is how can I start setting values in actual amps and not PU, or at least convert them in a meaningful way, so that I know what I'm doing. How is this all scaled? Any kind of help is much appreciated.