Current consumption ISSUE

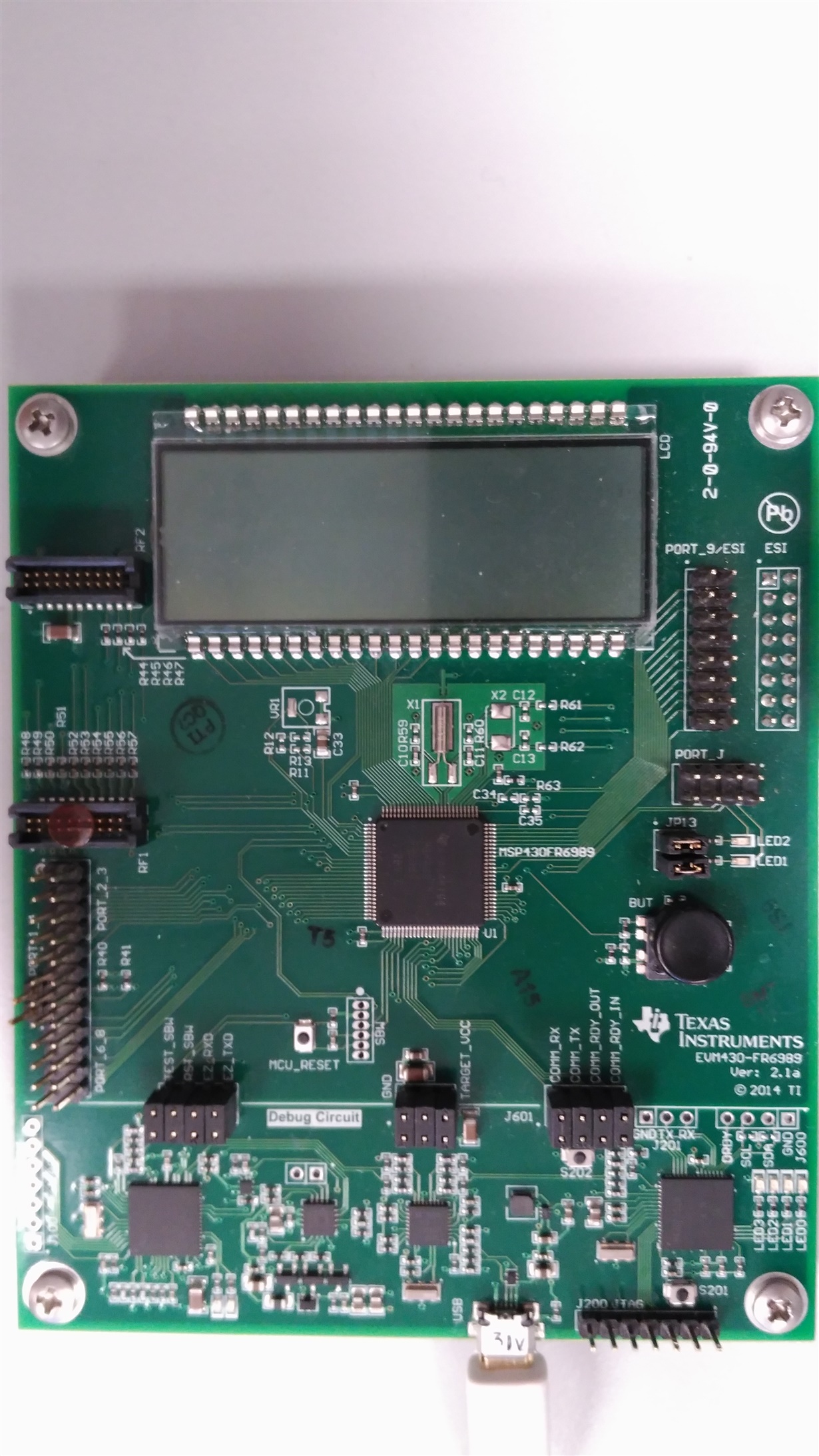

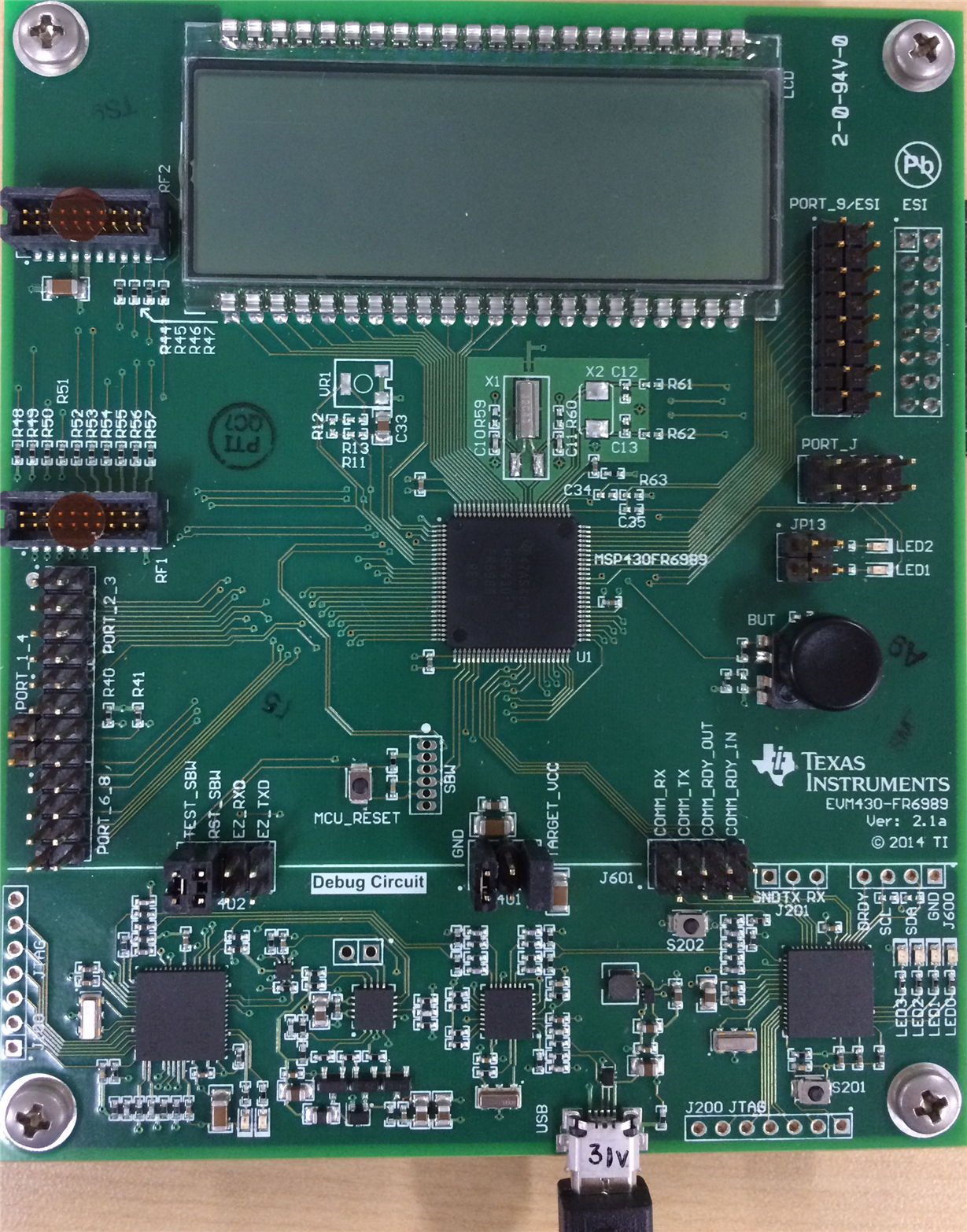

We are working on MSP430FR598X based prototypes and we are having some issues related to current consumption over temperature change.

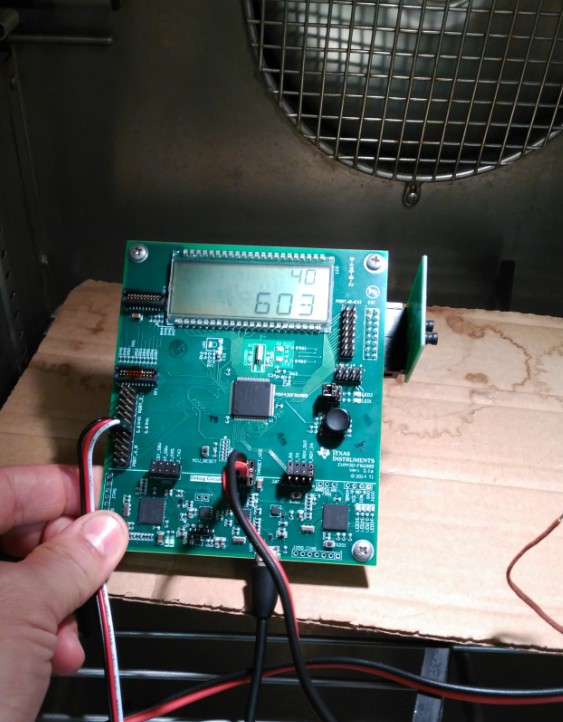

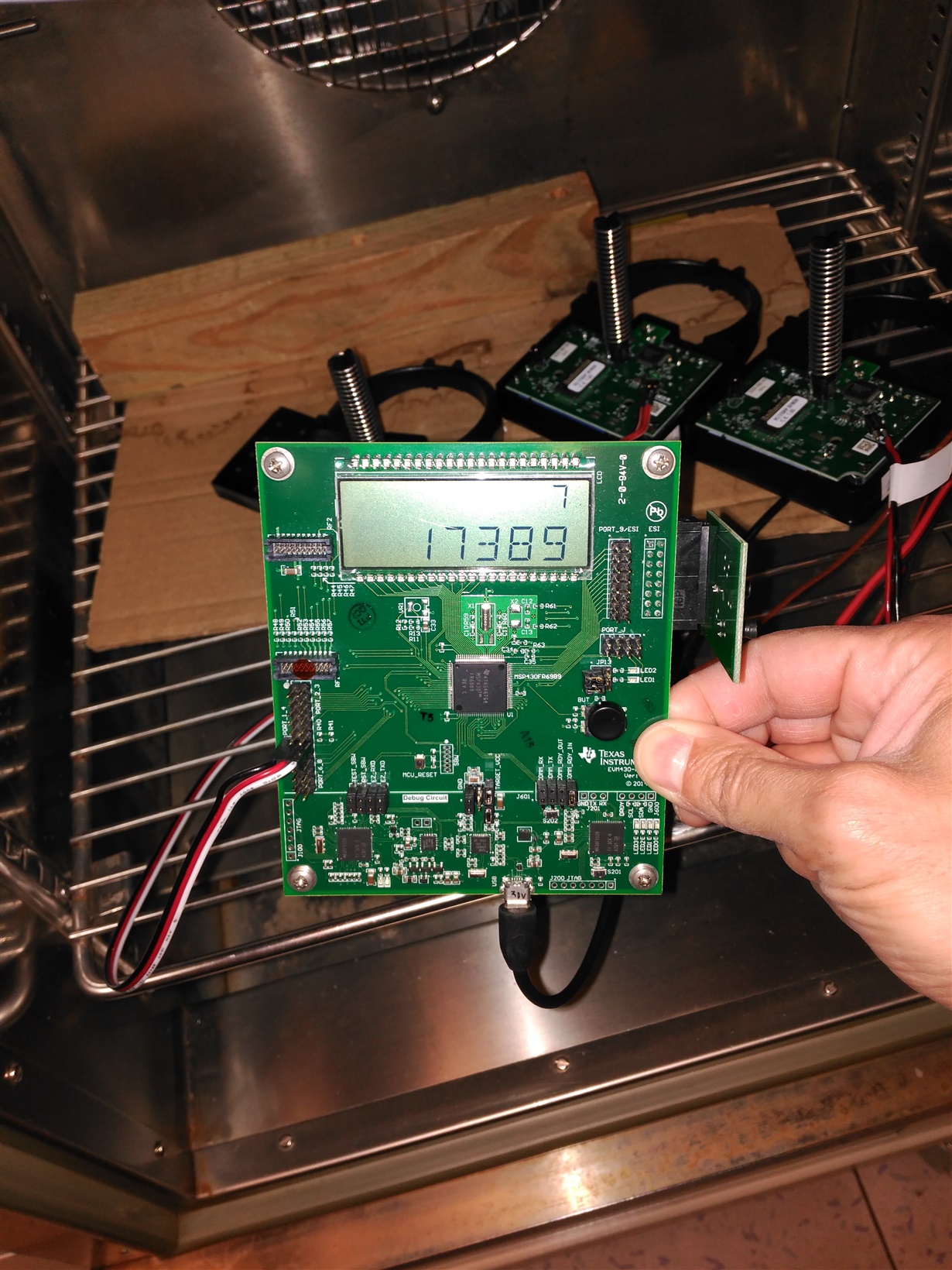

Up to now, we have already developed two different prototypes using both, MSP430FR5989 (Ver 1) and MSP430FR5986 (Ver 2).

Our application is using LC sensing hardware with two external resonant circuits following this AN:

Water Meter Reference Design for two LC Sensors, Using Extended Scan Interface (ESI): http://www.ti.com/tool/TIDM-LC-WATERMTR

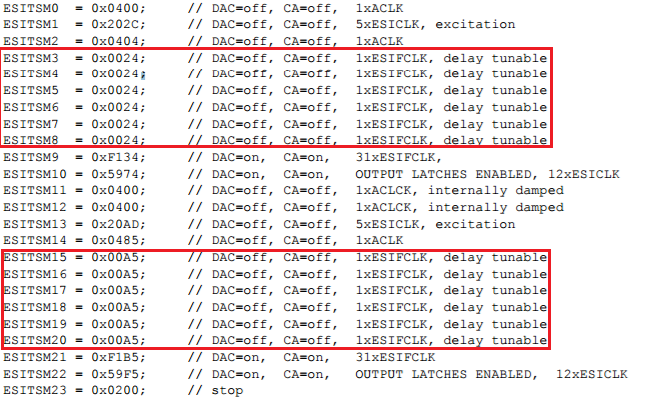

Our FW is using this main routines (ESI_INV_CAL_V1_IIC):

- void InitScanIF(void);

- void ReCalScanIF(void);

- __interrupt void ISR_ESCAN_IF(void)

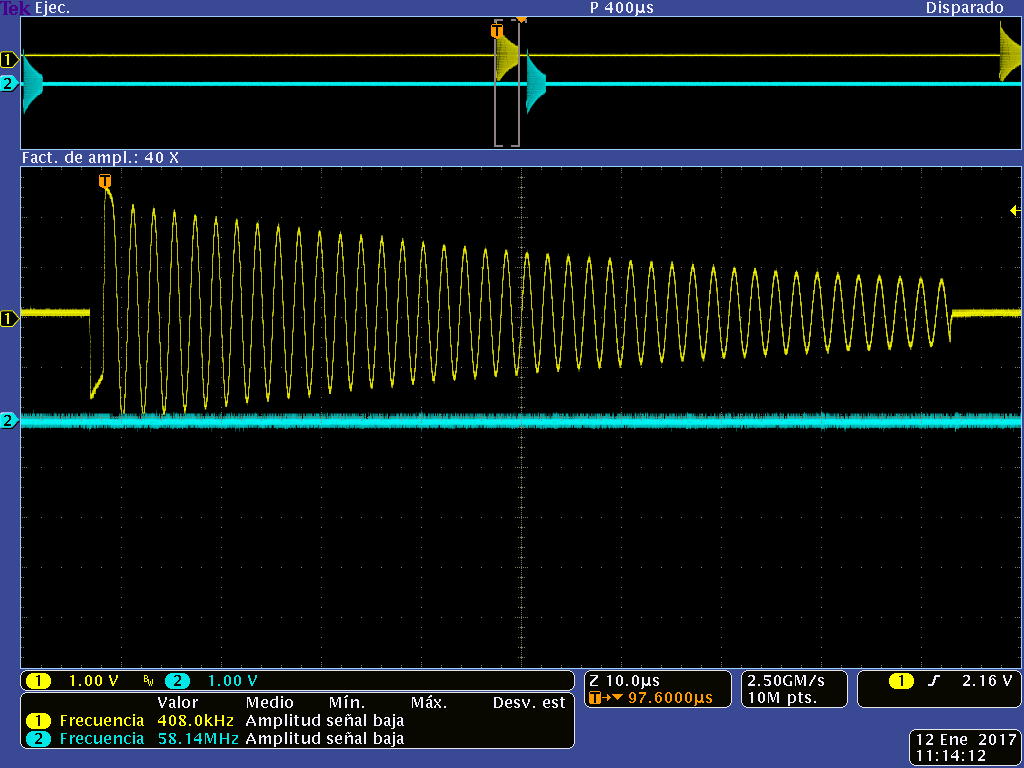

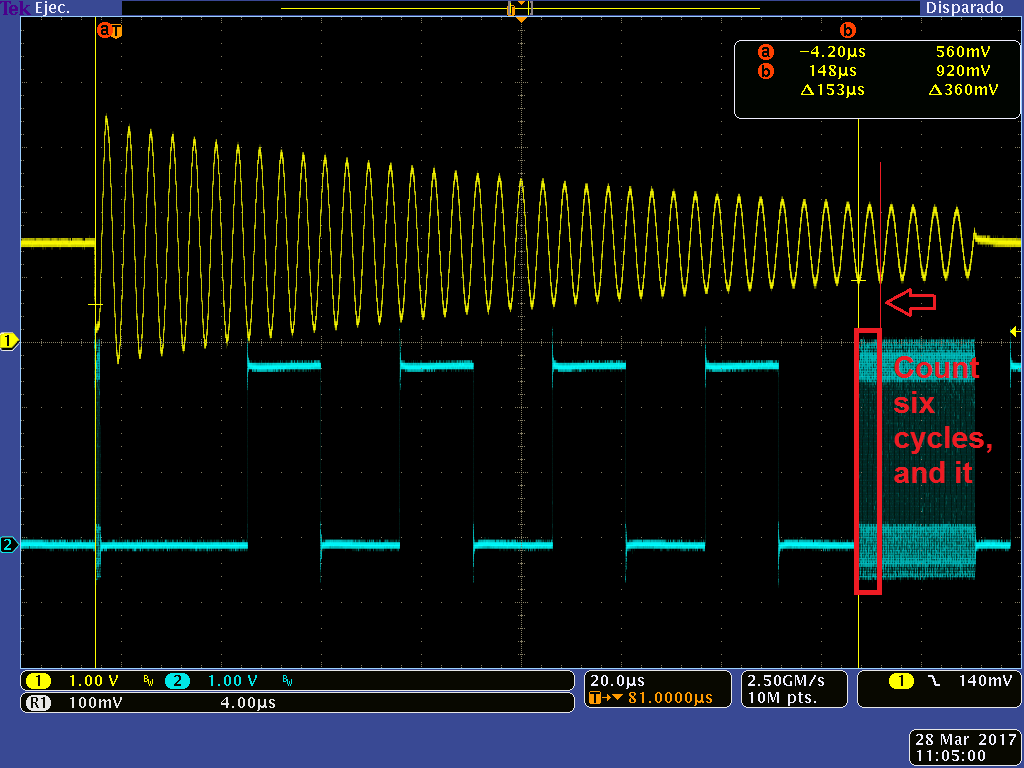

The used resonant circuit is: 2x (1mH + 470pF)

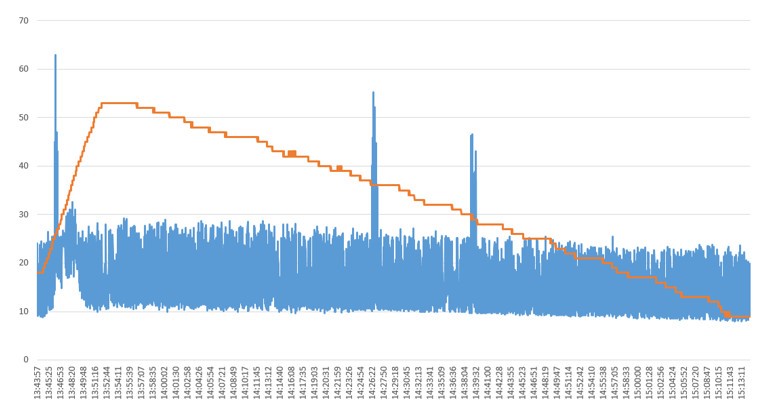

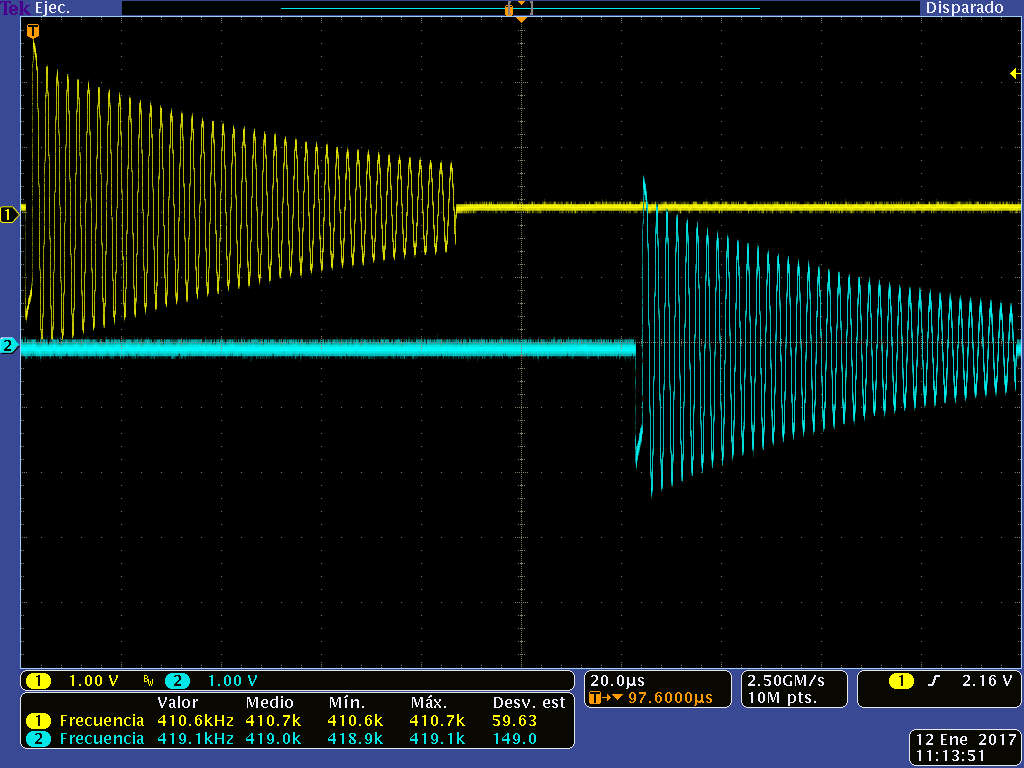

When the FW is running in standby (no metal presence) we have a mean current consumption of about 3.8uA. Approaching metal to LC resonant circuit, excites a state change and MSP raises the current consumption up to about 10-20uA for short time going down again to 4uA.

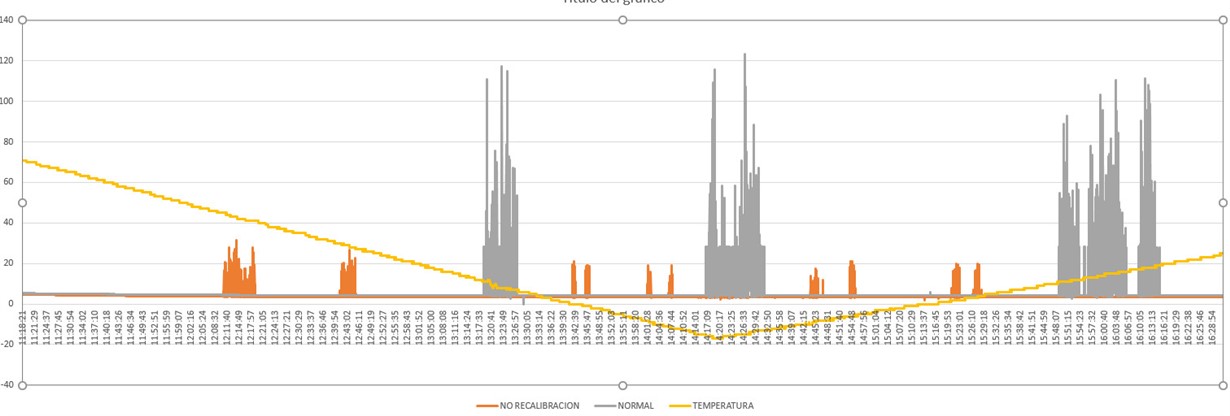

The fact is that we have tested in climatic chamber over the temperature range (+70ºC to -20ºC) and we have detected that MSP current is not stable at 4uA. We have registered the current consumption of 2 boards over temperature (one with recalibration routine active and other without) and there are current peaks without having any kind of reason.

We also have tested in sleep mode (no LC sensing) and the current stays stable at 4uA.

Knowing that, we have we have recorded a video where we have heated coils, capacitors and MSP (around LC sensing HW pins) and we have noticed that heating coils or capacitors has no effect and heating MSP current consumption rises.

Have TI noticed this effect?

We have repeated this test with several prototypes from both versions and we have no pattern about when and how it is generated this effect.

We have plenty of tests done with current consumption records if needed.

Many thanks for your help!

Ruben