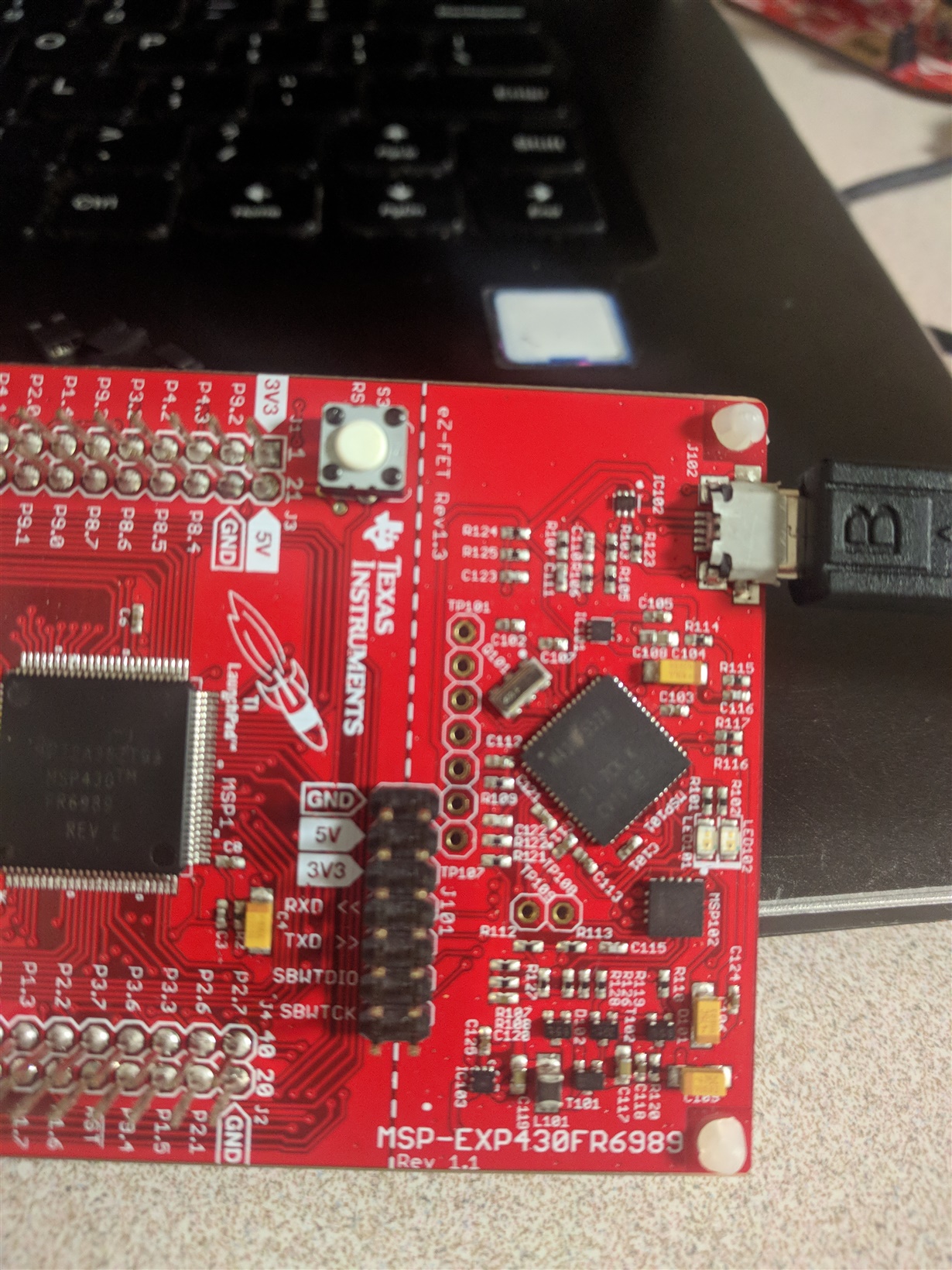

Other Parts Discussed in Thread: ENERGIA, , BOOSTXL-EDUMKII

Tool/software: Code Composer Studio

Hi I am trying to replicate the same scenario as in the previous question. However, as I don't have access to a 10k resistors, are they really necessary? Will it work if I don't make the 10k connections? And also, which jumpers are "eZ-FET lite jumpers" as talked about in the reply that was marked as resolved?

Thanks in advance,