I'm using the Kentec 7.0" 800x480 K70DWN2-V1-FF display connected to the EK-TM4C123GXL Tiva C Series LaunchPad —formerly EK-LM4F120XL LaunchPad— through the EB-LM4F120-L35 BoosterPack.

I'm working on the libraries supplied in this package http://www.kentecdisplay.com/Downloads/ek-tm4c123gxl-boost-l35_131216.rar. The Kentec 7.0" 800x480 K70DWN2-V1-FF display uses the SSD1963 controller.

Surprisingly, the read pixel function isn't implemented for the SSD1963.

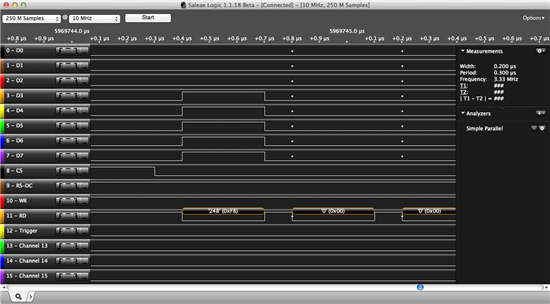

I followed the instruction from the SSD1963 specification sheet but, although the screen sends the correct values 0xf8 0x00 0x00 = red and despite my logic analyser traces them, the port B doesn't read them.

The read pixel works fine for the Kentec 3.5" 320x240 EB-LM4F120-L35 screen, based on the SSD2119.

The major difference between both controllers is: the SSD1963 requires GPIO_STRENGTH_8MA instead of GPIO_STRENGTH_2MA for the SSD2119.

To read from the SSD2119, I'm using

GPIODirModeSet(LCD_DATAH_BASE, LCD_DATAH_PINS, GPIO_DIR_MODE_IN);

Should I add extra parameters to read from the SSD1963

GPIOPadConfigSet(LCD_DATAH_BASE, LCD_DATAH_PINS, GPIO_STRENGTH_8MA, GPIO_PIN_TYPE_STD);

What options should I change?

- Should GPIO_STRENGTH_8MA be changed for a different value?

- Should GPIO_PIN_TYPE_STD be changed for GPIO_PIN_TYPE_STD_WPU?