Hi!

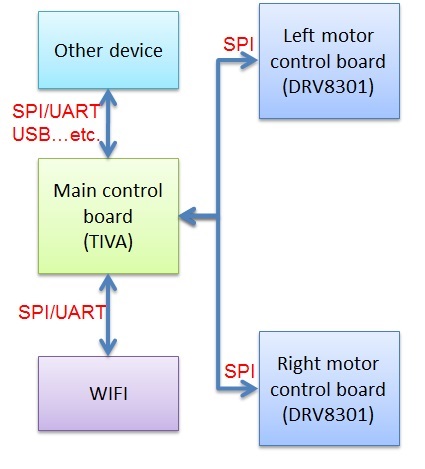

I want to build a balancing robot (like segway). Following is my structure diagram:

The BLDC control kit DRV8301-69M-KIT is considered for both left and right BLDC motor. I want to use the torque control function to drive the robot.

For the tilt angle sensing, I consider the tiva real-time control board(DK-TM4C123G) which has 9-DOF sensor.

My question is can I use tiva to drive both motor control board by SPI communication?

In other words, can the TIVA development board send the control signal to control the torque by motor board, and motor control board also feedback the data of wheel position and velocity?

I haven't used any TI product before, any suggestion will be appreciated.

Thanks!!