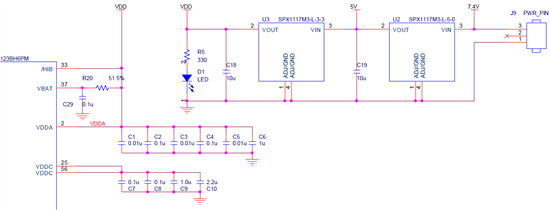

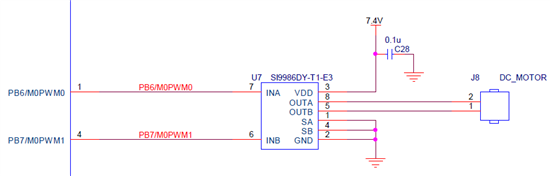

Hi, I'm using TM4C123BH6PM MCU to use a PWM. I'm using this PWM to control my DC motor.

The PWM pulse goes through a motor driver, SI9986.

This is the datasheet of the motor driver.

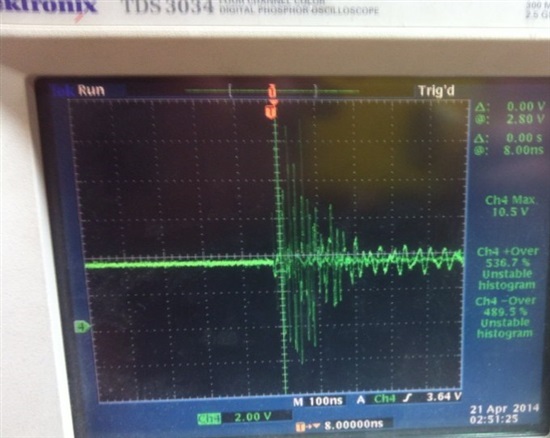

The DC motor works fine when the duty cycle is below 50%. However when the duty goes over 50%,

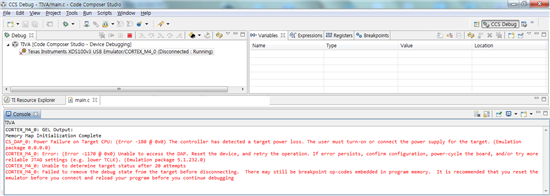

the motor stops and CCS5 gives an error.

Does this error related to GPIO current drive strength?

I configured the GPIO not to be open drain. (GPIOODR = 0)

Also I didn't touch GPIODR2R, GPIODR4R, GPIODR8R, and GPIOSLR.

I'm using CCS5.1, TMS320-XDS100-V3