Hello.

Due to some HW requirements, we had to change from using a 25MHz crystal to a 25MHz external oscillator (which comes from a 50MHz divided by 2) on the OSC0 pin. The SW hasn't changed at all (we were using Tivaware 2.1.0.12573 version).

Is it necessary to change our call to the SysCtlClockFreqSet function? Right now is:

g_ui32SysClock = MAP_SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ | SYSCTL_OSC_MAIN | SYSCTL_USE_PLL | SYSCTL_CFG_VCO_480), 120000000);

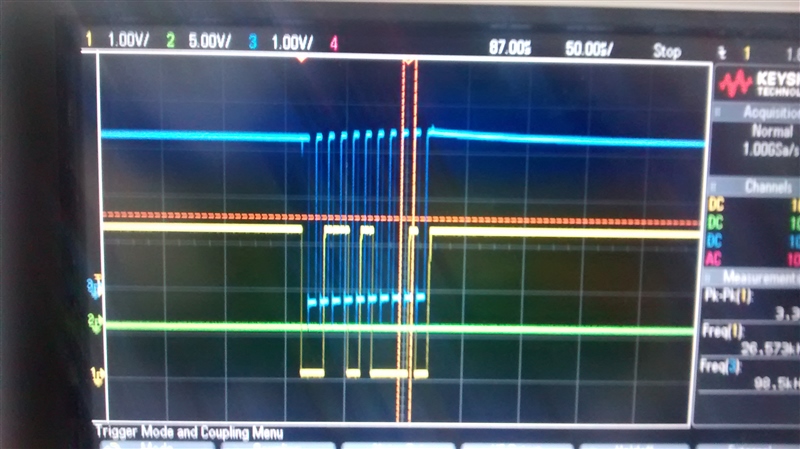

On the other hand, we are seeing some odd behaviour on the I2C ports (SDA and SCL and out of time).

Is there any change in the I2C clocking because of the external oscillator? The I2CMasterInitExpClk call, remains the same.

Thank you