Hello,

I am working with the DRV10983EVM and I am running my small brushless motor. It is starting and running smoothly both in open and closed loop. However, when I apply a sudden force on the rotating shaft it will stop running and lock with a current limit fault. On my oscilloscope I do not see any current spikes at the sudden impact. I apply the impact by just tapping on the rotating shaft, it does not take much force to stop it, just a sudden tap.The lock current limit is set to 3.2A, on my oscilloscope I read a maximum of 0.7A.

Why does the system lock when I only apply such a low current?

I am not 100% certain whether the motor that I am using has a motor electrical constant of above 100us could this cause the problem? And if this causes the problem, which motor driver would you recommend with lower motor electrical constants?

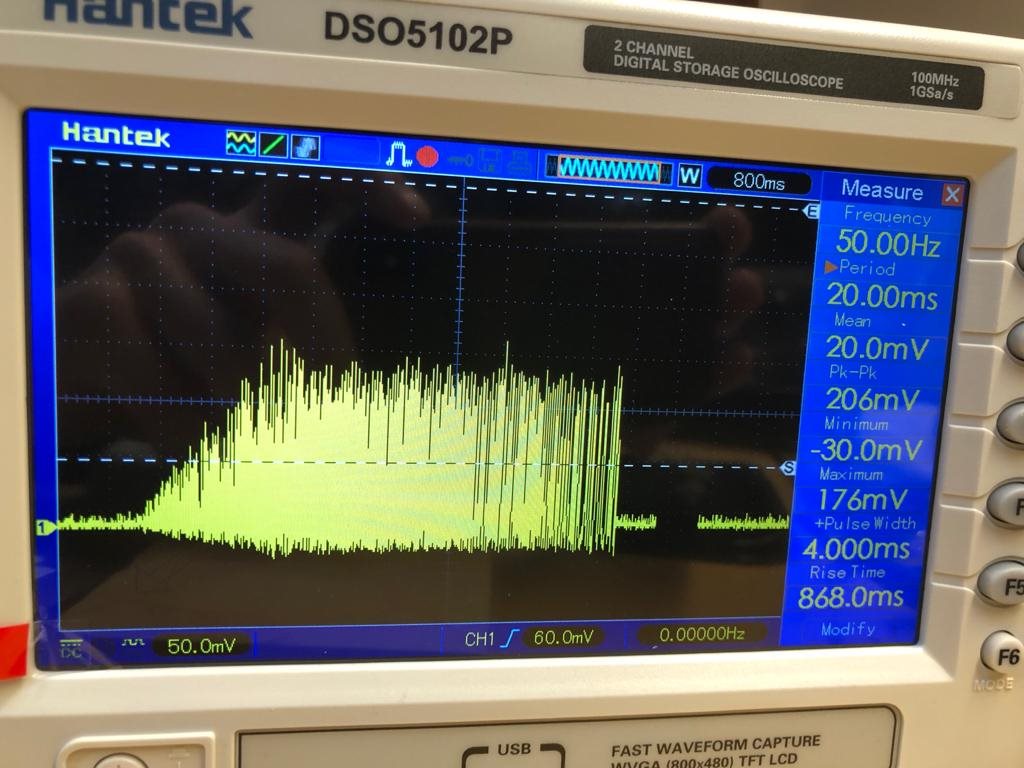

The image below gives the voltage drop over a shunt resistor (0.3Ohm) to indicate the current. First you see the startup behaviour en next I tap the shaft which makes the motor stop with a Lock current limit warning.

Kind regards,

Robin