I have added some custom software in the mainISR in lab 4a to run DRV8323RS stack on top of the 28069M launchpad.

/* --COPYRIGHT--,BSD

* Copyright (c) 2012, Texas Instruments Incorporated

* All rights reserved.

*

* Redistribution and use in source and binary forms, with or without

* modification, are permitted provided that the following conditions

* are met:

*

* * Redistributions of source code must retain the above copyright

* notice, this list of conditions and the following disclaimer.

*

* * Redistributions in binary form must reproduce the above copyright

* notice, this list of conditions and the following disclaimer in the

* documentation and/or other materials provided with the distribution.

*

* * Neither the name of Texas Instruments Incorporated nor the names of

* its contributors may be used to endorse or promote products derived

* from this software without specific prior written permission.

*

* THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS"

* AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO,

* THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

* PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR

* CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

* EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO,

* PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS;

* OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

* WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR

* OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE,

* EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

* --/COPYRIGHT--*/

//! \file solutions/instaspin_foc/src/proj_lab04a.c

//! \brief Using InstaSPIN�FOC only as a torque controller FPU32

//!

//! (C) Copyright 2011, Texas Instruments, Inc.

//! \defgroup PROJ_LAB04A PROJ_LAB04A

//@{

//! \defgroup PROJ_LAB04A_OVERVIEW Project Overview

//!

//! Running InstaSPIN�FOC only as a Torque controller FPU32

//!

// **************************************************************************

// the includes

// system includes

#include <math.h>

#include "main.h"

#ifdef FLASH

#pragma CODE_SECTION(mainISR,"ramfuncs");

#endif

// Include header files used in the main function

// **************************************************************************

// the defines

#define LED_BLINK_FREQ_Hz 5

// **************************************************************************

// the globals

uint_least16_t gCounter_updateGlobals = 0;

bool Flag_Latch_softwareUpdate = true;

CTRL_Handle ctrlHandle;

#ifdef CSM_ENABLE

#pragma DATA_SECTION(halHandle,"rom_accessed_data");

#endif

HAL_Handle halHandle;

#ifdef CSM_ENABLE

#pragma DATA_SECTION(gUserParams,"rom_accessed_data");

#endif

USER_Params gUserParams;

HAL_PwmData_t gPwmData = {_IQ(0.0), _IQ(0.0), _IQ(0.0)};

HAL_AdcData_t gAdcData;

_iq gMaxCurrentSlope = _IQ(0.0);

#ifdef FAST_ROM_V1p6

CTRL_Obj *controller_obj;

#else

#ifdef CSM_ENABLE

#pragma DATA_SECTION(ctrl,"rom_accessed_data");

#endif

CTRL_Obj ctrl; //v1p7 format

#endif

uint16_t gLEDcnt = 0;

volatile MOTOR_Vars_t gMotorVars = MOTOR_Vars_INIT;

#ifdef FLASH

// Used for running BackGround in flash, and ISR in RAM

extern uint16_t *RamfuncsLoadStart, *RamfuncsLoadEnd, *RamfuncsRunStart;

#ifdef CSM_ENABLE

extern uint16_t *econst_start, *econst_end, *econst_ram_load;

extern uint16_t *switch_start, *switch_end, *switch_ram_load;

#endif

#endif

#ifdef DRV8301_SPI

// Watch window interface to the 8301 SPI

DRV_SPI_8301_Vars_t gDrvSpi8301Vars;

#endif

#ifdef DRV8305_SPI

// Watch window interface to the 8305 SPI

DRV_SPI_8305_Vars_t gDrvSpi8305Vars;

#endif

#ifdef DRV8323_SPI

// Watch window interface to the 8301 SPI

DRV_SPI_8323_Vars_t gDrvSpi8323Vars;

#endif

_iq gFlux_pu_to_Wb_sf;

_iq gFlux_pu_to_VpHz_sf;

_iq gTorque_Ls_Id_Iq_pu_to_Nm_sf;

_iq gTorque_Flux_Iq_pu_to_Nm_sf;

// **************************************************************************

// the functions

void main(void)

{

uint_least8_t estNumber = 0;

#ifdef FAST_ROM_V1p6

uint_least8_t ctrlNumber = 0;

#endif

// Only used if running from FLASH

// Note that the variable FLASH is defined by the project

#ifdef FLASH

// Copy time critical code and Flash setup code to RAM

// The RamfuncsLoadStart, RamfuncsLoadEnd, and RamfuncsRunStart

// symbols are created by the linker. Refer to the linker files

memCopy((uint16_t *)&RamfuncsLoadStart,(uint16_t *)&RamfuncsLoadEnd,(uint16_t *)&RamfuncsRunStart);

#ifdef CSM_ENABLE

//copy .econst to unsecure RAM

if(*econst_end - *econst_start)

{

memCopy((uint16_t *)&econst_start,(uint16_t *)&econst_end,(uint16_t *)&econst_ram_load);

}

//copy .switch ot unsecure RAM

if(*switch_end - *switch_start)

{

memCopy((uint16_t *)&switch_start,(uint16_t *)&switch_end,(uint16_t *)&switch_ram_load);

}

#endif

#endif

// initialize the hardware abstraction layer

halHandle = HAL_init(&hal,sizeof(hal));

// check for errors in user parameters

USER_checkForErrors(&gUserParams);

// store user parameter error in global variable

gMotorVars.UserErrorCode = USER_getErrorCode(&gUserParams);

// do not allow code execution if there is a user parameter error

if(gMotorVars.UserErrorCode != USER_ErrorCode_NoError)

{

for(;;)

{

gMotorVars.Flag_enableSys = false;

}

}

// initialize the user parameters

USER_setParams(&gUserParams);

// set the hardware abstraction layer parameters

HAL_setParams(halHandle,&gUserParams);

// initialize the controller

#ifdef FAST_ROM_V1p6

ctrlHandle = CTRL_initCtrl(ctrlNumber, estNumber); //v1p6 format (06xF and 06xM devices)

controller_obj = (CTRL_Obj *)ctrlHandle;

#else

ctrlHandle = CTRL_initCtrl(estNumber,&ctrl,sizeof(ctrl)); //v1p7 format default

#endif

{

CTRL_Version version;

// get the version number

CTRL_getVersion(ctrlHandle,&version);

gMotorVars.CtrlVersion = version;

}

// set the default controller parameters

CTRL_setParams(ctrlHandle,&gUserParams);

// setup faults

HAL_setupFaults(halHandle);

// initialize the interrupt vector table

HAL_initIntVectorTable(halHandle);

// enable the ADC interrupts

HAL_enableAdcInts(halHandle);

// enable global interrupts

HAL_enableGlobalInts(halHandle);

// enable debug interrupts

HAL_enableDebugInt(halHandle);

// disable the PWM

HAL_disablePwm(halHandle);

#ifdef DRV8301_SPI

// turn on the DRV8301 if present

HAL_enableDrv(halHandle);

// initialize the DRV8301 interface

HAL_setupDrvSpi(halHandle,&gDrvSpi8301Vars);

#endif

#ifdef DRV8305_SPI

// turn on the DRV8305 if present

HAL_enableDrv(halHandle);

// initialize the DRV8305 interface

HAL_setupDrvSpi(halHandle,&gDrvSpi8305Vars);

#endif

#ifdef DRV8323_SPI

// turn on the DRV8305 if present

HAL_enableDrv(halHandle);

// initialize the DRV8305 interface

HAL_setupDrvSpi(halHandle,&gDrvSpi8323Vars);

#endif

// enable DC bus compensation

CTRL_setFlag_enableDcBusComp(ctrlHandle, true);

// compute scaling factors for flux and torque calculations

gFlux_pu_to_Wb_sf = USER_computeFlux_pu_to_Wb_sf();

gFlux_pu_to_VpHz_sf = USER_computeFlux_pu_to_VpHz_sf();

gTorque_Ls_Id_Iq_pu_to_Nm_sf = USER_computeTorque_Ls_Id_Iq_pu_to_Nm_sf();

gTorque_Flux_Iq_pu_to_Nm_sf = USER_computeTorque_Flux_Iq_pu_to_Nm_sf();

for(;;)

{

// Waiting for enable system flag to be set

while(!(gMotorVars.Flag_enableSys));

// Dis-able the Library internal PI. Iq has no reference now

CTRL_setFlag_enableSpeedCtrl(ctrlHandle, false);

// loop while the enable system flag is true

while(gMotorVars.Flag_enableSys)

{

CTRL_Obj *obj = (CTRL_Obj *)ctrlHandle;

// increment counters

gCounter_updateGlobals++;

// enable/disable the use of motor parameters being loaded from user.h

CTRL_setFlag_enableUserMotorParams(ctrlHandle,gMotorVars.Flag_enableUserParams);

// enable/disable Rs recalibration during motor startup

EST_setFlag_enableRsRecalc(obj->estHandle,gMotorVars.Flag_enableRsRecalc);

// enable/disable automatic calculation of bias values

CTRL_setFlag_enableOffset(ctrlHandle,gMotorVars.Flag_enableOffsetcalc);

if(CTRL_isError(ctrlHandle))

{

// set the enable controller flag to false

CTRL_setFlag_enableCtrl(ctrlHandle,false);

// set the enable system flag to false

gMotorVars.Flag_enableSys = false;

// disable the PWM

HAL_disablePwm(halHandle);

}

else

{

// update the controller state

bool flag_ctrlStateChanged = CTRL_updateState(ctrlHandle);

// enable or disable the control

CTRL_setFlag_enableCtrl(ctrlHandle, gMotorVars.Flag_Run_Identify);

if(flag_ctrlStateChanged)

{

CTRL_State_e ctrlState = CTRL_getState(ctrlHandle);

if(ctrlState == CTRL_State_OffLine)

{

// enable the PWM

HAL_enablePwm(halHandle);

}

else if(ctrlState == CTRL_State_OnLine)

{

if(gMotorVars.Flag_enableOffsetcalc == true)

{

// update the ADC bias values

HAL_updateAdcBias(halHandle);

}

else

{

// set the current bias

HAL_setBias(halHandle,HAL_SensorType_Current,0,_IQ(I_A_offset));

HAL_setBias(halHandle,HAL_SensorType_Current,1,_IQ(I_B_offset));

HAL_setBias(halHandle,HAL_SensorType_Current,2,_IQ(I_C_offset));

// set the voltage bias

HAL_setBias(halHandle,HAL_SensorType_Voltage,0,_IQ(V_A_offset));

HAL_setBias(halHandle,HAL_SensorType_Voltage,1,_IQ(V_B_offset));

HAL_setBias(halHandle,HAL_SensorType_Voltage,2,_IQ(V_C_offset));

}

// Return the bias value for currents

gMotorVars.I_bias.value[0] = HAL_getBias(halHandle,HAL_SensorType_Current,0);

gMotorVars.I_bias.value[1] = HAL_getBias(halHandle,HAL_SensorType_Current,1);

gMotorVars.I_bias.value[2] = HAL_getBias(halHandle,HAL_SensorType_Current,2);

// Return the bias value for voltages

gMotorVars.V_bias.value[0] = HAL_getBias(halHandle,HAL_SensorType_Voltage,0);

gMotorVars.V_bias.value[1] = HAL_getBias(halHandle,HAL_SensorType_Voltage,1);

gMotorVars.V_bias.value[2] = HAL_getBias(halHandle,HAL_SensorType_Voltage,2);

// enable the PWM

HAL_enablePwm(halHandle);

}

else if(ctrlState == CTRL_State_Idle)

{

// disable the PWM

HAL_disablePwm(halHandle);

gMotorVars.Flag_Run_Identify = false;

}

if((CTRL_getFlag_enableUserMotorParams(ctrlHandle) == true) &&

(ctrlState > CTRL_State_Idle) &&

(gMotorVars.CtrlVersion.minor == 6))

{

// call this function to fix 1p6

USER_softwareUpdate1p6(ctrlHandle);

}

}

}

if(EST_isMotorIdentified(obj->estHandle))

{

// set the current ramp

EST_setMaxCurrentSlope_pu(obj->estHandle,gMaxCurrentSlope);

gMotorVars.Flag_MotorIdentified = true;

if(Flag_Latch_softwareUpdate)

{

Flag_Latch_softwareUpdate = false;

USER_calcPIgains(ctrlHandle);

}

}

else

{

Flag_Latch_softwareUpdate = true;

// the estimator sets the maximum current slope during identification

gMaxCurrentSlope = EST_getMaxCurrentSlope_pu(obj->estHandle);

}

// when appropriate, update the global variables

if(gCounter_updateGlobals >= NUM_MAIN_TICKS_FOR_GLOBAL_VARIABLE_UPDATE)

{

// reset the counter

gCounter_updateGlobals = 0;

updateGlobalVariables_motor(ctrlHandle);

}

// update Iq reference

updateIqRef(ctrlHandle);

// enable/disable the forced angle

EST_setFlag_enableForceAngle(obj->estHandle,gMotorVars.Flag_enableForceAngle);

// enable or disable power warp

CTRL_setFlag_enablePowerWarp(ctrlHandle,gMotorVars.Flag_enablePowerWarp);

#ifdef DRV8301_SPI

HAL_writeDrvData(halHandle,&gDrvSpi8301Vars);

HAL_readDrvData(halHandle,&gDrvSpi8301Vars);

#endif

#ifdef DRV8305_SPI

HAL_writeDrvData(halHandle,&gDrvSpi8305Vars);

HAL_readDrvData(halHandle,&gDrvSpi8305Vars);

#endif

#ifdef DRV8323_SPI

HAL_writeDrvData(halHandle,&gDrvSpi8323Vars);

HAL_readDrvData(halHandle,&gDrvSpi8323Vars);

#endif

} // end of while(gFlag_enableSys) loop

// disable the PWM

HAL_disablePwm(halHandle);

// set the default controller parameters (Reset the control to re-identify the motor)

CTRL_setParams(ctrlHandle,&gUserParams);

gMotorVars.Flag_Run_Identify = false;

} // end of for(;;) loop

} // end of main() function

_iq gPotentiometer = _IQ(0.0);

uint32_t ringBuffer[50];

int counterr = 0;

#define LOW_BOUND ((360.0f)/(4096.0f))

#define UPPER_BOUND ((3988.0f)/(4096.0f))

#define MIDLOW_BOUND ((1460.0f)/(4096.0f))

#define MIDHigh_BOUND ((1490.0f)/(4096.0f))

#define GAS_Scale ((UPPER_BOUND - MIDHigh_BOUND))

#define BRAKE_Scale ((MIDLOW_BOUND - LOW_BOUND))

float gasvalue = 0;

#define maxAmp (15.0f)

uint32_t dutycc = 0;

uint32_t cyc = 0;

#define DUTY_MIN 58312

#define DUTY_MAX 120571

#define DUTY_MEAN 89350

uint32_t last = 0;

uint32_t min = 999999999,max = 0, mean = 0;

interrupt void mainISR(void)

{

cyc++;

dutycc = halHandle->capHandle->CAP2 - halHandle->capHandle->CAP1;

if (((int32_t) dutycc) > 0 && last != halHandle->capHandle->CAP2) {

last = halHandle->capHandle->CAP2;

if (dutycc >= DUTY_MEAN+500) {

gasvalue = ((float) dutycc - DUTY_MEAN) / ((float) DUTY_MAX - DUTY_MEAN) * maxAmp;

} else if (dutycc <= DUTY_MEAN-500){

gasvalue = ((float) dutycc - DUTY_MEAN) / ((float) DUTY_MEAN - DUTY_MIN) * maxAmp;

} else {

gasvalue = 0;

}

if (gasvalue < -0.5 & !gMotorVars.Flag_Run_Identify) {

gMotorVars.Flag_Run_Identify = 1;

gMotorVars.Flag_enableSys = 1;

}

if (abs(gasvalue) > maxAmp) {

gasvalue = 0;

}

ringBuffer[counterr++] = dutycc;

if (counterr == 50) {

counterr = 0;

}

uint32_t i = 0, ccc;

for (i = 0; i < 50; i ++) {

ccc += ringBuffer[i];

}

mean = (uint32_t) ((double) ccc)/50.0;

}

gMotorVars.IqRef_A = _IQ(gasvalue);

// toggle status LED

if(++gLEDcnt >= (uint_least32_t)(USER_ISR_FREQ_Hz / LED_BLINK_FREQ_Hz))

{

HAL_toggleLed(halHandle,(GPIO_Number_e)HAL_Gpio_LED2);

gLEDcnt = 0;

}

// acknowledge the ADC interrupt

HAL_acqAdcInt(halHandle,ADC_IntNumber_1);

// convert the ADC data

HAL_readAdcData(halHandle,&gAdcData);

// run the controller

CTRL_run(ctrlHandle,halHandle,&gAdcData,&gPwmData);

// write the PWM compare values

HAL_writePwmData(halHandle,&gPwmData);

// setup the controller

CTRL_setup(ctrlHandle);

return;

} // end of mainISR() function

void updateGlobalVariables_motor(CTRL_Handle handle)

{

CTRL_Obj *obj = (CTRL_Obj *)handle;

int32_t tmp;

// get the speed estimate

gMotorVars.Speed_krpm = EST_getSpeed_krpm(obj->estHandle);

// get the torque estimate

gMotorVars.Torque_Nm = USER_computeTorque_Nm(handle, gTorque_Flux_Iq_pu_to_Nm_sf, gTorque_Ls_Id_Iq_pu_to_Nm_sf);

// when calling EST_ functions that return a float, and fpu32 is enabled, an integer is needed as a return

// so that the compiler reads the returned value from the accumulator instead of fpu32 registers

// get the magnetizing current

tmp = EST_getIdRated(obj->estHandle);

gMotorVars.MagnCurr_A = *((float_t *)&tmp);

// get the rotor resistance

tmp = EST_getRr_Ohm(obj->estHandle);

gMotorVars.Rr_Ohm = *((float_t *)&tmp);

// get the stator resistance

tmp = EST_getRs_Ohm(obj->estHandle);

gMotorVars.Rs_Ohm = *((float_t *)&tmp);

// get the stator inductance in the direct coordinate direction

tmp = EST_getLs_d_H(obj->estHandle);

gMotorVars.Lsd_H = *((float_t *)&tmp);

// get the stator inductance in the quadrature coordinate direction

tmp = EST_getLs_q_H(obj->estHandle);

gMotorVars.Lsq_H = *((float_t *)&tmp);

// get the flux in V/Hz in floating point

tmp = EST_getFlux_VpHz(obj->estHandle);

gMotorVars.Flux_VpHz = *((float_t *)&tmp);

// get the flux in Wb in fixed point

gMotorVars.Flux_Wb = USER_computeFlux(handle, gFlux_pu_to_Wb_sf);

// get the controller state

gMotorVars.CtrlState = CTRL_getState(handle);

// get the estimator state

gMotorVars.EstState = EST_getState(obj->estHandle);

// Get the DC buss voltage

gMotorVars.VdcBus_kV = _IQmpy(gAdcData.dcBus,_IQ(USER_IQ_FULL_SCALE_VOLTAGE_V/1000.0));

return;

} // end of updateGlobalVariables_motor() function

void updateIqRef(CTRL_Handle handle)

{

_iq iq_ref = _IQmpy(gMotorVars.IqRef_A,_IQ(1.0/USER_IQ_FULL_SCALE_CURRENT_A));

// set the speed reference so that the forced angle rotates in the correct direction for startup

if(_IQabs(gMotorVars.Speed_krpm) < _IQ(0.01))

{

if(iq_ref < _IQ(0.0))

{

CTRL_setSpd_ref_krpm(handle,_IQ(-0.01));

}

else if(iq_ref > _IQ(0.0))

{

CTRL_setSpd_ref_krpm(handle,_IQ(0.01));

}

}

// Set the Iq reference that use to come out of the PI speed control

CTRL_setIq_ref_pu(handle, iq_ref);

return;

} // end of updateIqRef() function

//@} //defgroup

// end of file

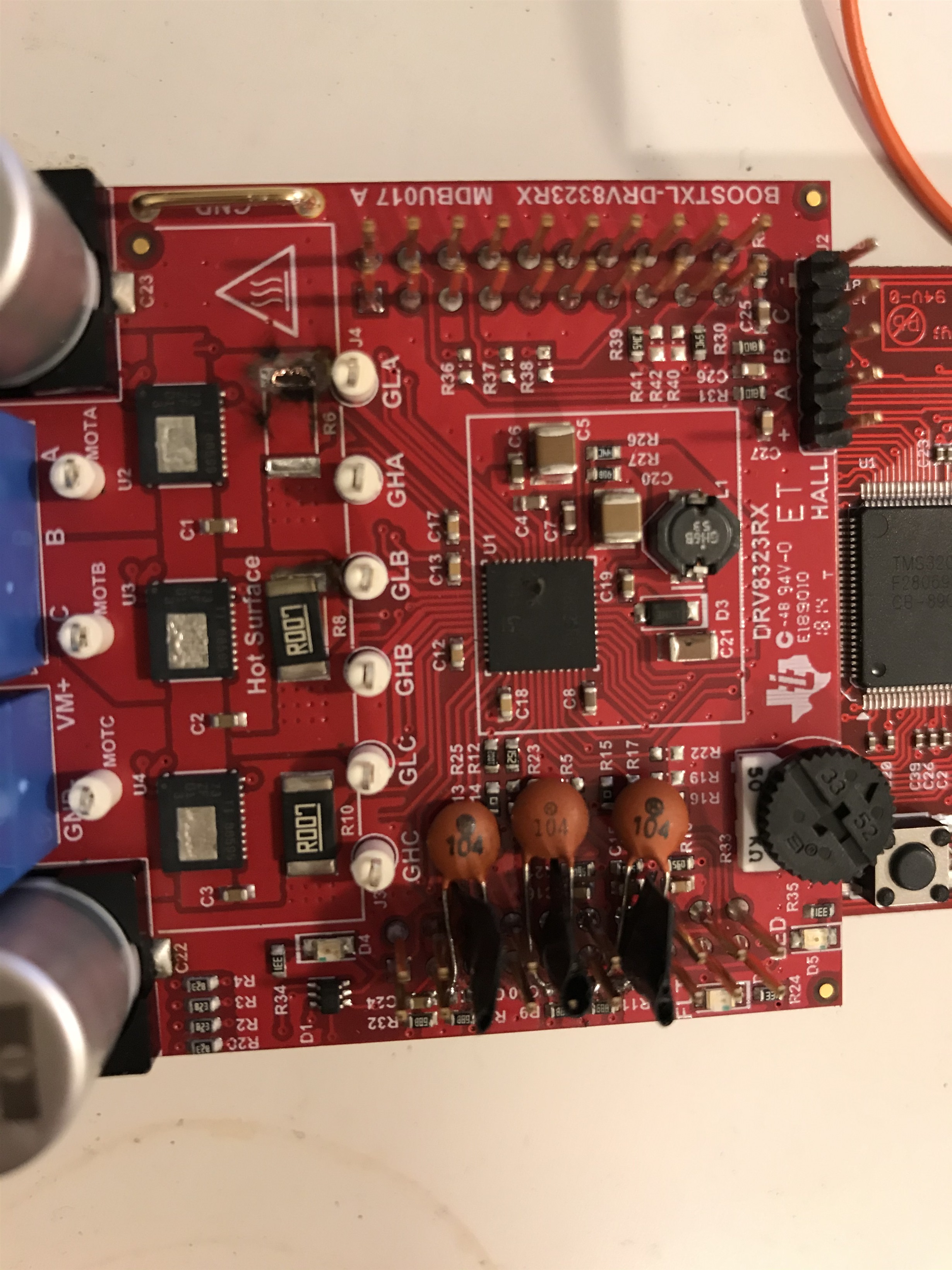

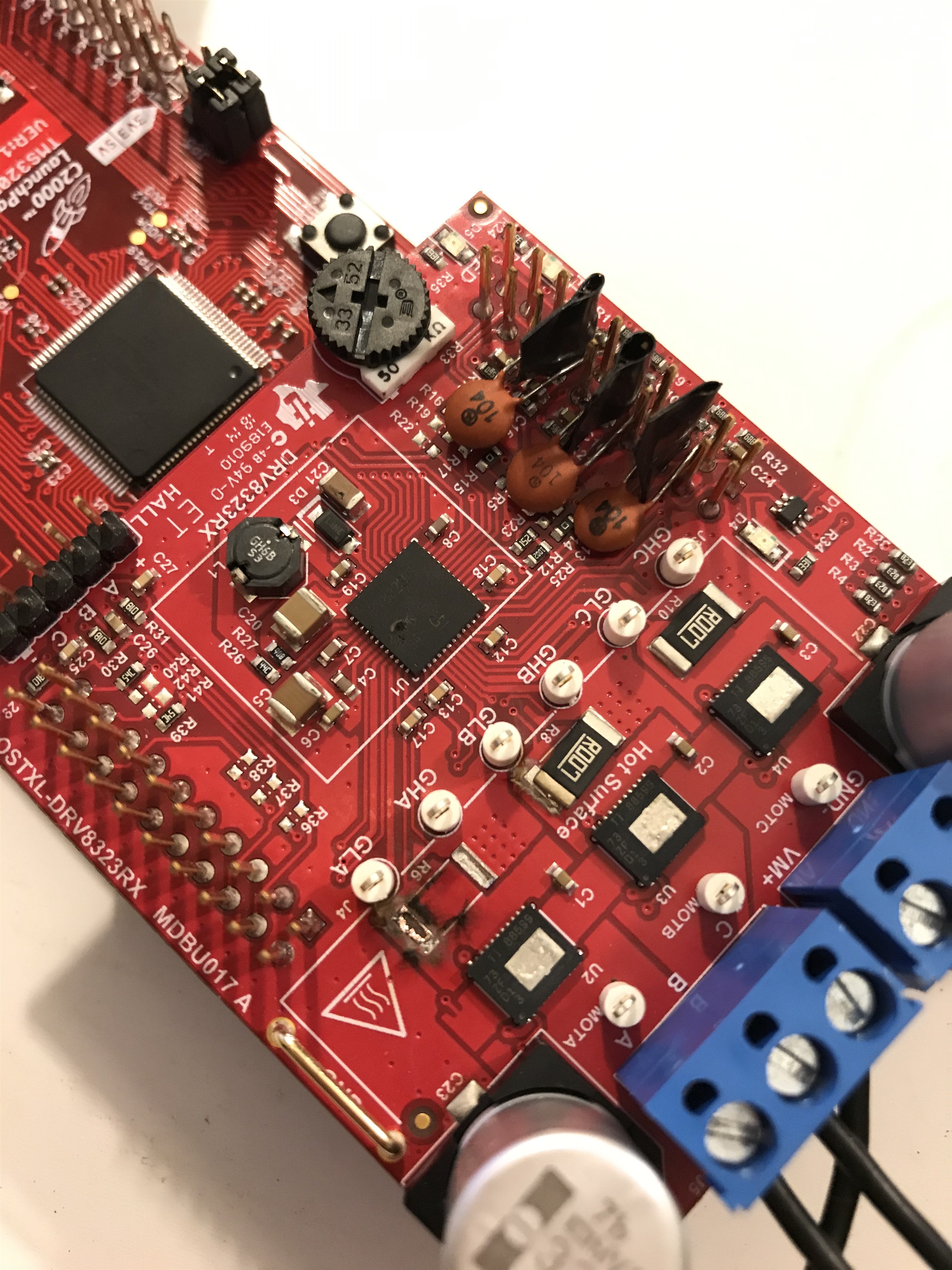

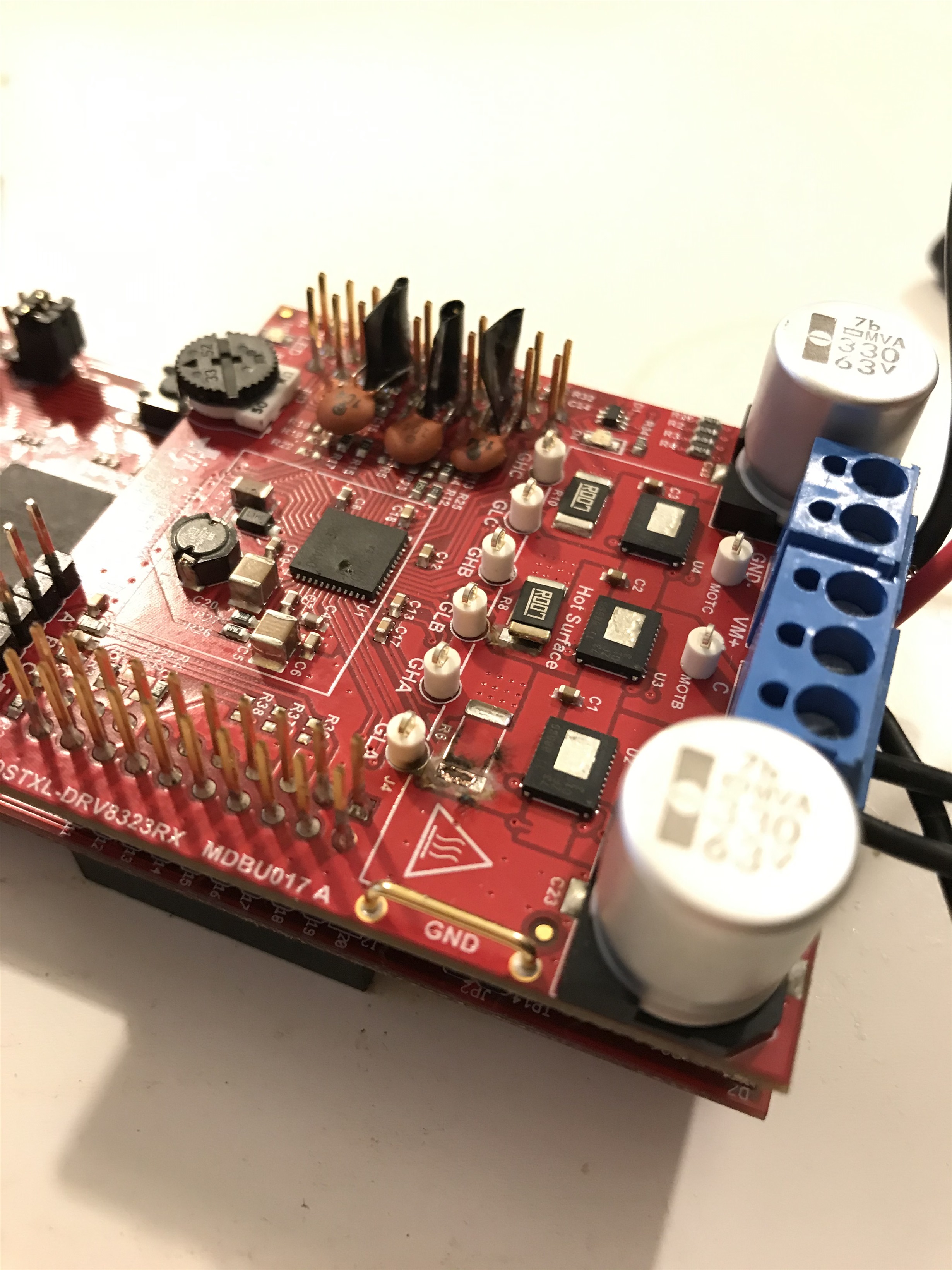

I had an RC controller delivering the signal to the launchpad, and it worked fine for about three-quarters throttle, which corresponds to about 10 amps. The operation is done at 48v. The load I have is like an ebike, and what follows happened when the motor is at rest. I pushed it to up to 15 amps full throttle, the motor makes a loud high-frequency sound for about two seconds and the fault light lights up and the motor becomes disarmed. But I tried it a second-time for full-throttle, 15 amps ref, and the motor made the same sound again with the fault light lighting up but it didn't stop making the noise. I panicked and quickly unplugged the power, then the shunt resistor exploded. I am not sure what happened first (the sparks/explosion or the unplugging), but I think the sparks ignited instantly after I unplugged the power. The DRV also appears to be damaged. The whole process happened in about 5 seconds, from motor noise to evm exploding.

The motor runs under no load, and I am confident that the power and the motor are not the problem.

The 28069m seems to be fine, but the DRV evm definitely seems toasted. The code is programmed in flash if that matters.

This is my second DRV8323RS as I the first one I bought had some problems getting the motor to spin even after I soldered the caps.