Other Parts Discussed in Thread: USB2ANY, DRV10983-Q1, DRV10987

Team,

My customer is looking for help:

We have encountered a failure mode involving the DRV10983Q1EVM (evaluation board) and the DRV109XX EVM software and we wondered if any of your engineers could help us figure out the possible cause.

Currently, when a speed command is given over I2C to the evaluation board, the BLDC motor will immediately ramp up to max speed after crossing the Open loop to Closed loop threshold. Furthermore it will not respond to any subsequent speed commands given.

Through our debugging process, we have found out the following:

- The supply voltage VCC as read by the board is 11.8V when provided with 13V via power supply. 13V is read via multimeter on the VCC pin of the DRV10983Q1.

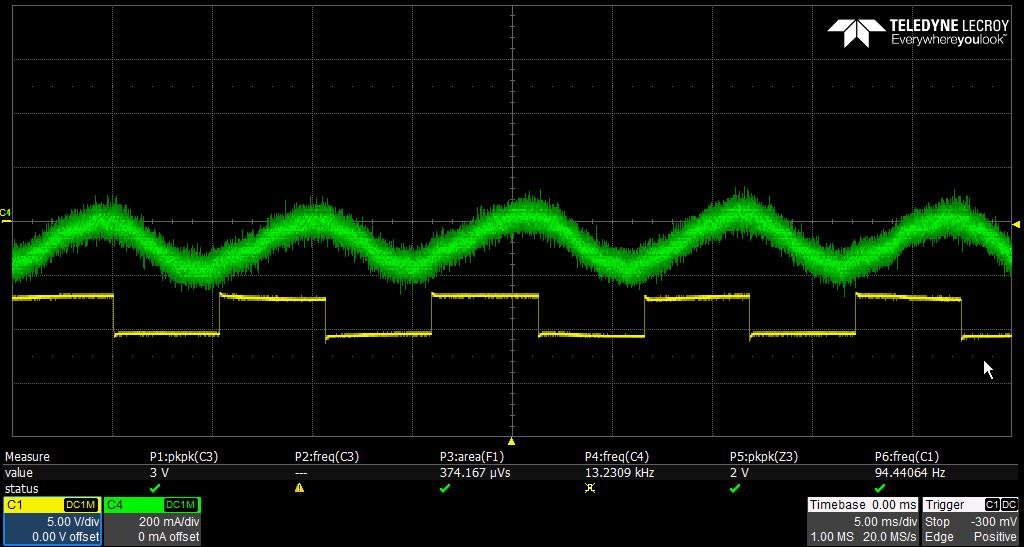

- The RPM calculated by the board is about 50% higher. For instance it reports 1800rpm for max speed when our motor is running at 1200rpm as confirmed via oscilloscope.

- If mechanical AVS is unchecked/disabled, then the board will respond normally to various I2C speed commands. However, the voltage and speed readings are still as seen in #1 and #2.

Two different EVM boards have exhibited the same symptoms described above. For the previous 6 months, we had been manually setting the registers on the TI DRV109XX EVM software without encountering any issues. Then after making use of the configuration file, EEWRITE, and EEREFRESH features of the DRV109XX EVM software, we first noticed the abnormal behavior on both boards. The software version used was 3.2.2.0.

We have since updated to the latest software version of 3.3.4, but setting the registers manually does not fix the issue.

Are there any known issues that could cause this? If you need any additional information please let me know.

Thanks

Viktorija