Dear. experts

I'm using LM98725 on MFP scanner.

I have few question about it.

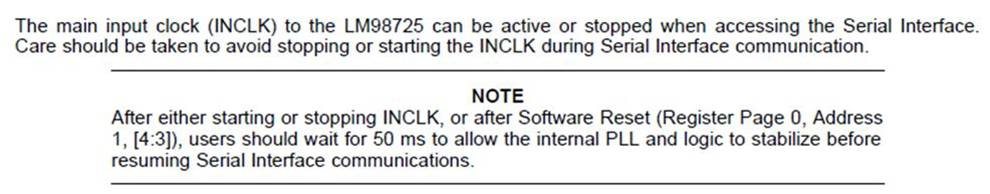

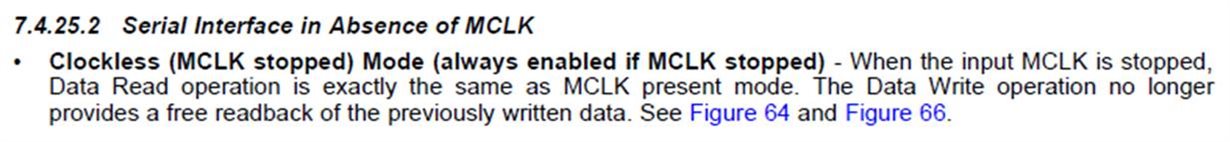

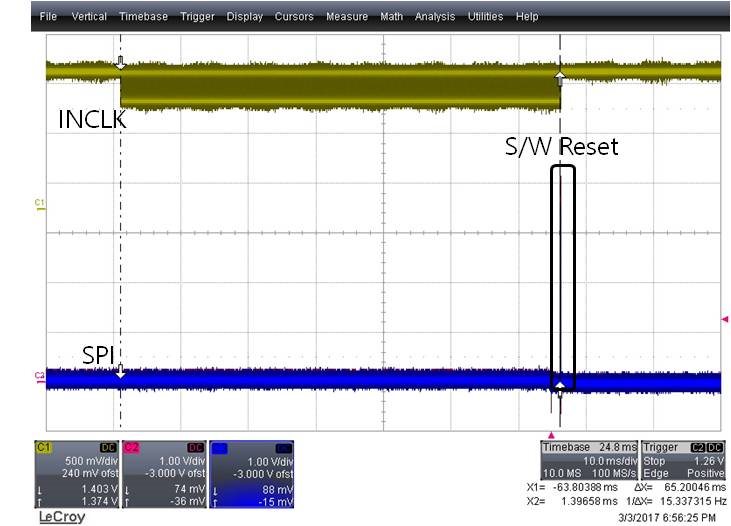

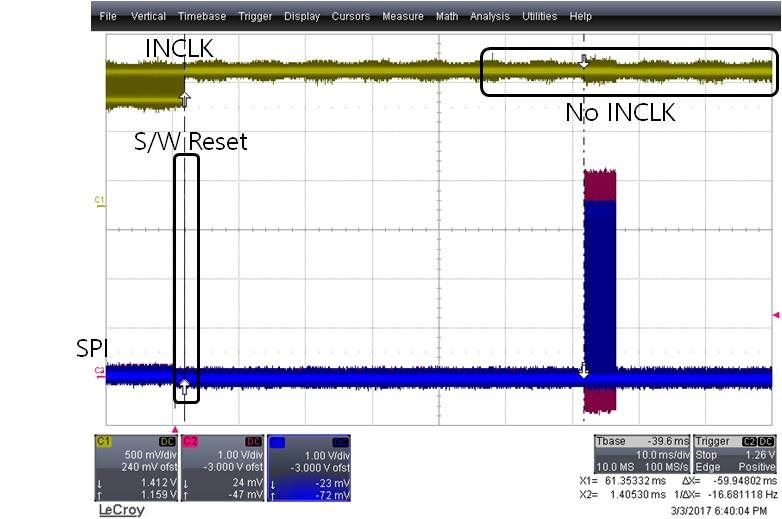

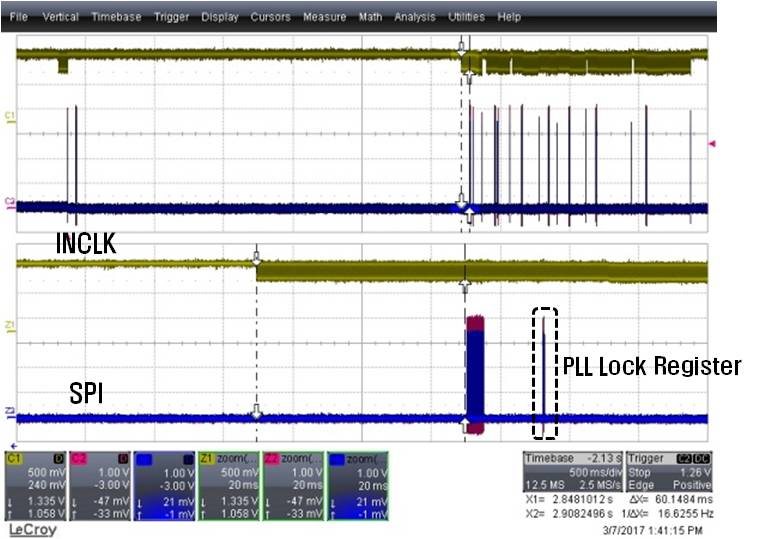

1. When I start MFP and LM98725, sometimes the PLL don't get locked.

But if I restart MFP, it works well.

Have you ever had any issue about pll unlock? If you had, how did you solve this problem?

- INCLK is not stopped, when SoC is writting value of register by SPI.

2. On datasheet page 6, 6.1 absolute maximum ratings, the soldering temperature is max. 235℃.

If package temperature of AFE is exceed 235℃ during reflowing, is LM98725 possible to be damaged?

I did ABA test, it looks like AFE has been damage, sometimes the PLL don't get locked.

Sorry about my bad English, please reply about my question.

Best Regard.