Hi

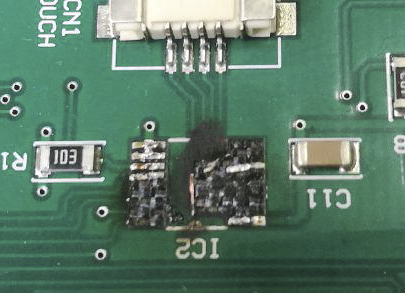

We use ADS7846 in our project from several years. Recently, we have received, to repaire it, some circuits with ADS7846 completely burned without any apparently cause. The packaging was been deformed because of overheat or explosion. Also pcb and traces under the chip are burned. All the rest of circuitry, display and touchscreen are functioning.

In the past, also other chips were failed, but never in this too energetic way.

Which could be the cause?

Is it possible introducing some protection to avoid such fail?

Thanks for any help.

Regards