Other Parts Discussed in Thread: BQSTUDIO

Hello again,

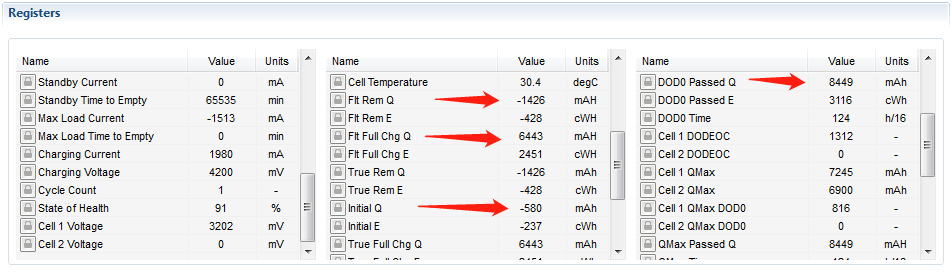

I have some boards with BQ28Z610, programmed like all the others but with strange low values of FCC against the DC value.

Analyzing the detail with bqStudio, I have noticed that, with GAUGE_ENABLED, while the load is applied, the value of remaining capacity is fixed for long time, (it is not decreasing like I am expecting) but the value of passed Q is increasing.

the Update Status is 0e, the QMax is higher than the Design Capacity ....

What the hell is happening?

Please help me, it is urgent.....