Other Parts Discussed in Thread: BQSTUDIO, EV2400, , BQ27000

Here is the story, we have one product (CN51) that battery using gas gauge bq27545, it communicates with our terminal (android OS) via HDQ protocol.

The problem is I can’t retrieve correct data from gauge, I try to read registers and some control command, but failed, then I add some delay between each read, now I can read registers but not CONTROL sub commands. I tried different delay but still cannot read successful. Do you have suggestions on this problem?

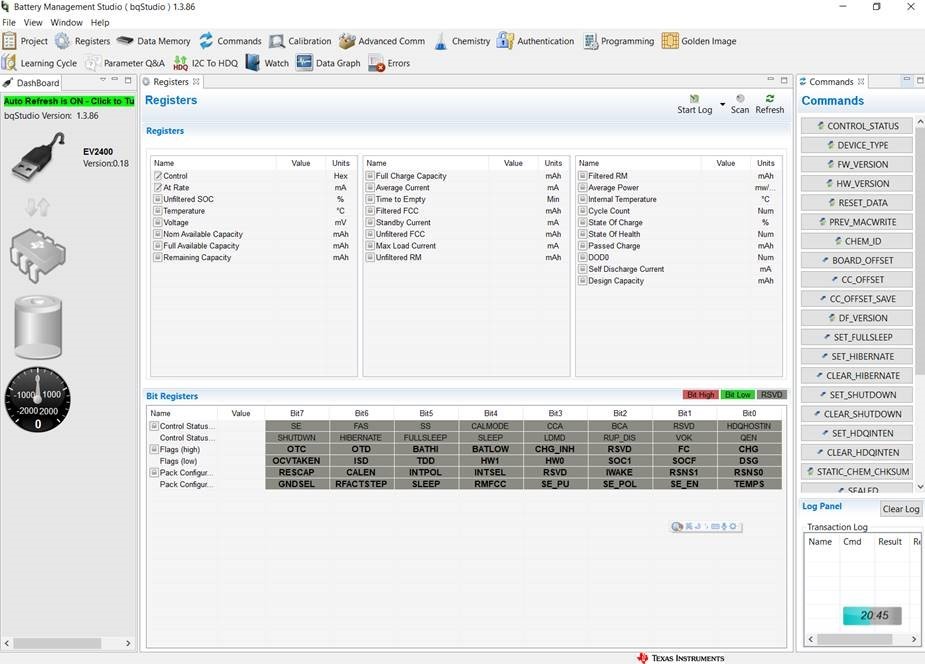

Now have EV2400 in hand, and downloaded bqstudio, but can't connect PC-EV2400-Battery successful, could you please suggest this part also?