Other Parts Discussed in Thread: BQSTUDIO

Hi,

I'm looking to calibrate the bq34z100-g1 (voltage, current, temperature) using a python script for production use.

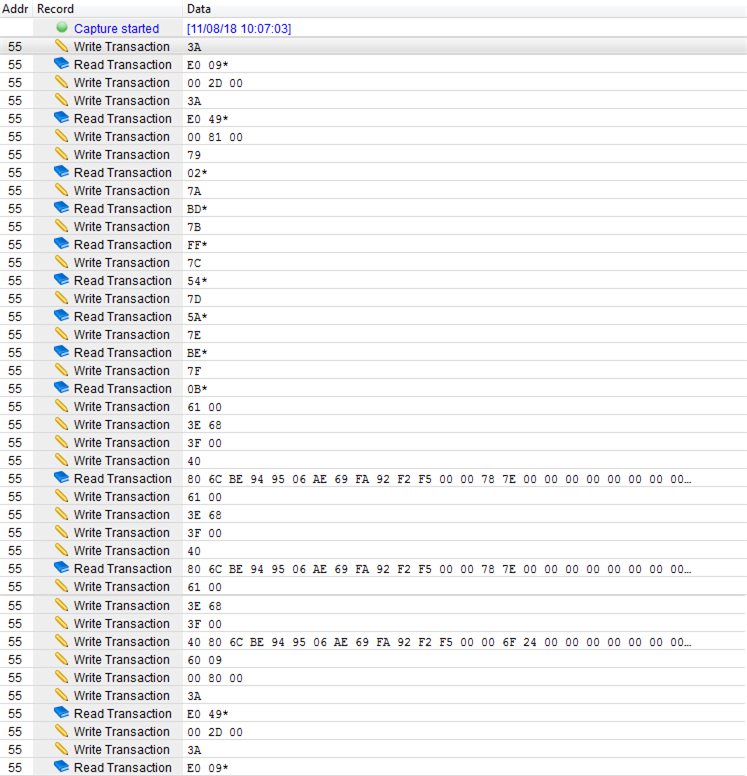

I've used Battery Management Studio to calibrate the voltage, and viewed the generated i2c commands, but I'm not making sense of it.

Can you explain the process or Is there documentation for this?

Thanks,

Andy