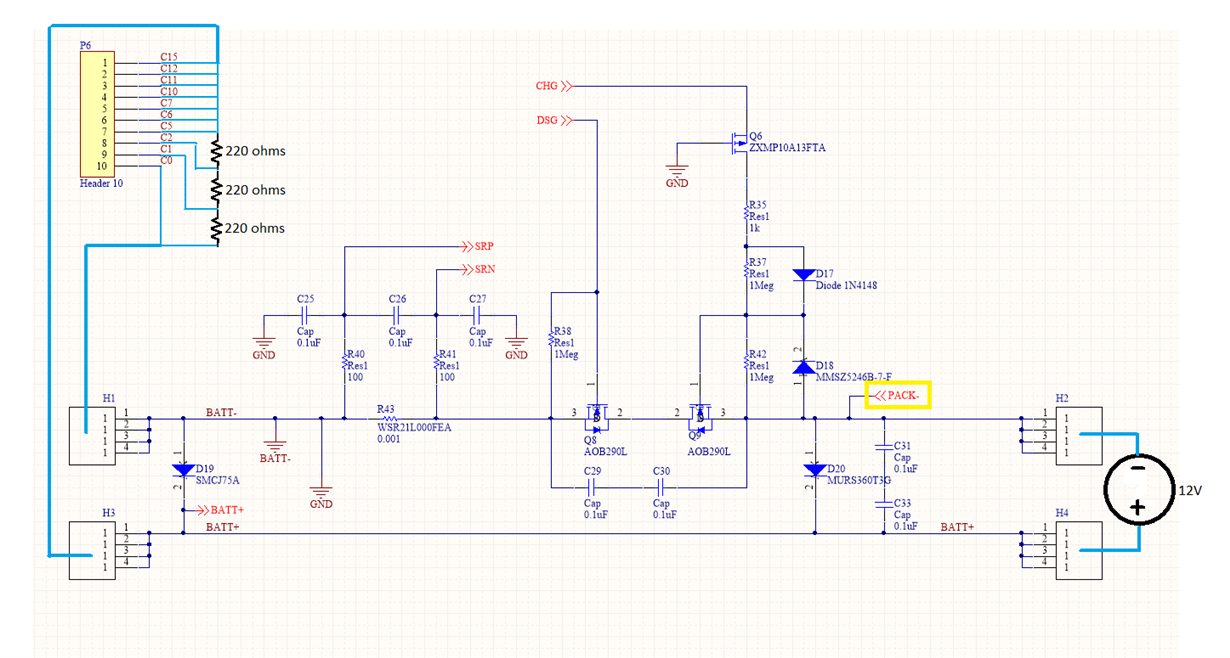

Good day, I built a BMS board in which I use the BQ76940 and a PIC24 as microcontroller. Here is the schematic (I used Altium): /cfs-file/__key/communityserver-discussions-components-files/196/0383.Schematic.rar

Is it possible to power up the board using a 12Vdc battery (instead of 36V, as I currently don't have a dc supply)? I just wanted to check if the BQ76940 REGOUT produces 3.3V which should power up my microcontroller. However, I do not get any voltage from REGOUT. Checking REGSRC also, I do not get any voltage. And so I thought maybe I need 36V for it to work.

Thanks,

Robert

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.