Hello,

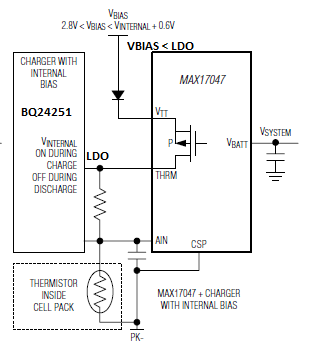

we are developing single cell liion charger + fuel gauge solution. We need both charger and fuel gauge to measure temperature of the pack and we would like to share single thermistor by both charger and fuel gauge. Our fuel gauge is MAX17047 and our charger is TI BQ24251.

Fuel gauge measures temperature on AIN pin by temporarily (for 10 ms every 1400 ms) connecting bias voltage to THRM pin.

Charger needs to continuously supply thermistor from LDO pin.

There will be no problem, when LDO is on, because VBIAS < LDO. However, when the charger will be off and LDO will also be off, VBIAS will be shorted to the LDO of the charger. We measured 100 - 150 uA current flowing into LDO in this situation. Is it safe?

Is there a better solution for thermistor sharing between BQ24251 and fuel gauge?