Hi all,

We are using BQ34Z110 fuel gauge in one of our designs to operate with a 12V 7AH lead acid battery. We have completed the configuration,calibration part & now want to run a optimization cycle.

The problem we are facing is that when we send a IT_enable command, only QEN flag is getting set, but VOK flag is always zero.

Below post suggests 3 conditions for VOK to be set: http://e2e.ti.com/support/power_management/battery_management/f/180/t/159009.aspx

In our case

1) dV/dT<4uV/sec holds good since there is no change in measured voltage.

2) Voltage measured is outside disqualification window

3) Temperature is 31.8C

With all these conditions, sending IT_enable command is not setting the VOK flag even though update status register reads 0x04.

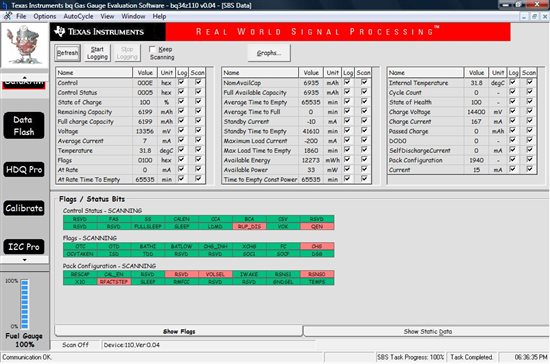

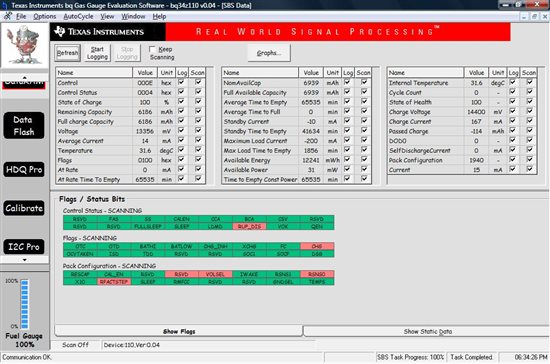

Below are the snapshots of DATARAM registers both before & after sending IT_enable command.

Before Sending IT_Enable :

After sending IT_Enable :

One more observation is that, the RUP_DIS flag is always "1" & OCVTAKEN is "0".

For VOK flag to set is there a need of OCVTAKEN being "1" ?

Average current is 16mA and we have set quit current to be 40mA. Thus battery should be in relaxation mode.

Is our assumption correct?

Please suggest.

Thanks,

Suresha N S