I'm currently in the process to make a golden image for one of our customer.

The battery pack is build around 2 Panasonic NCR18650A in serial and a small board build around a BQ20Z75v-180.

We use an EV2300 USB-based PC interface and the software called 'Texas Instrument bq Gas Gauge Evaluation Software - bq20z75v1.81 - [bqEasy]' to communicate with the battery pack.

We use a charger build around a LT3651 to charge this battery pack. The charge voltage is 8.2V. Using bqEasy software and logging a complete charge, I was able to determine that when charge stopped, voltage was 8.147V and current was 160 mA.

I use bqEasy to generate a golden image. I answer all questions about my application, chose the right chemistry. After that, I adjust Taper Current from 150mA to 200 mA and Charging Voltage from 8400 mV to 8200mV so the BQ20z75 can correctly detect the end of charge when using our charger. BQ20z75 correctly detect end of charge because bit 5 of BatteryStatus() is set (0x40E0).

If I use the ManufacturerAccess() to read Chemistry ID I read 0232.

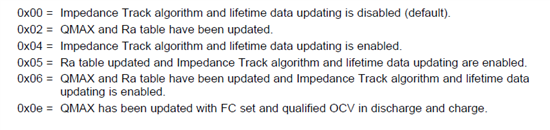

Before I start the Learning Cycle I validated that UpdateStatus() was 0.

After initiated the Learning Cycle, UpdateStatus() switch to 4.

I use an active load to discharge the battery pack with a current of 640 mA. The load is turned on and off using a FET connected to the EV2300, I respect the 2 hours after end of charge before initiating the discharge and the 5 hours before starting charge after end of discharge.

In order to complete the Learning Cycle, UpdateStatus() is supposed too turn to 6... but this doesn't append and I made many charge discharge cycle.

Have any idea what append?

Bests regards,

Marc