Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO, GPCRA0

Hi,

I followed the optimization cycle described here :

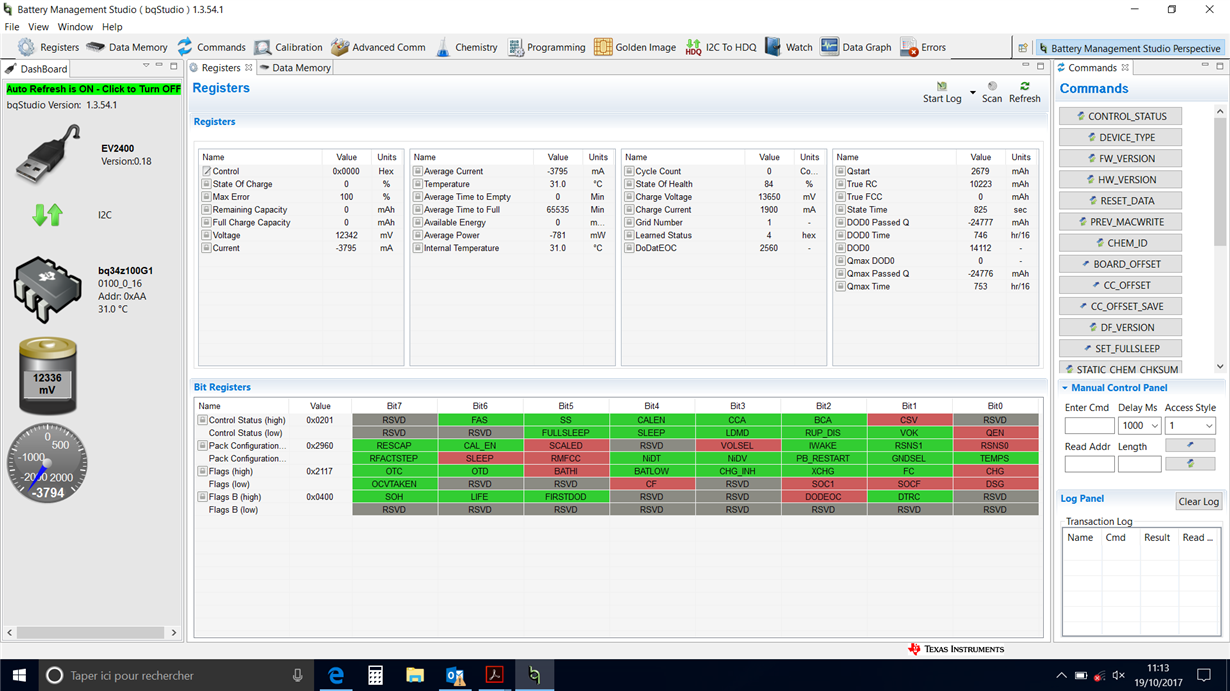

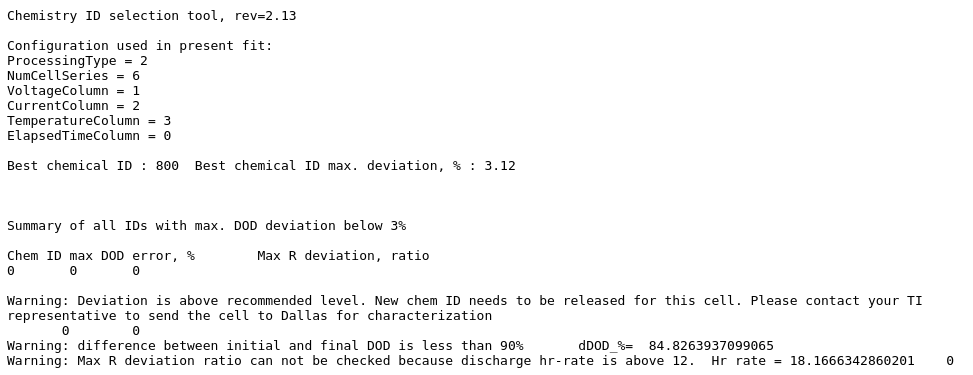

I have configured the dataflash using the datasheet and the slua664 file. I chose the appropriate chemistry ID= 0x800: I have a lead acid battery 38Ah with valve regulated.

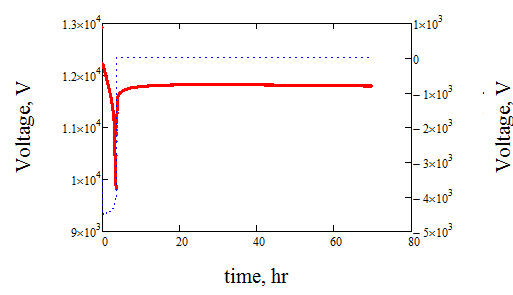

I have proceeded a charge cycle in first, I waited for OCVTAKEN flag to be set but it never changed. ( I waited for 24h...)

Questions:

1 Is my dataflash configuration ok?

2 Is it normal the Ra-Table has changed when I activated the Impedance track?

3 When I started the discharge cycle, the communication with the IC is lost, and the state of charge jump to 0%

Thanks in advance for your answer