Other Parts Discussed in Thread: GPCRA0

Hi,

We are using a BQ34Z100-G1 fuel gauge for a lithium ion battery management system.

We successfully performed a learning cycle on some brand new cells and have been using that golden image successfully for some time now.

In our application we are starting to use second life cells which have been in service in other applications before we use them in our product meaning that their capacity is not what it once was. As we have no control over their previous life, each set of cells will likely be at a different SOH so we would like the BQ chip to re-learn the cell capacity. To do this we have enabled the Impedance Track Algorithm with the IT ENABLE command.

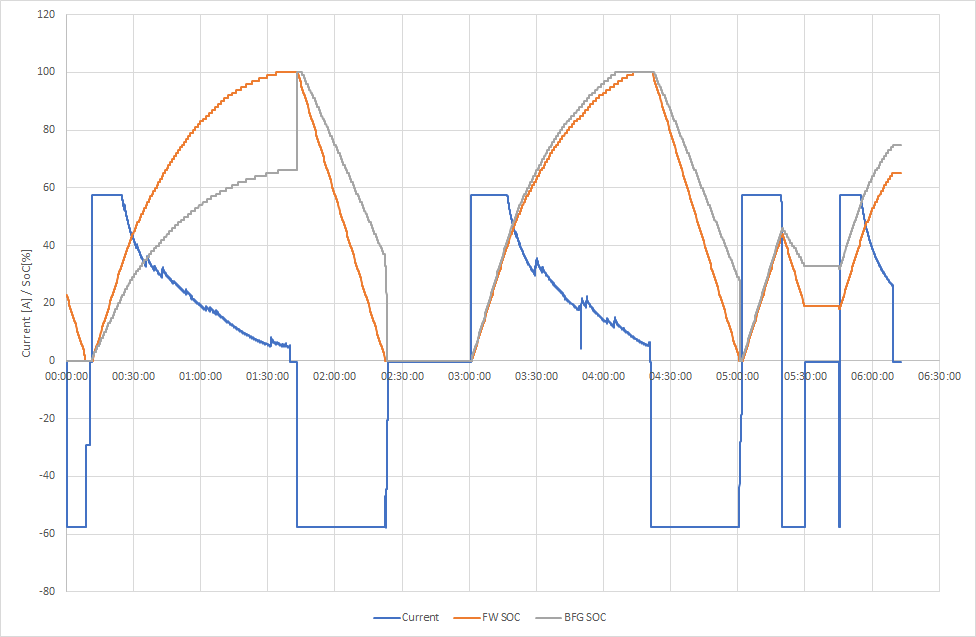

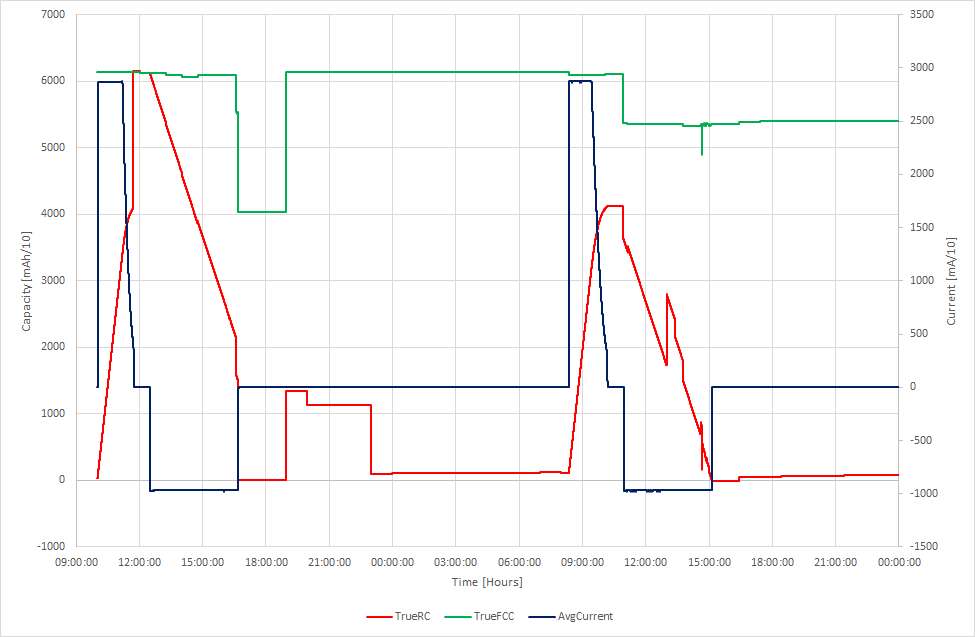

After one full cycle, the SoC appears to track well on a charge (suggesting it has learnt a new capacity) however the SoC on discharge appears to be very inaccurate (it looks as if it thinks its a brand new cell). This appears to be regardless of whether its a full charge or not.

Over a number of cycles it appears to be improving however we would like it to learn as quickly as possible for our end user.

Are there any settings or procedures which will allow the BQ chip to learn the new capacity quicker? or for it to learn discharge as fast as charge?

Thanks,

James

PS. I've attached a graph of our charge discharge cycles. We have plotted the BFG SoC along with a SoC we calculate in the microcontroller Firmware based on a simple coulomb counting algorithm.