Other Parts Discussed in Thread: BQSTUDIO, GPCCHEM, BQ34Z100

Hello there,

At this point I am clueless on why is my BQ34Z100-G1 config still not working. The SoC shows 0% all the time, even thought the batteries are fully charged. I will describe my application here with all the steps I took in order to configure the device. I would appreciate all help regarding this topic.

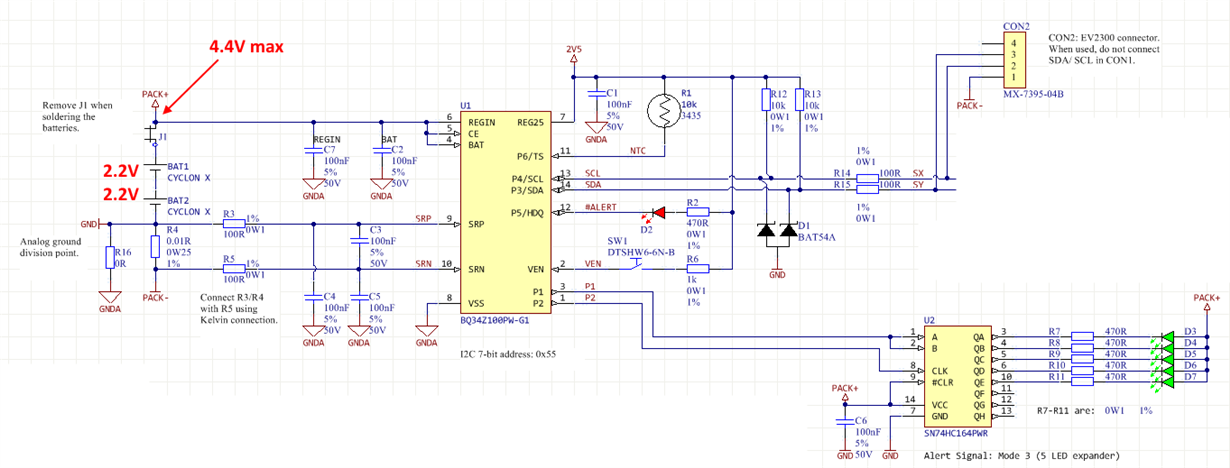

Here is the relevant chunk of my schematics. I have removed all parts that could make it more difficult to read it:

The parameters for a single cell (there are 2 connected in series in the design) in my application are the following:

- Max charge voltage: 2.2 V

- Min charge voltage: 1.65 V

- Capacity: 5000 mAh

- Max energy: 5000 mAh * 2.2 V * 2 cells = 22000 mWh

- Exact cell model: Cyclon X from Enersys: www.batterystore.com/.../

Those are the steps I took in order to configure the device (basing on SLUSBZ5B –JANUARY 2015–REVISED JULY 2016):

- I entered the Design Capacity: 5000

- I entered the design energy: 22000

- I entered the Cell charge Voltage Tx-Ty: 4000, 4200, 4400

- I configured the LED configuration for 5 leds.

- I configured Alert to turn the LED on when battery is discharged.

- I entered series cells number. Here I tried 1 and 2, since I did not know how to threat this config. At the moment I have 1 cell.

- I set the pack configuration for single cell, since I have no external divider.

- I left load select and load mode alone.

- I entered cell terminate voltage: 4400

- I left Quit current alone.

- I entered Wmax Cell 0: 5000

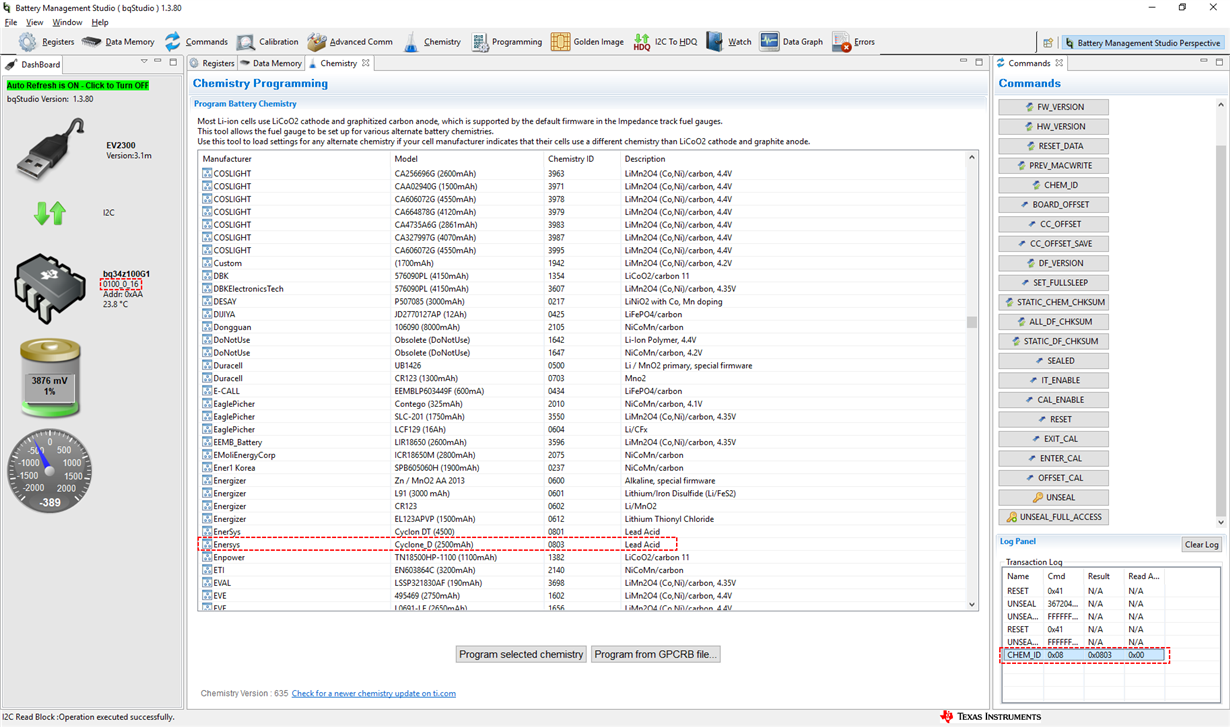

- I have choosen the Chemical ID for the battery from the available ones in the battery studio. I have choosen the one for Enersys Cyclon D. Its the same battery as mines, but its 2500 mAh instead of 5000 mAh. Is this approach correct?

- I calibrated the voltage and temperature.

- At this moment I wanted to run an optimization cycle but my SoC is invalid. Doesnt matter if I charge or discharge the battery, its 0 %.

- I left the battery chemistry configuration part alone, as there were no special configs for my type of battery described.

And here I am, not knowing whats going on, needing the gauge to work for more than 2 weeks now already...

I would really appreciate your help here, the case is really urgent for me.