Other Parts Discussed in Thread: BQSTUDIO, BQ40Z50-R2

I have custom charger design, based on BQ40Z60 evaluation board, with changes:

- without all U1 protection circuit

- without precharge circuit: F1, Q7, C10, R18, R22

- AFEFUSE pin tied to GND

- R14 changed to 1K (we have high voltage drop on ACP pin after charge was enabled)

- C18, C20, C24, C25, C27 changed to 4,7uF/25V

- no Q10-Q13 led circuit

- voltage divider: R21 = 330k, sum of R26-R29 = 24k

- BQ40Z60 firmware: bq40z60_v0_15_build_21

- connected cells: 4x parallel NCR18650GA-Panasonic with thermistor and cables for balancer

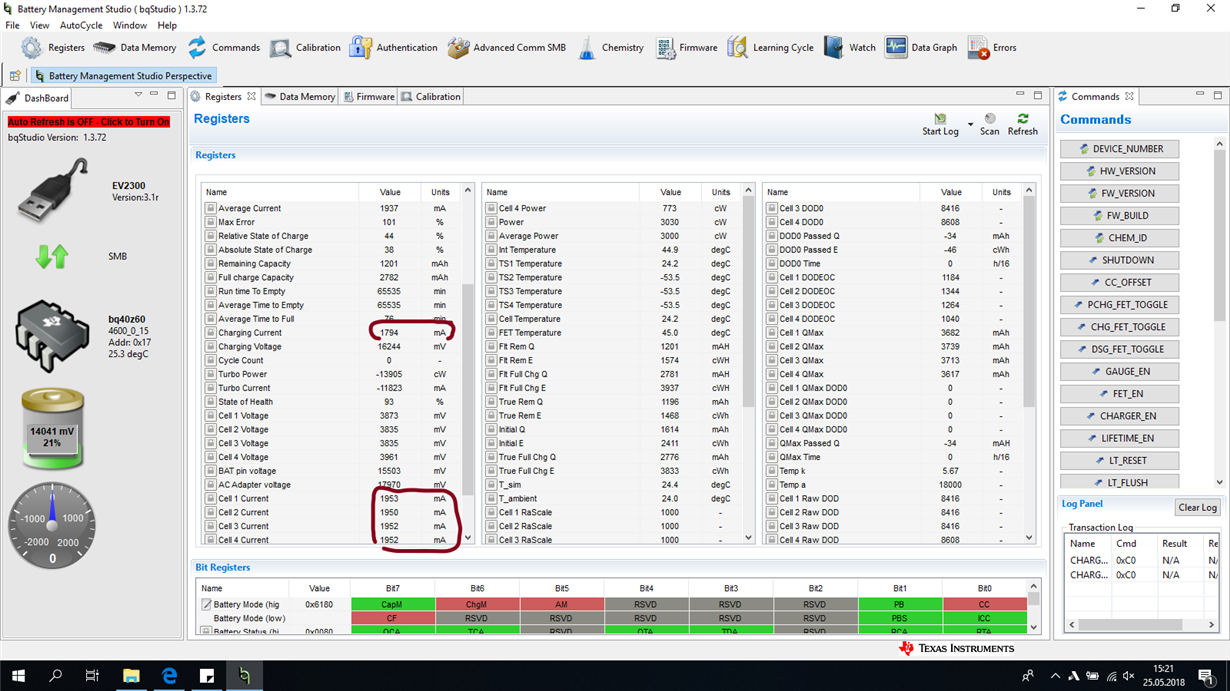

We have problem witch charging currents mismatch. BQ studio is reporting charging current to 1794mA, but for cell1-4 show about 1940mA. But to the cells is going about 2300mA (we connected 0.01R to +V4 cell, and measure voltage drop).

All voltages are calibrated and reported properly.

When I want to calibrate current (using that add-on 0.01Rfor metering), CC Gain, and Capacity Gain drops to 4.324. And all reported currents got messed up.

But sometimes I have "good" board, charging current 1794mA is almost the same as cell1-4 currents, but physically it delivers to battery about 2000mA. It works on the same golden image as other boards, only voltage calibration was done before metering.

How to fix that?