Other Parts Discussed in Thread: GPCRB, GPCCHEM, GPCCEDV, BQ34110, , GPCRA0, BQSTUDIO, EV2400

| Your Gauging Parameter Calculator report is here. |

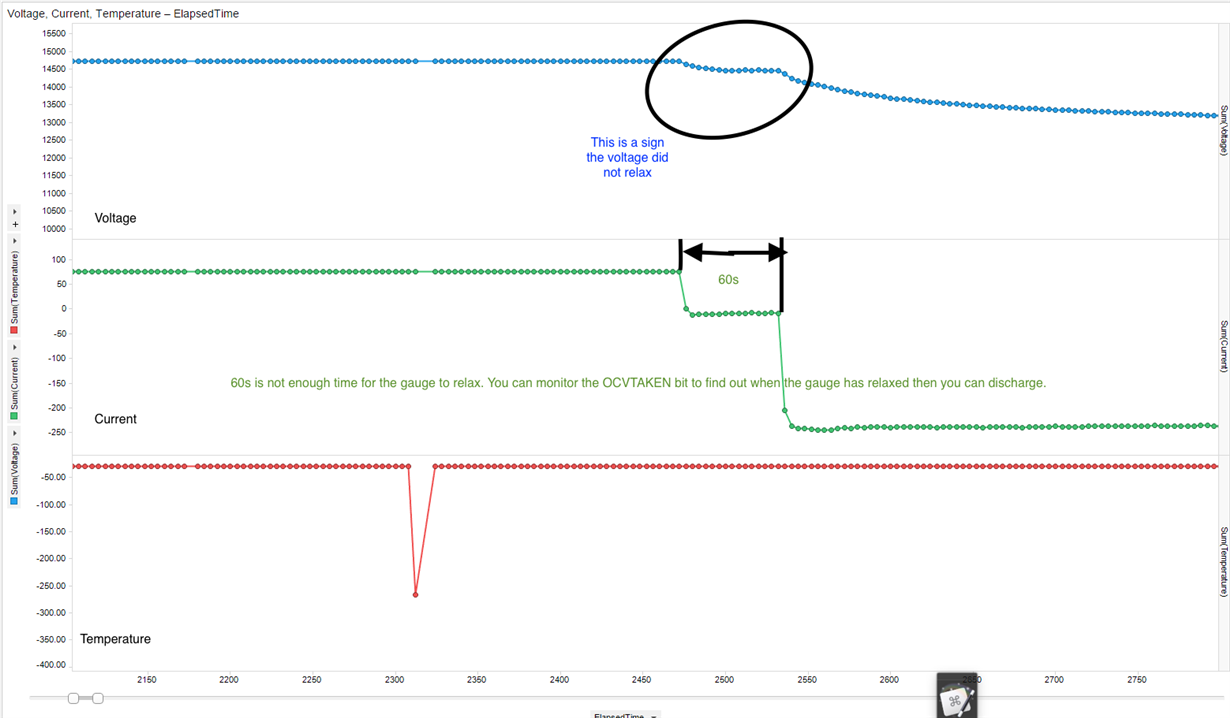

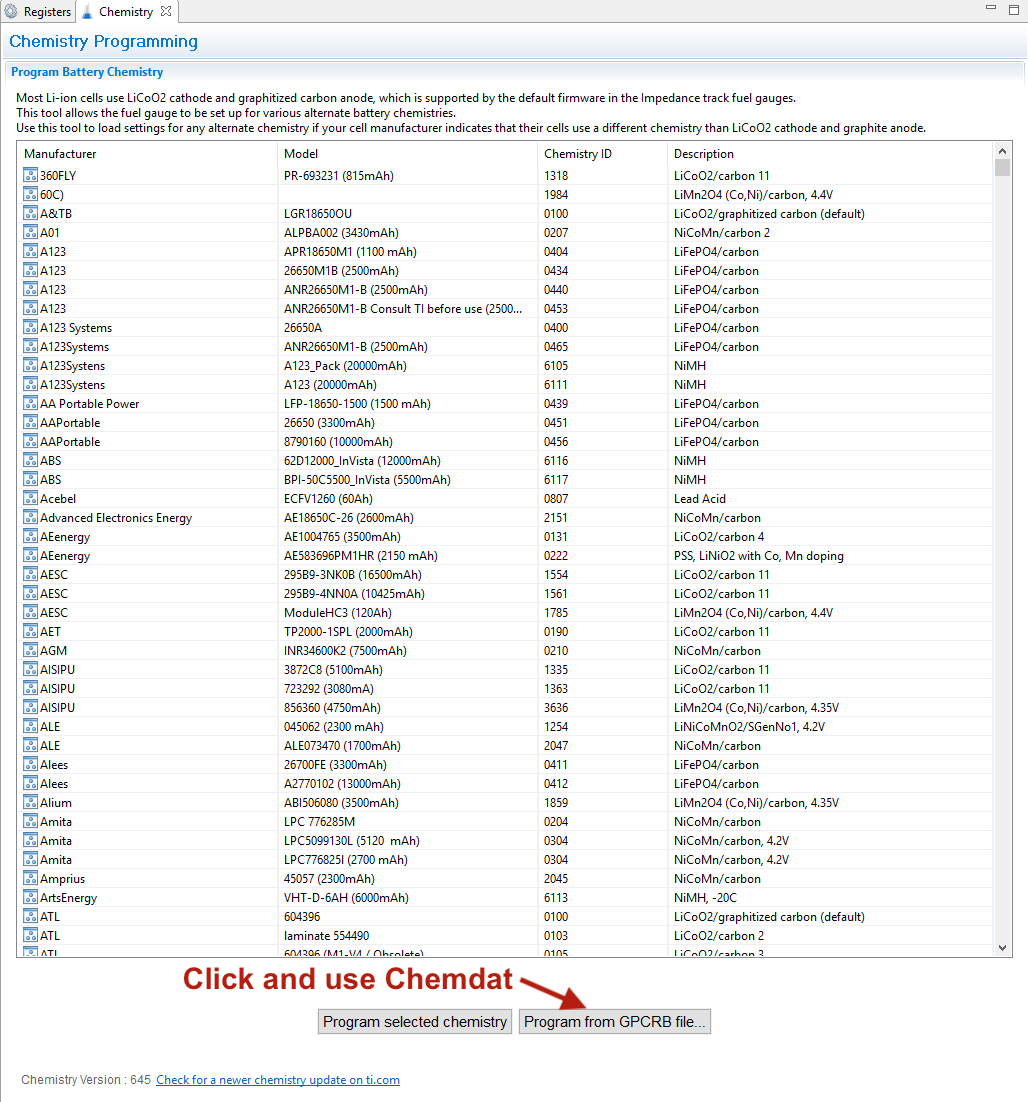

| Thank you for your interest in the Gauging Parameter Calculator from TI. There was an error in processing your report. The specific error encountered is: The following errors were reported by the calculation engine: Error: low temperature file has no rest after discharge current for OCVpoint is -0.006 Error: negative low temperature resistance observed, R=-19.4547168463698 usually caused by wrong chem ID selection 0 Please see the Gauging Parameter Calculator for information about the file format and the procedure for creating the input zip file. Should you want to resubmit or need assistance with the Gauging Parameter Calculator, please reference the sites below: • Go to Gauging Parameter Calculator to re-submit.

• Visit TI E2E™ Community on Battery Fuel Gauges or the Gauging Parameter Calculator. • TI Battery Management Homepage Thank you for using TI's Gauging Parameter Calculator for Battery Fuel Gauges. |

I had uploaded the following files config.txt • roomtemp.csv • lowtemp.csv • gg.csv on the link http://www.ti.com/tool/GPCRB

with rest period after discharge (in cold)?

wrjhygwejgrjwgerjgw e hgrjgwejgrhjwww.ti.com/.../GPCRBsdsdsfrtrwetrethewrwe

|

Your Gauging Parameter Calculator report is here.

|

|

|

|

|

|

Thank you for your interest in the Gauging Parameter Calculator from TI.

There was an error in processing your report. The specific error encountered is: The following errors were reported by the calculation engine: Error: low temperature file has no rest after discharge current for OCVpoint is -0.006 Error: negative low temperature resistance observed, R=-19.4547168463698 usually caused by wrong chem ID selection 0 Please see the Gauging Parameter Calculator for information about the file format and the procedure for creating the input zip file. Should you want to resubmit or need assistance with the Gauging Parameter Calculator, please reference the sites below: • Go to Gauging Parameter Calculator to re-submit.

• Visit TI E2E™ Community on Battery Fuel Gauges or the Gauging Parameter Calculator. • TI Battery Management Homepage Thank you for using TI's Gauging Parameter Calculator for Battery Fuel Gauges. |