Other Parts Discussed in Thread: BQEVSW, BQSTUDIO

We just went into production with a fuel gauge board that uses the bq34z100-G1 chip. The battery we are pairing the fuel gauge with is a 7.5 Ah 4S LiFePO4 pack.

The first batch that we built was 9 batteries. Our procedure is to program, calibrate, and test the fuel gauge boards, then pair them with the battery packs. The packs get fully cycled twice and then we retest the fuel gauge boards in a fully discharged state. All batteries passed and they were sealed up into their final housings (no longer can read ant info from the fuel gauge IC). The batteries are then charged to just under 30% before they move from production to stock/shipping. The batteries sat for several days but the next time they were checked the SOC had jumped to above 50%. This happened on 8 of the 9 batteries. Unfortunately theses packs with their gauges are fully sealed and i can not read any detailed information from the bq34z100-G1.

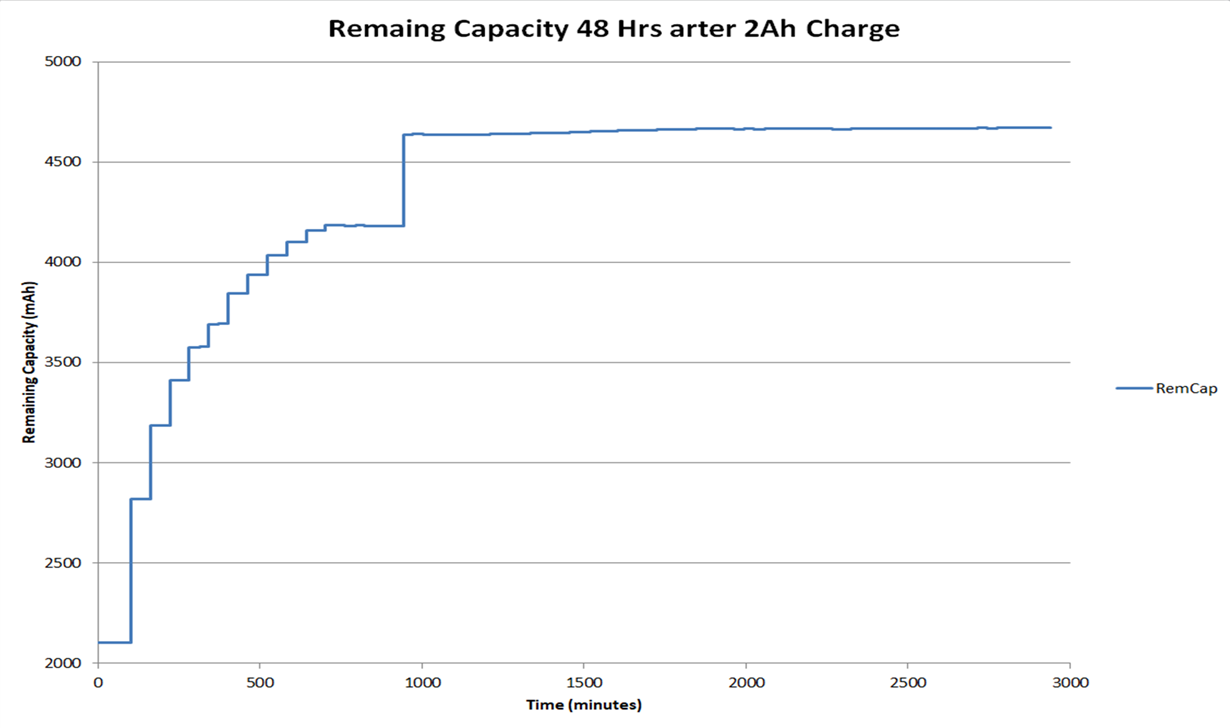

I have since brought through a larger batch of 20 fuel gauge boards. Some boards have demonstrated the same jump, from 27-30% to 50-60%. I have not been able to construct the circumstances under which this jump will always occur and have not been able to collect logged data on a battery capturing the jump or transition. I have confirmed that it is the remaining capacity that jumps while the FCC stays virtually the same.

Under what circumstances can Remaining Capacity jump while the pack is relaxing? I should note that sometimes the jump happens almost immediately after coming off of the 30% charge and sometimes it has taken 1-2 days. The inconsistency of the problem has made it especially difficult to narrow down or capture.

What information would help in diagnosing the underlying problem.

Thanks,

Matt