Hi,

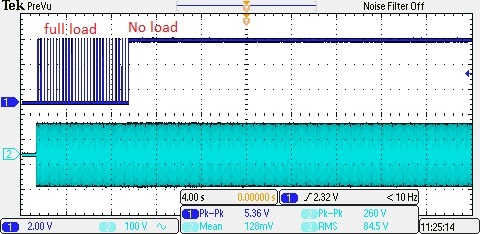

Recently I received UCC28740EVM-525 10 W Constant-Voltage demo board. It can't start up with full load in low temperature (-25 degrees).

I tried several methods: increasing Vdd capacitor, or input/output capacitor, removing NTC...etc.

It can start up with no load and half load,but it still has the cold-start problem with full load.

Is UCC28740 have some restrictions when operating in the low temperature?

Thanks for help.