We use the LM3409 to design a constant current source. For our application, a low ripple on ILED is important.

For evaluation we used a modified EvalBrd AN-1954 LM3409.

This setup achieved all the specifications, we made for our constant current supply. So I designed PCB and tried to make a Layout as

similar as possible.

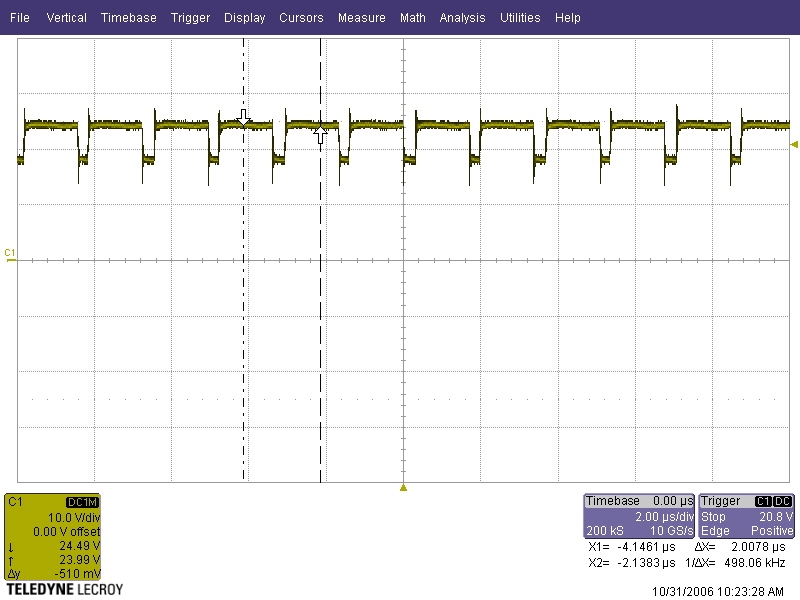

We did the same measurements with our own PCB and the ripple of ILED is up to factor 10 higher. Also the switching behavior at PGATE is absolute different.

Below I attached the test report of the EvalBrd and the comparison between EvalBrd and our PCB.

Test report EvalBrd:

Comparison:

Schematic LED-Driver:

Schematic Over- and reverse-voltage protection:

best regards

Benjamin