Other Parts Discussed in Thread: TPS92515,

I've been investigating using four LM3409s to use as an LED driver for an LEDEngin LZP RGBW LED.

One of the things I care about is high contrast, ideally aiming to switch the LEDs on and off fast enough that I can squeeze in 16-bit resolution per color, while maintaining a PWM frequency high enough that it's invisible. Usually I do this with a custom linear driver, but I'm intrigued by the shunt FET design for higher speed dimming.

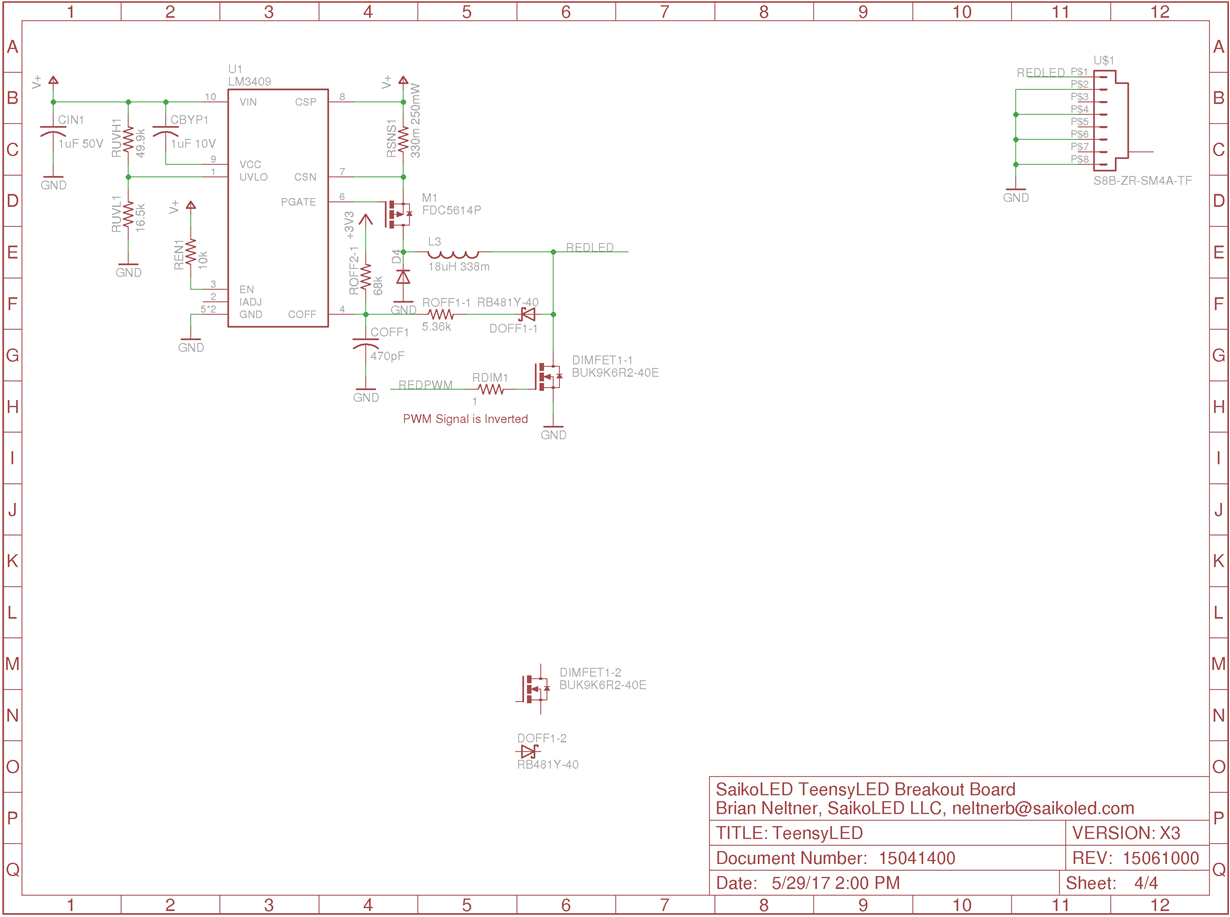

To ground the design in some numbers, I'm planning to use a FDMD82100L dimFET with 3.3V gate voltage supplied directly from a Teensy 3.2. I plan to use a 550Hz external PWM with a minimum pulse size of 27ns to get 16-bit resolution at the optimized PWM output speed of the Teensy 3.2 controller chip. I will invert the PWM signal in software.

The LED current per channel is 700mA, the Roff is calculated to be 5.36k, the inductor is 18uH, Vin is 30V, and Rds(on) at 3.3V Vgs is about 23mohm. Coff is 480pF.

Design Notes:

I started with the datasheet design, which adds a resistor Roff2 from COFF to Vdd to keep enough current flowing into COFF to keep the system on (so I gather) at a minimum level. I calculated 1.25Mohm for that resistor. Assume diodes from all sources into the summing junction at COFF.

This seems to match R11 in the evaluation board datasheet, but R11 is noload and no mention of it is given in the evaluation board datasheet other than it being there so I am not sure if I am misinterpreting. R11 is also connected to Vin rather than Vdd.

Question: Is R11 from the evaluation board datasheet identical to Roff2 from the datasheet? Should it be connected to Vdd or Vin? Or does it not matter as long as I calculate it accordingly using Roff1*V / I_led * Rds(on)? Or should it be left unloaded for some reason?

In the evaluation board datasheet, Figure 4 shows the EN pin should be coupled to the PWM signal voltage with C9 and connected to Vdd with R4.

I get that R4 is the pullup for EN so I'm reading this as only being relevant if the PWM pulse is turned off, which will allow it to briefly shut off EN.

Question: Is coupling the PWM signal to the EN pin like this helpful? What is the point? It looks to me like it just causes EN to show the external PWM signal if it's a short pulse. Doesn't that defeat the point of the dimFET? Shouldn't EN just be tied to 3.3V to keep it active at all times when using the dimFET?

And then in the evaluation board datasheet, Figure 5 is explained as necessary if your PWM frequency is below 10kHz, which I definitely am. This is described as necessary because otherwise Coff falls too low as the voltage from Vo drops to zero and the capacitor discharges, so provides 3.3V through Roff2 when the dimFET is active to keep the off time from being too low. My calculation is that this resistor should be under 130 ohms.

Question: Did I calculate Roff2 (evaluation board datasheet, Figure 5) right? It seems weird that the value of Roff2 is independent of the PWM voltage given that it is connected to the PWM signal. It is also weird that none of the Roff paired diode forward voltages (the one from Vo, the one from PWM drive, and the one from Vdd/Vin) are relevant in calculating these values.

I think if I can understand these three questions, I can probably work out the rest.

What would you recommend doing for this application? Is this the right chip for the job?

References:

Part Datasheet - http://www.ti.com/lit/ds/symlink/lm3409.pdf