I have got yet another question.

Is it possible to alter the application from a constant current to a constant voltage mode? The reason why I'm asking is, we want to use about 138 LEDs in our product: 46 strings with 3 LEDs per string. Failure of one LED would result in the current increase in the remaining strings. This is undesirable for 2 reasons: 1) failure of an LED would put more stress on remaining strings, 2) input current of the driver would remain unchanged until the last string works. In our application the current drop is used to let the "external world" know there is something wrong with the light.

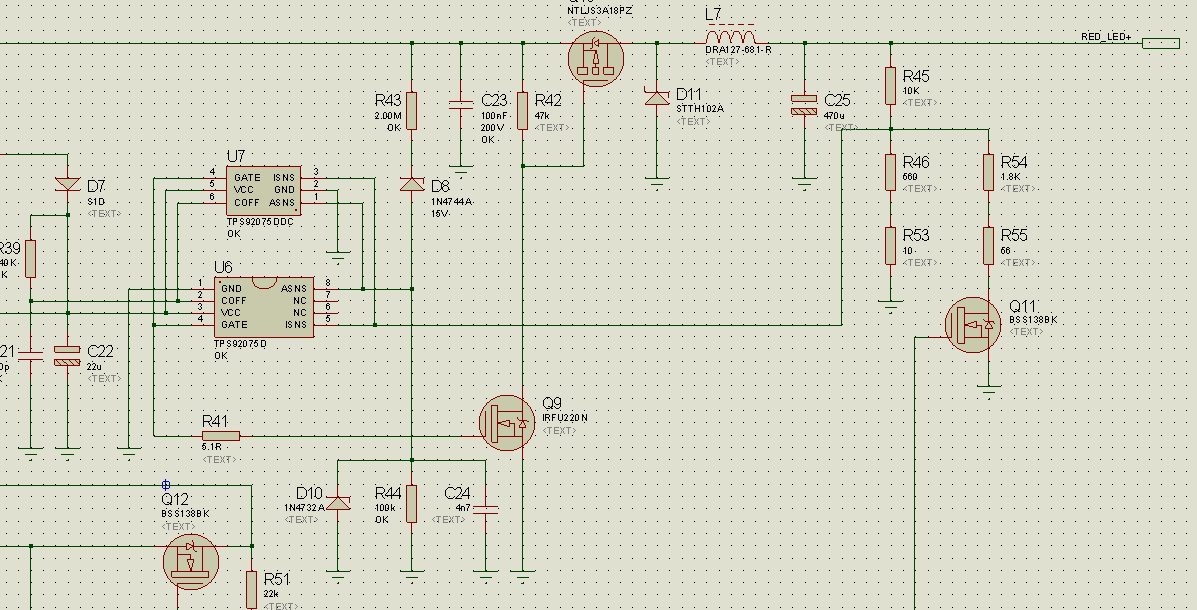

Below I attached an altered diagram of the driver. Please disregard values, as they have not been calculated yet. Mys question is about the topology that was changed to maintain constant voltage at the output (RED_LED+). Would this work?

Thanks.