Hi Team,

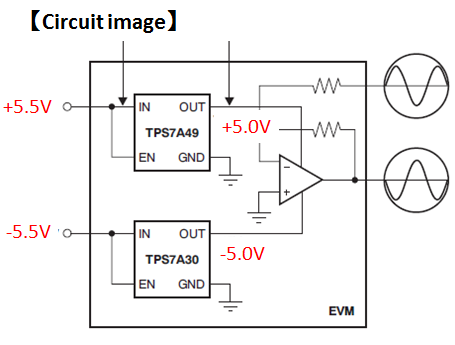

Our customer are evaluating TPS7A4901 & TPS7A3001 at the following condition.

However, the click noise occurs from the audio amp.

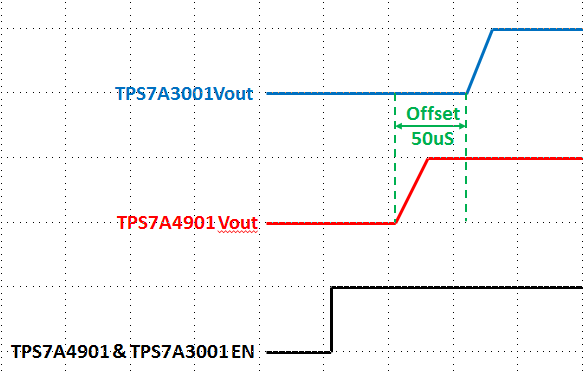

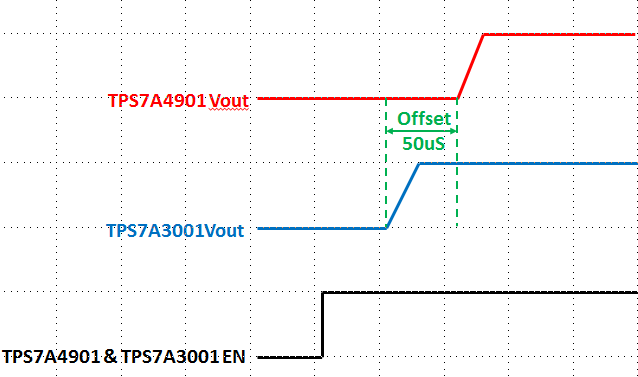

According to our customer, it is caused by the fact that TPS7A4901 and TPS7A3001 do not startup at the same time.

Therefore, they would like to know the method to solve this problem.

[conditions]

Vin=5.5V => TPS7A4901 => Vout=5.0V / Iout=150mA

Vin=-5.5V => TPS7A3001 => Vout=-5.0V / Iout=150mA

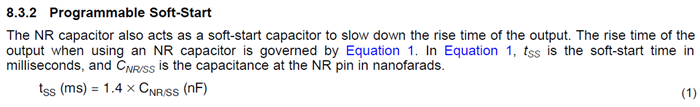

I’m understanding that we can change the startup time to change the soft start capacitor.

Could you please let us know if you have any idea?

And, have you received a similar question?

Could you please let us know if you have other recommended device?

Regards,

Kanemaru