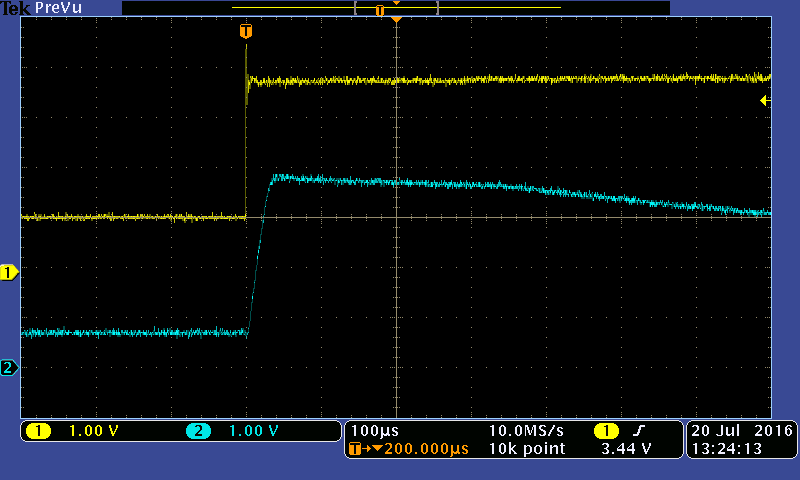

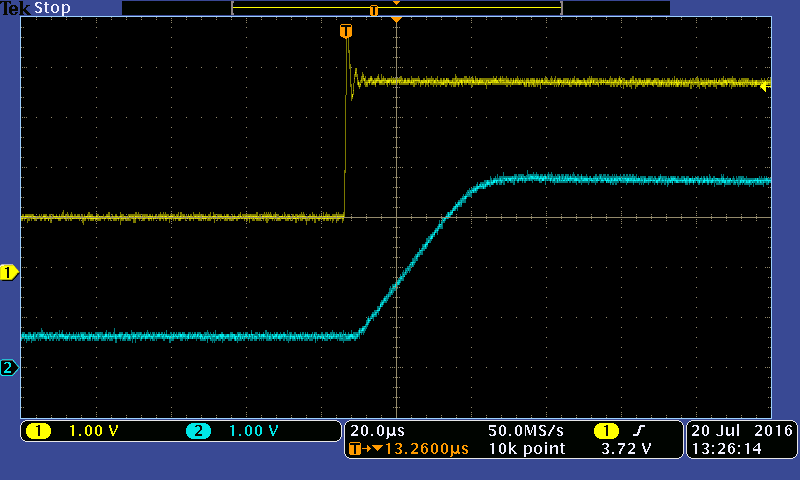

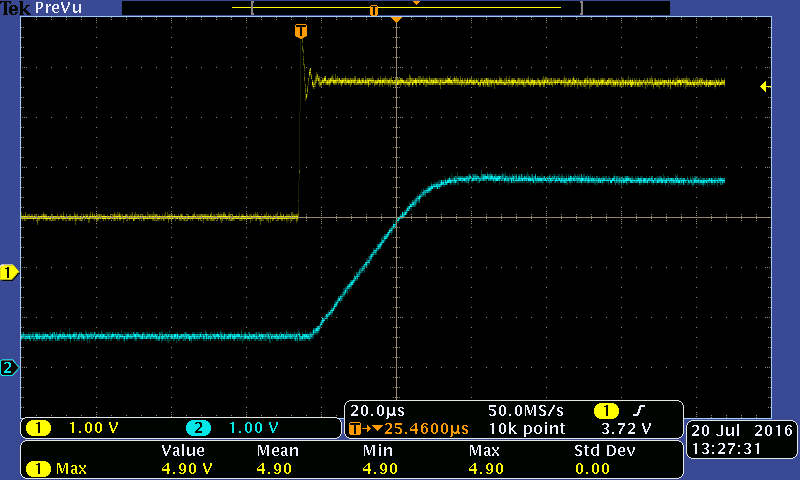

I have a TPS797285 in a Lion battery circuit powering a MSP430G2553 and 4 green LED. I have attached a schematic snippit, the LED are on P 2.1-2.4.

Input voltage is from a single 800mAh Lion cell. In this application the voltage range is 3.5V-4.2V

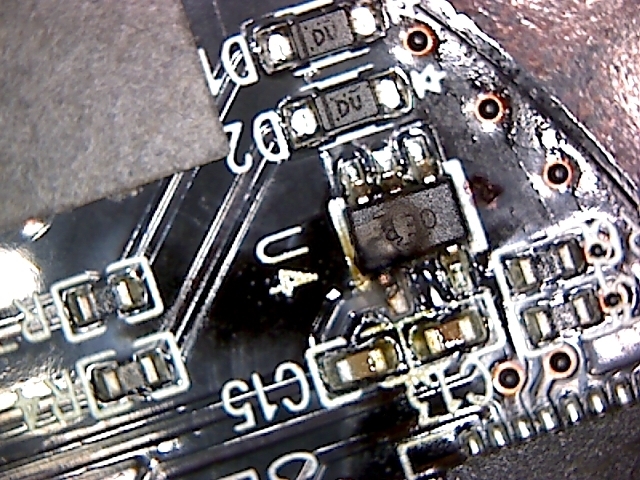

Each LED is set to draw about 8-10mA(led Vf is 2.4V max), and the processor should be drawing no more than 10mA and is asleep most of the time. in most cases I would think the current limit would kick in on this part before there was any kind of thermal issue. There is some package bulge and char.

Looking for some help with failure analysis. any help is appreciated.