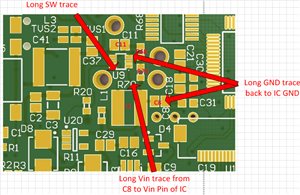

We have a 6 layer board with the TPS61220DCKT to produce 5 volts for sensor power, backlight power, and other

features. Our first design had no issues with the 5 volt power. We made a couple of modifications to the board and now

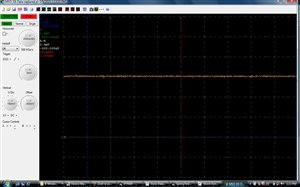

have severe power ripple, and low power voltage (about 4.5 volts).

I've put together a 3 page PDF (mostly pictures) to explain the problem I'm seeing.

It can be viewed as this file:

or at the link below: