Hi everyone

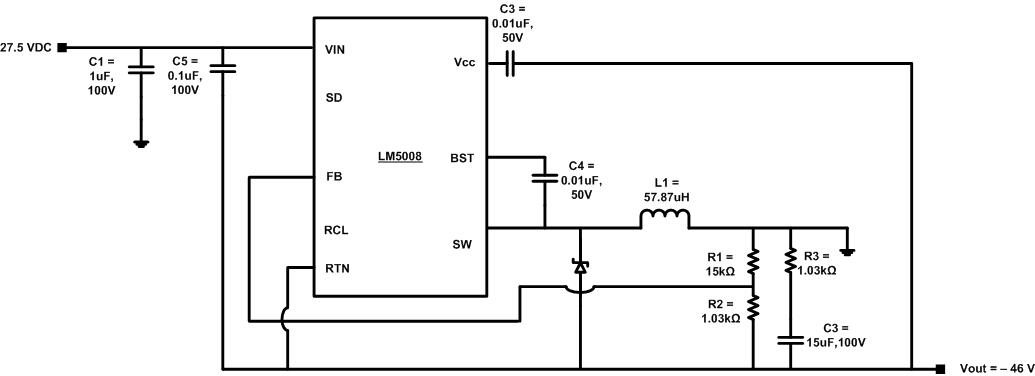

I need to design a negative power supply of -46V, 27mA from a positive voltage supply of 27.5V. I have posted here before and have been suggested to use LM5085 for inverting configuration, since I need a low current rated supply so I thought of using LM5005. I am having trouble deciding which configuration and formulas to follow for LM5005 since I could not find any note mentioning how an inverting configuration can be made from LM5005. I read slva317b as a reference for producing inverting power supply from a Step-Down regulator but I am not sure if all those formulas apply to LM5005 as well as the pinouts of both the chips are slightly different.. Can we use LM5005 in inverting configuration? What formulas and requirements are necessary to use it in this configuration

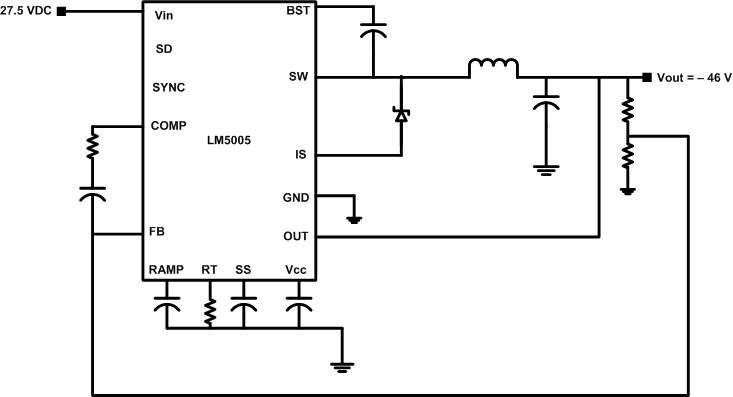

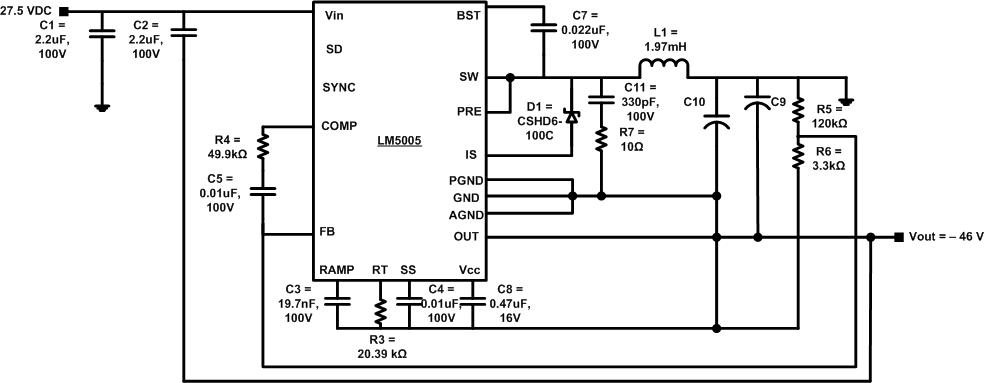

I extracted this schematic from LM5005 datasheet for using it in an inverting configuration. Do you think its going to work?