Hi All,

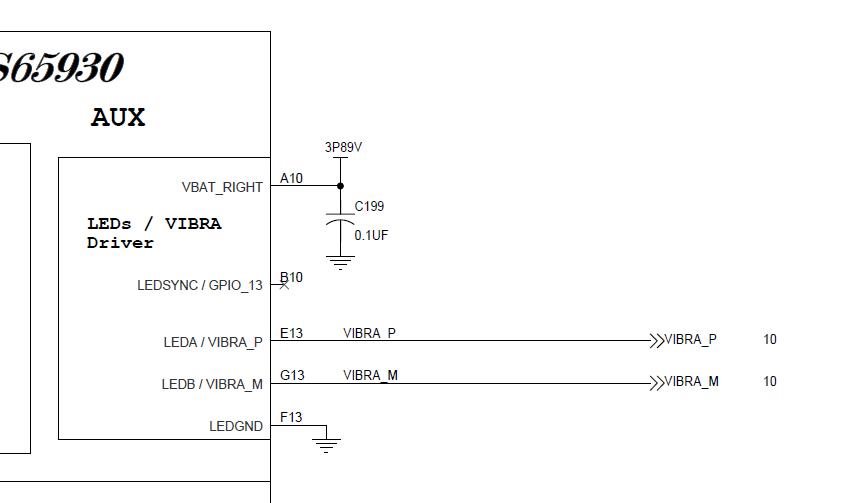

We are trying to control the output voltage of the VIBRA_P/VIBRA_N of the TPS65930 vibrator section through VIBRA_SET[7:0] register. I have a couple of questions.

1. The minimum differential output swing as specified in the Vibrator H-Bridge section of the TPS65930 datasheet is 3.6V, though the VBAT is only 2.8V. How does the TPS65930 achieve this? Please clarify,

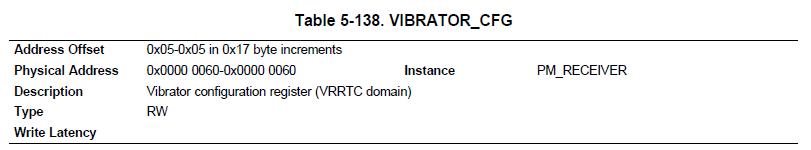

2. Currently, we are using a vibrator which can operate till 3.6V. As the existing vibrator is obsolete, we are forced to use a vibrator(Z3OC1T8219731) which can operate till 3.2V(We had to match the mechanical dimension as well. Hence the limitation). We are trying to change the Vibrator differential output voltage to match that of the vibrator. Changing the values of the VIBRA_SET[7:0] register is having no effect on the vibrator output voltage. The value of the VIBRA_CTL register is 0x01.

Please let us know if we are missing anything to make the VIBRA_SET[7:0] register changes to take effect.

Thanks & Regards,

Naveen