Tool/software: WEBENCH® Design Tools

Hi all, I have some troubles with LMZ14203 DC-DC Step-down converter.

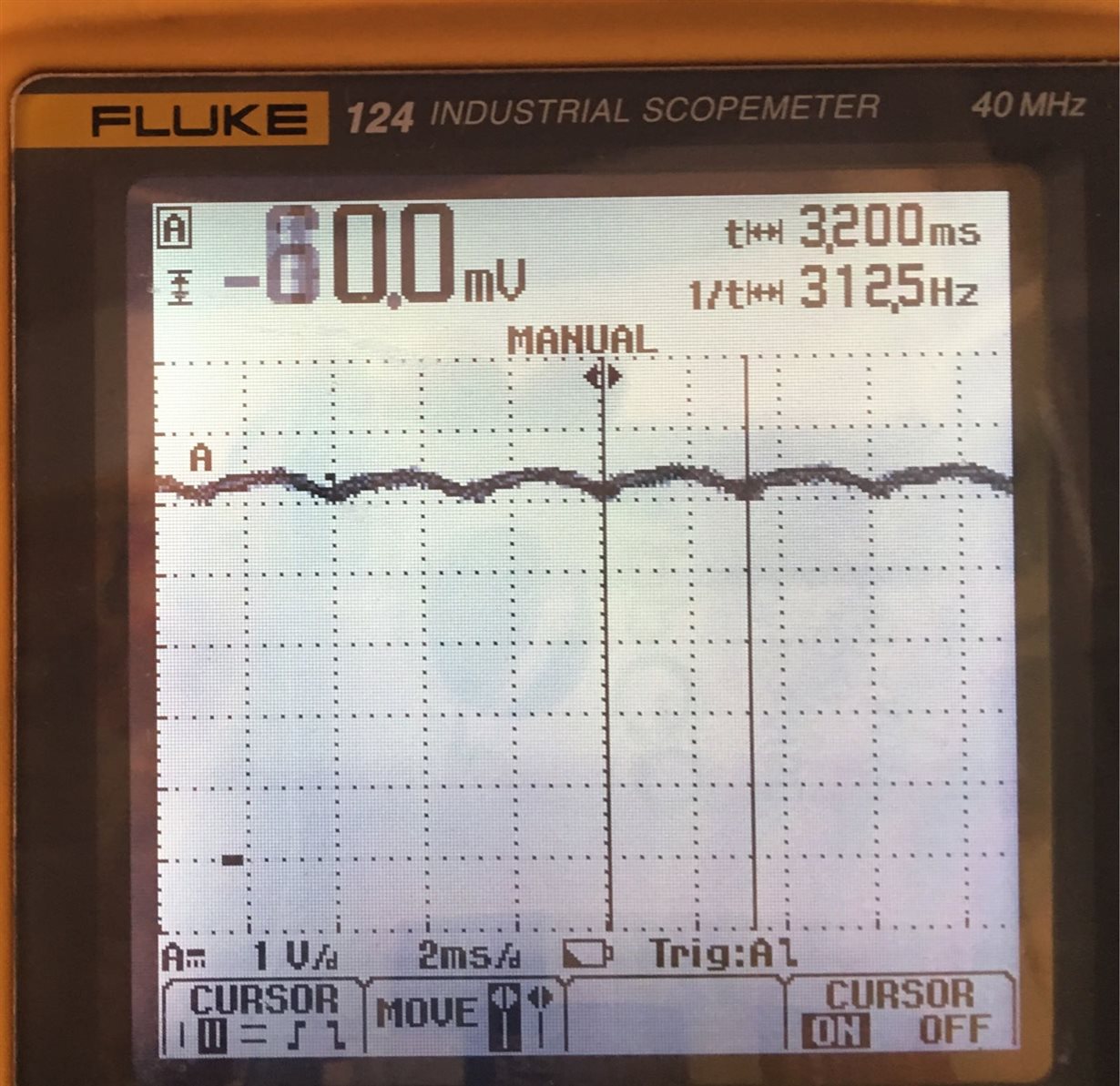

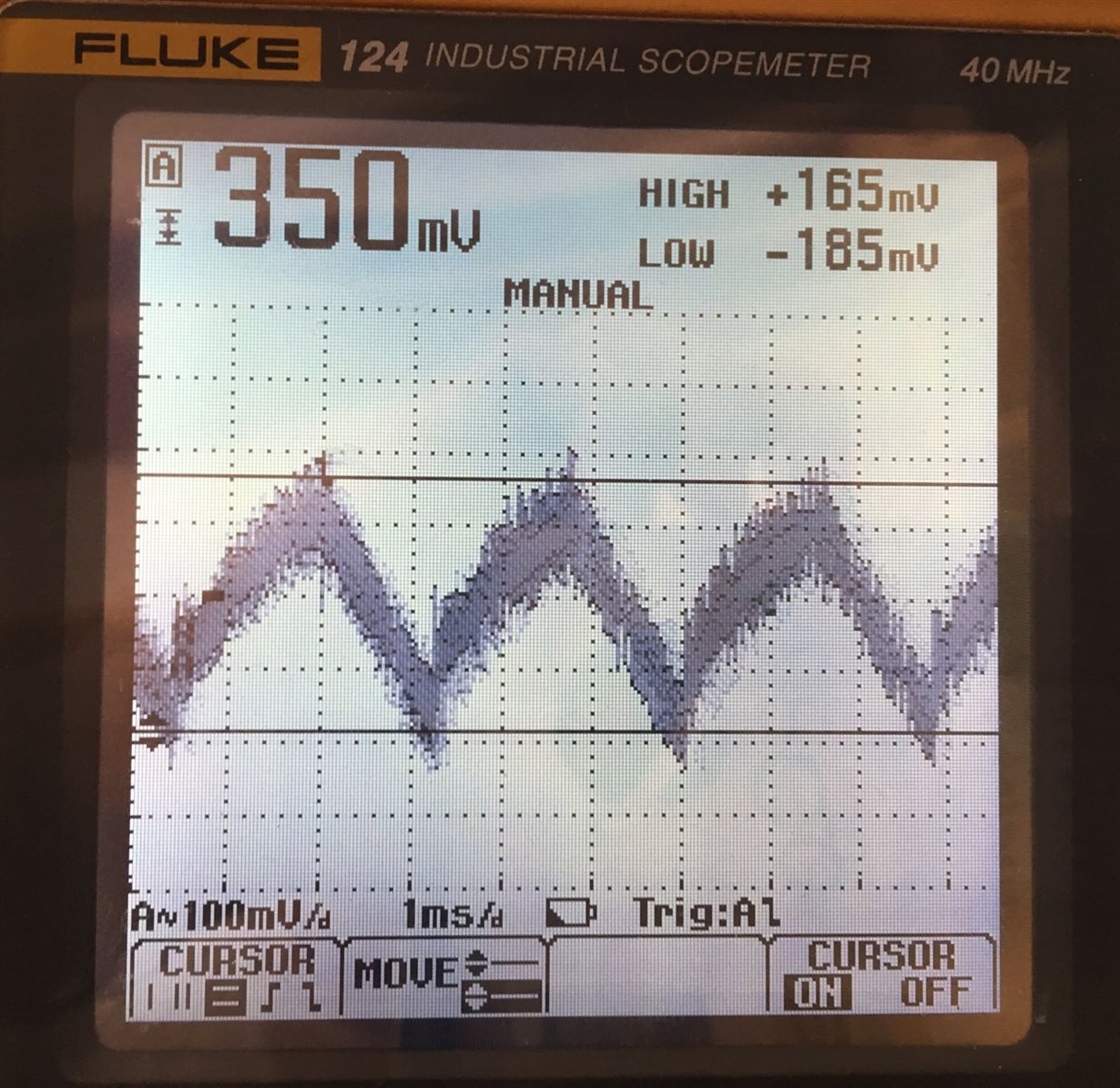

The Datasheet is declaring 8mVpp of ripple, while in reality I am measuring 340mV over my board.

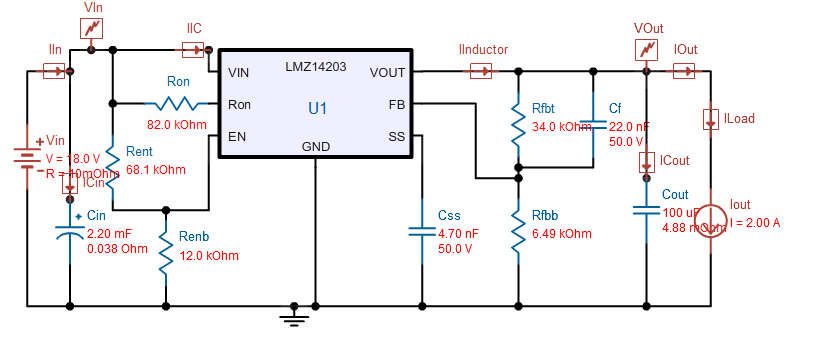

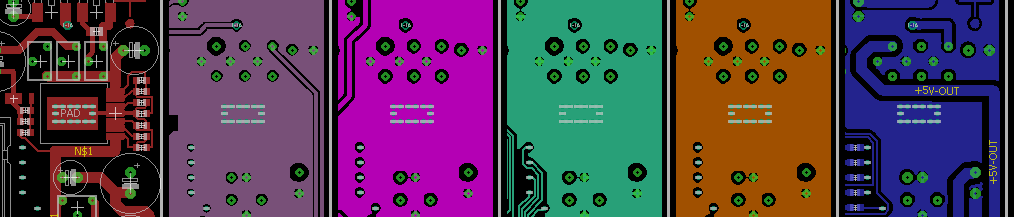

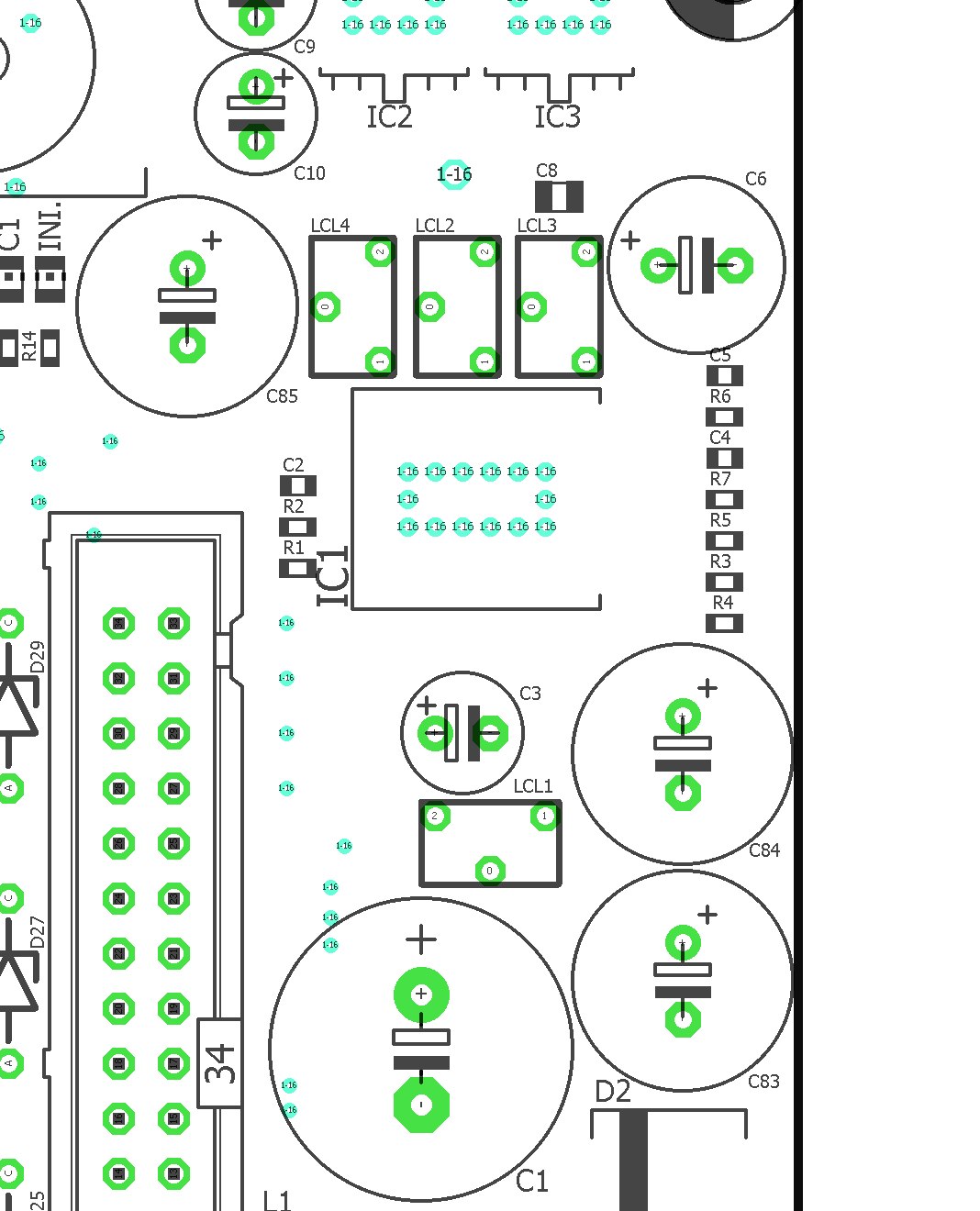

This is the WEBENCH proposal:

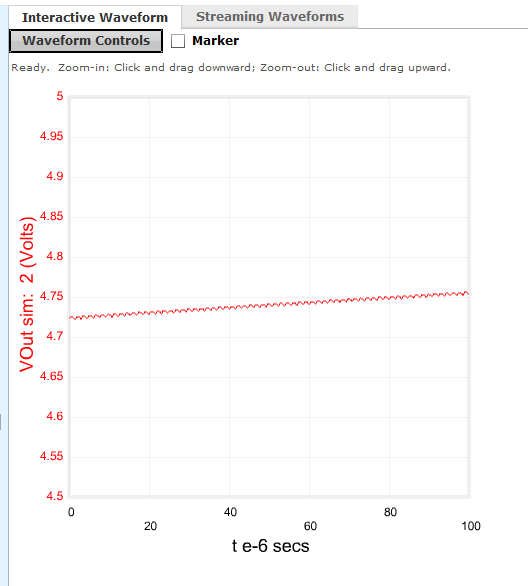

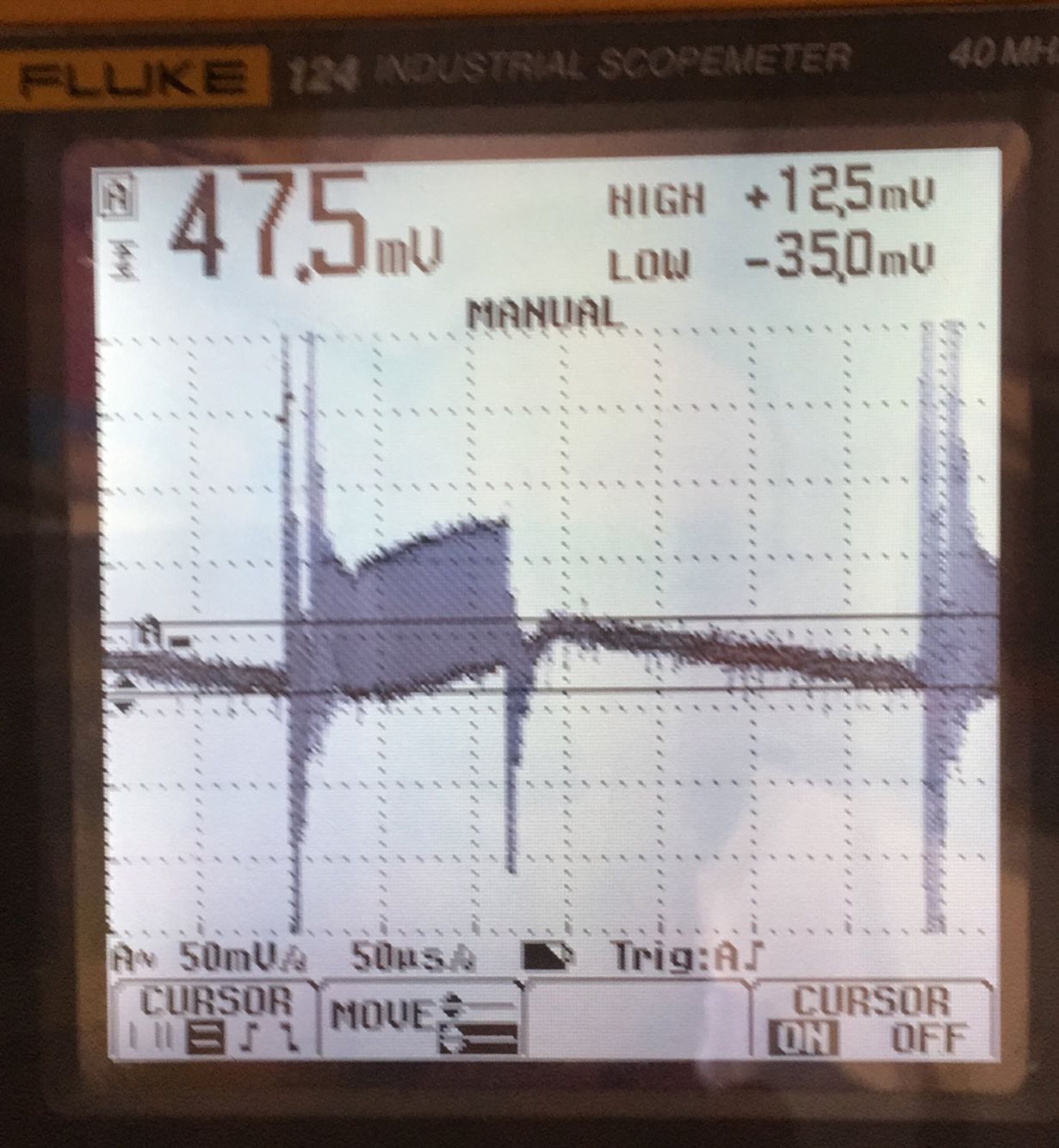

and this is the waveform from the simulator:

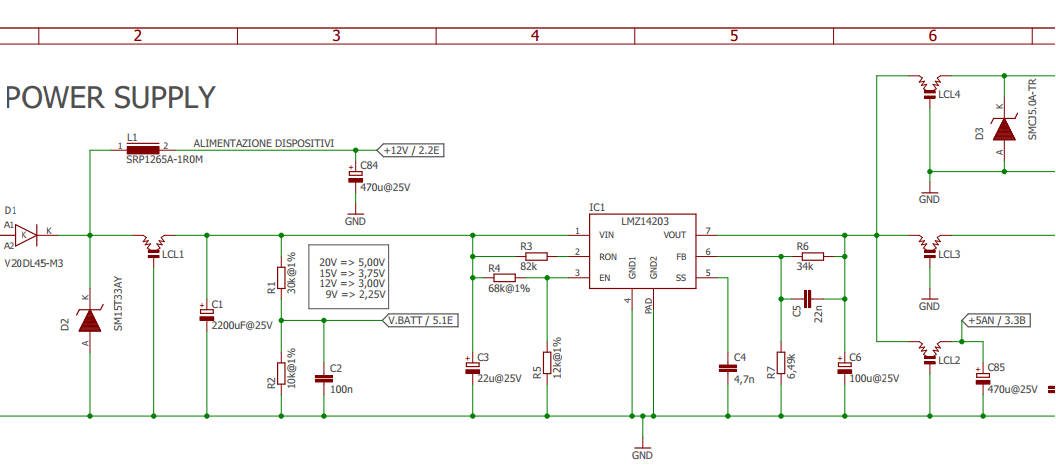

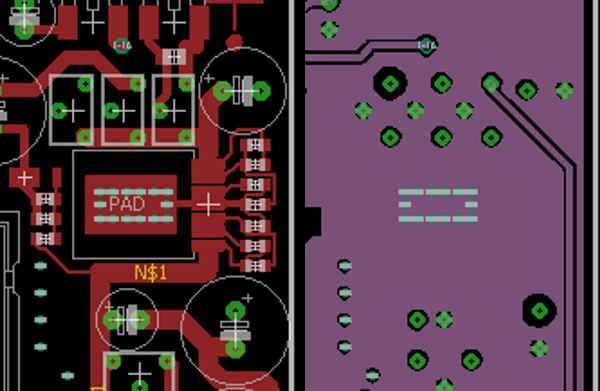

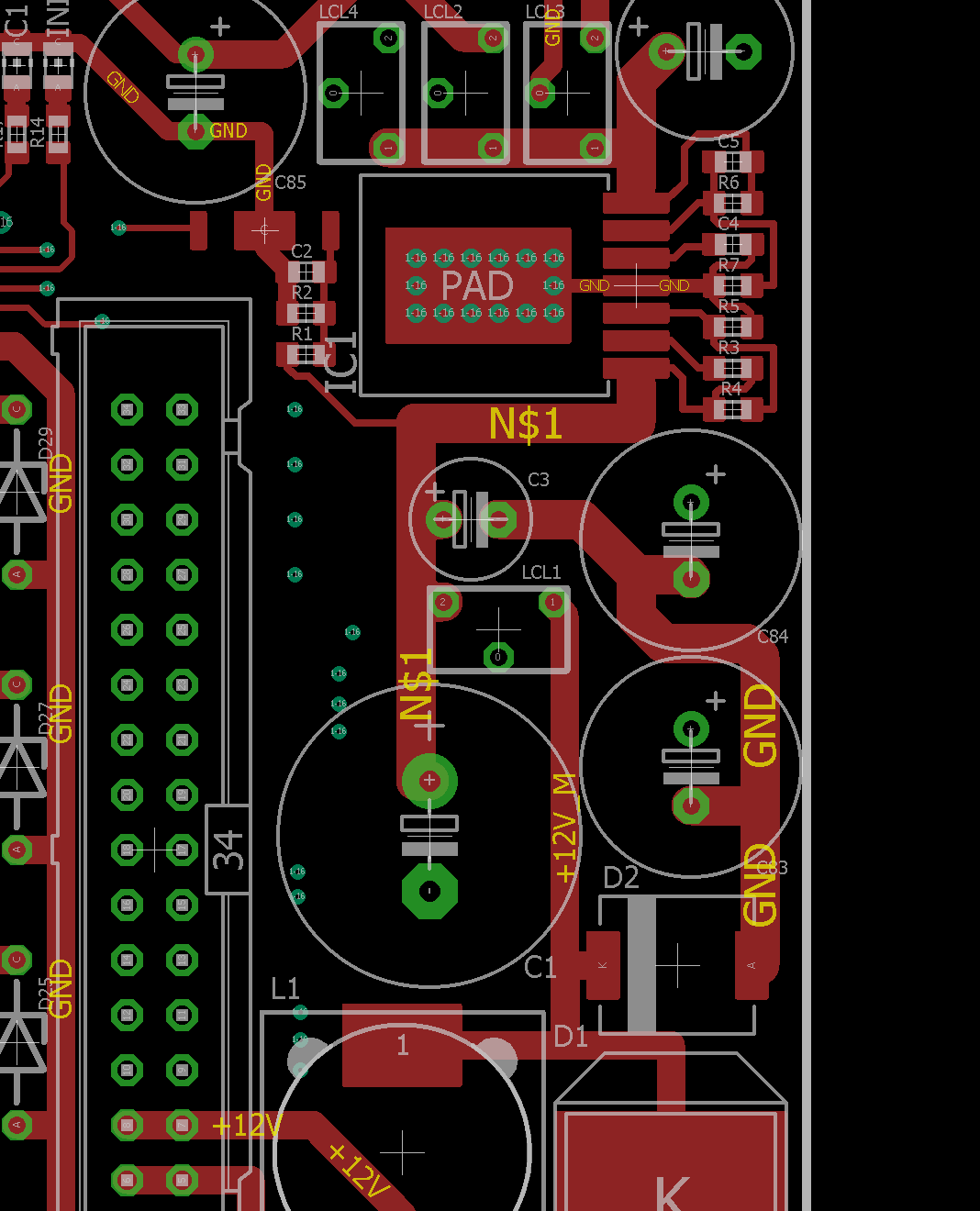

Now I show you the real schematic:

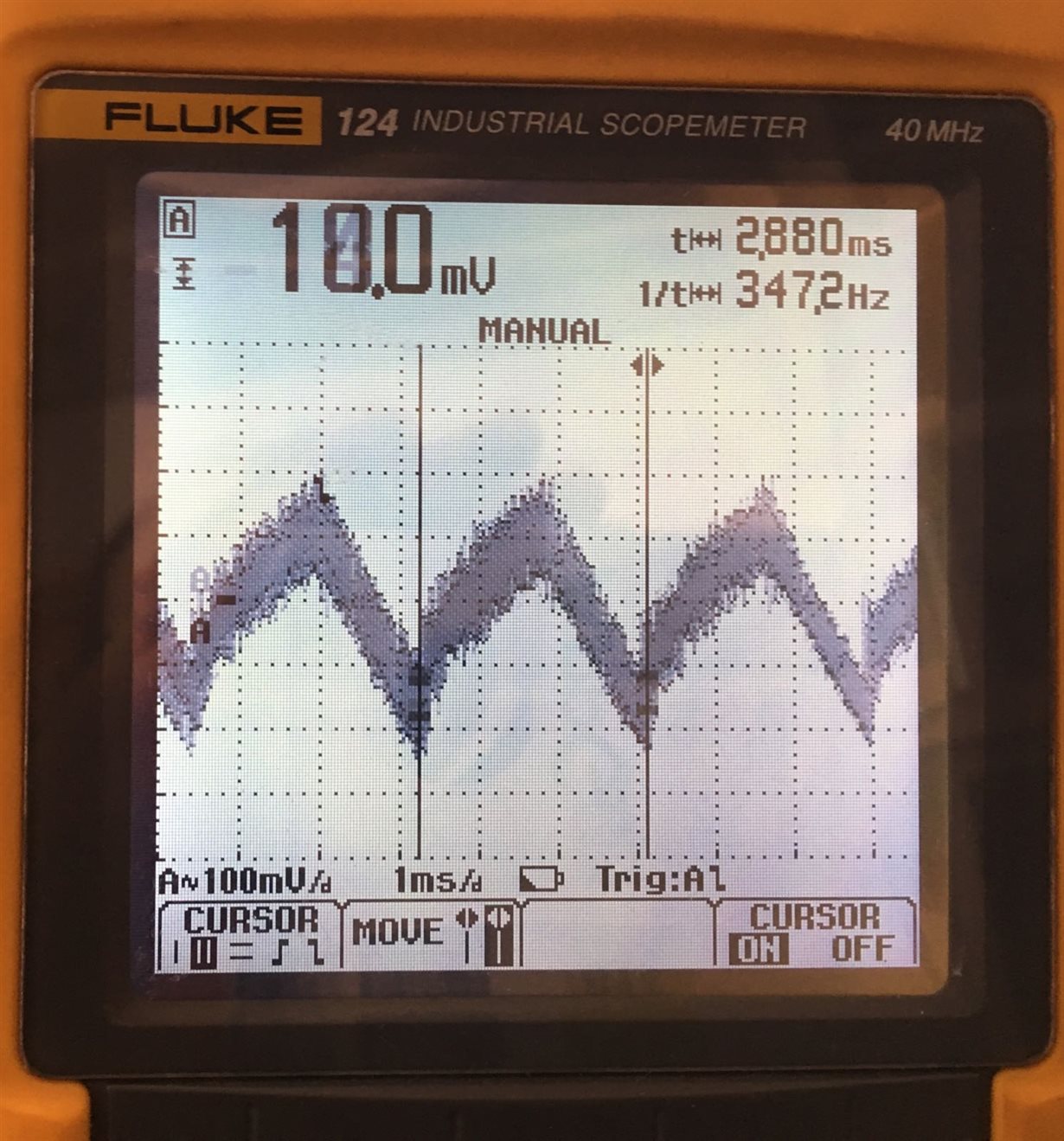

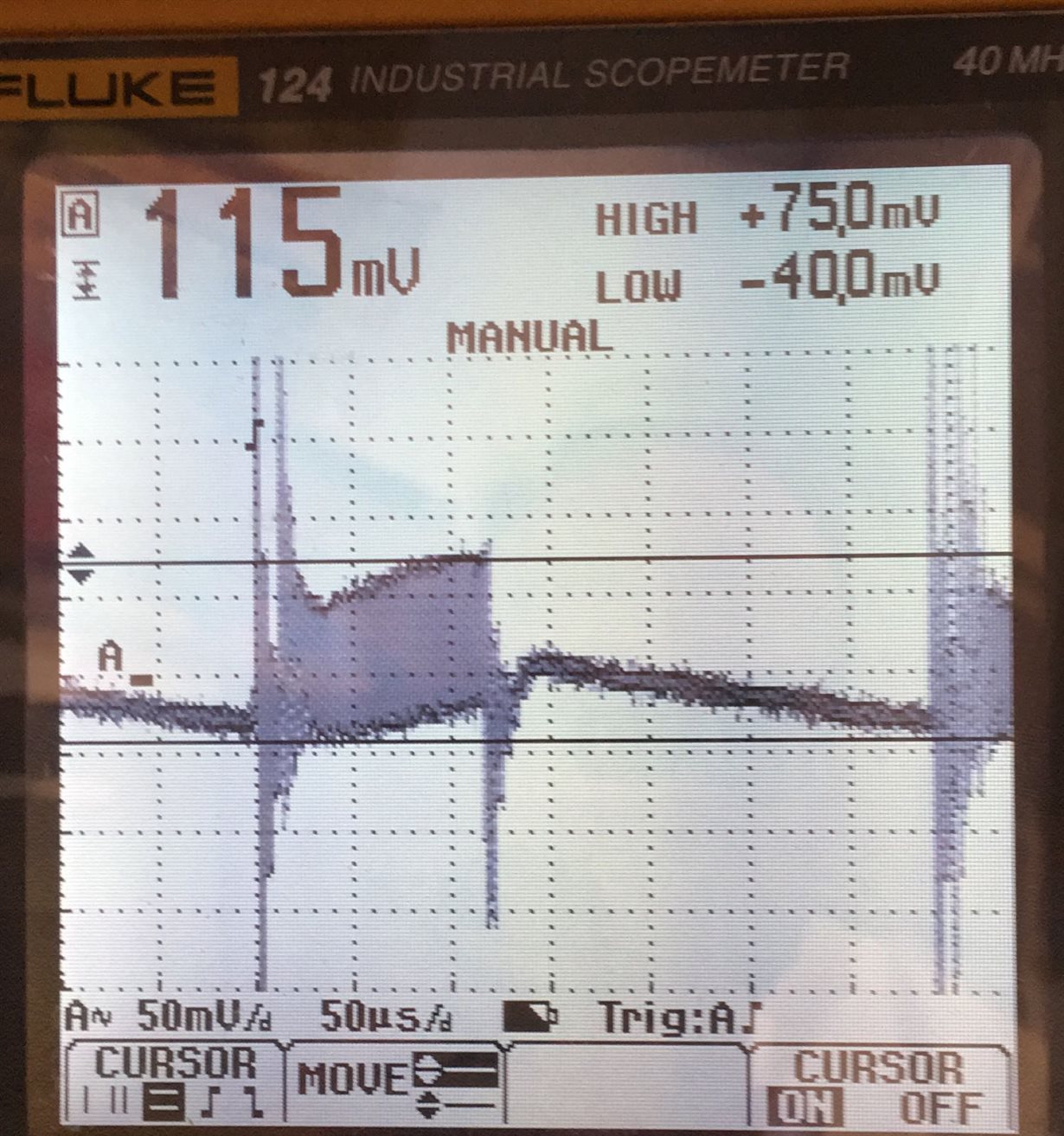

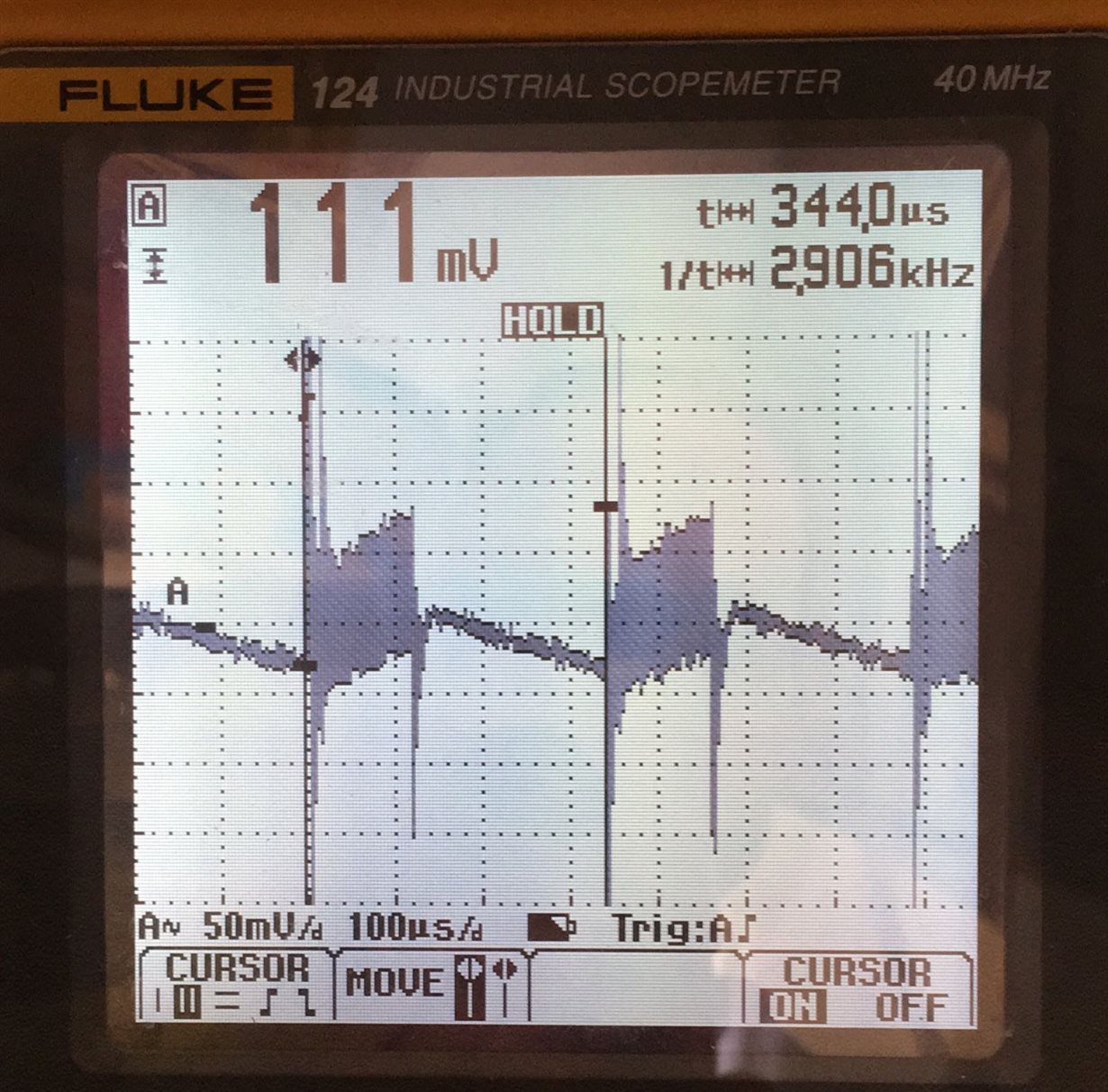

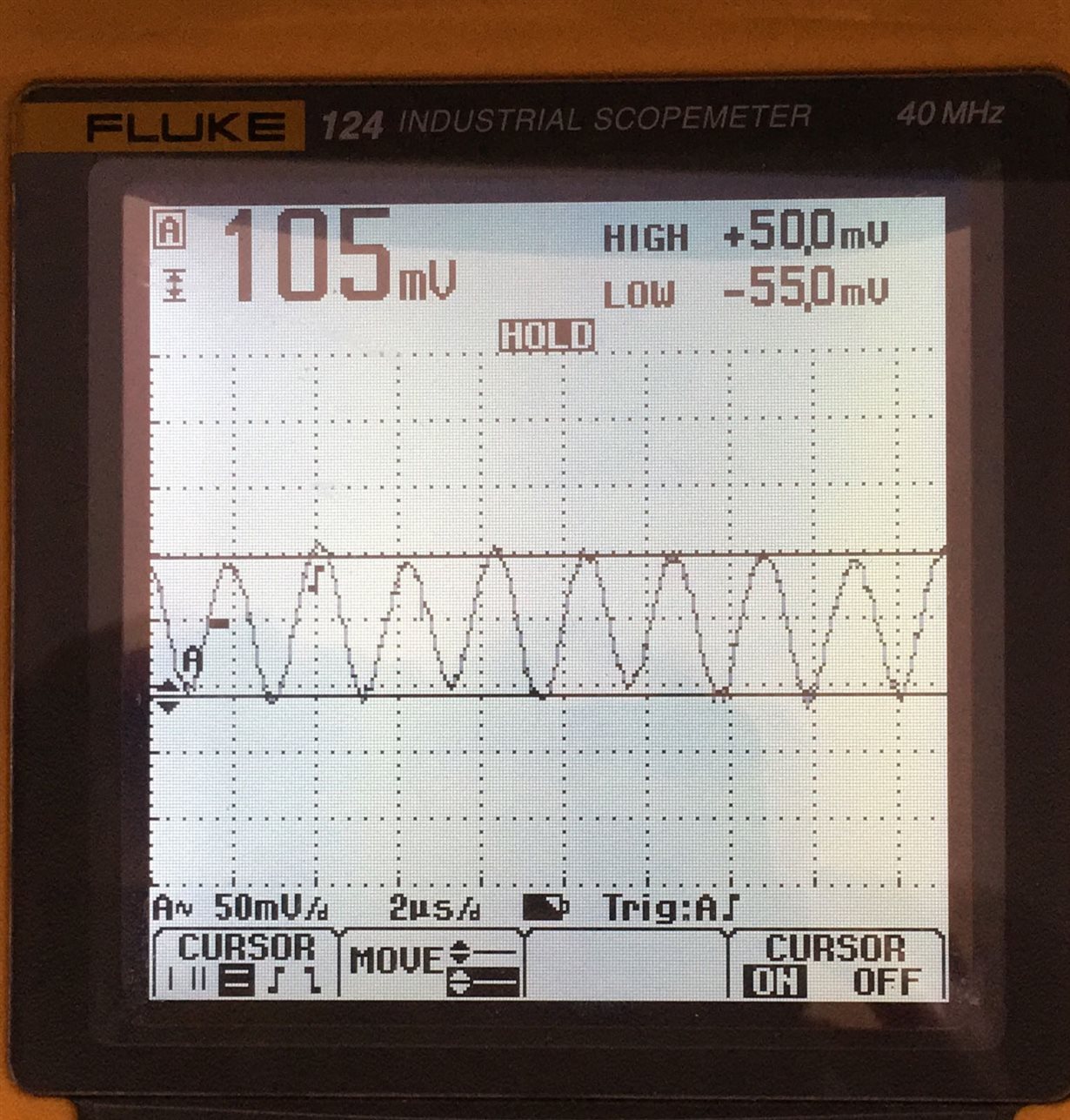

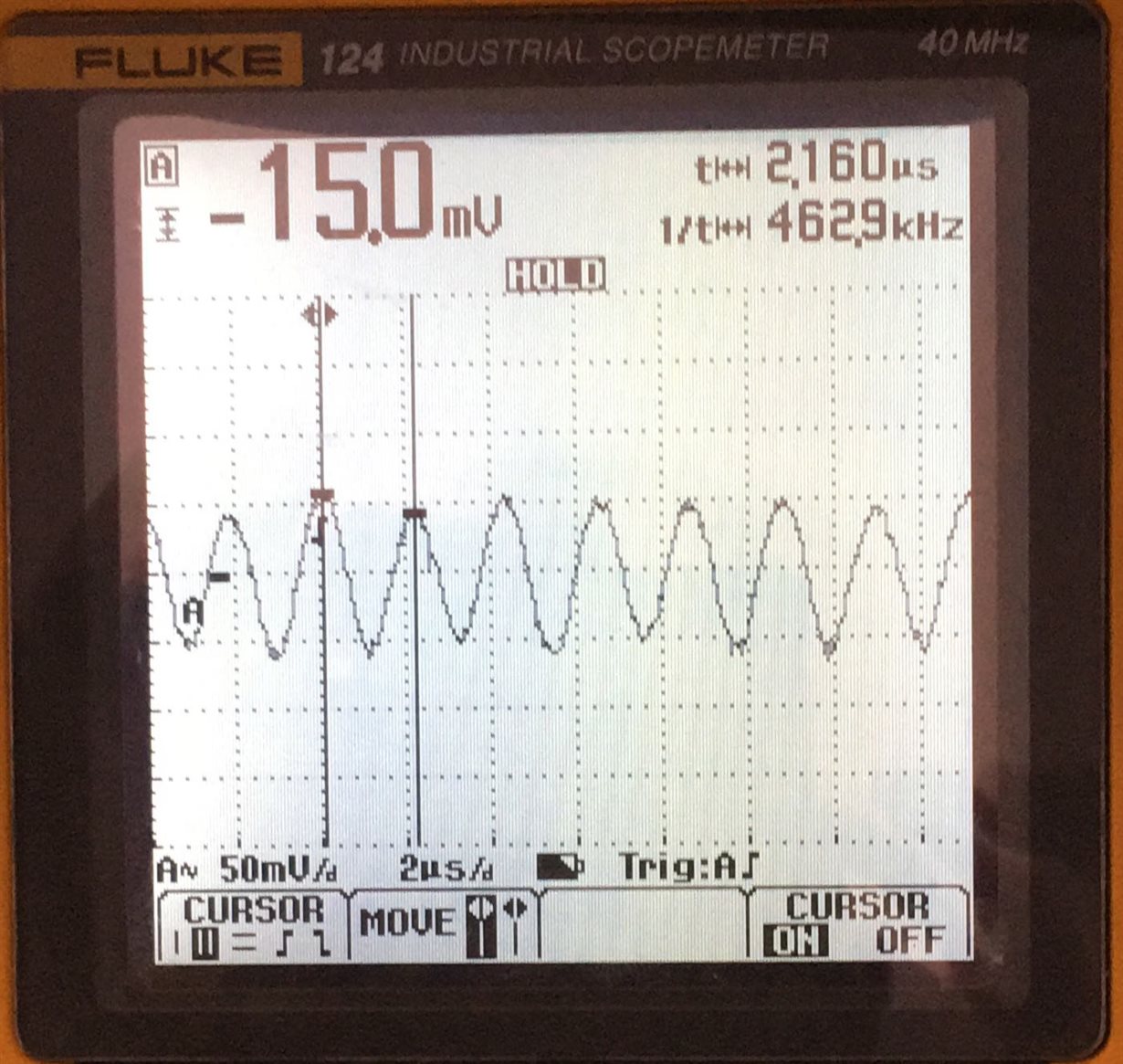

Ok, with this setup, I have the following waforms on the Oscilloscope: