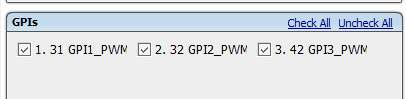

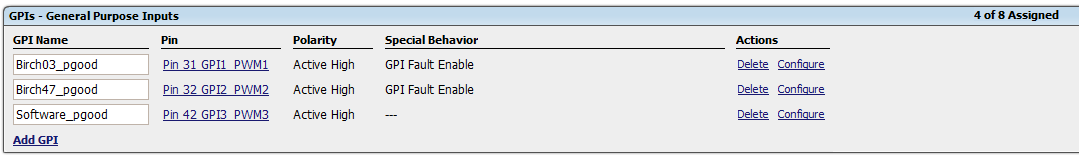

If I use three GPI pins to control the system reset,as below:

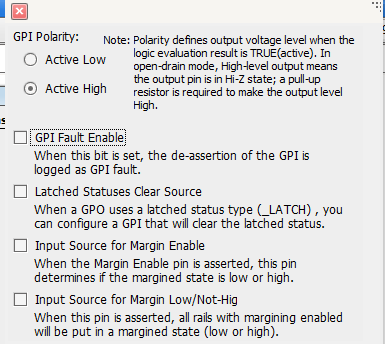

But one of the three GPIs, GPI3 only set Active High, doesn't set Special Behavior,as below

Then what will happen? Does only GPI1 and GPI2 control system reset and GPI3 can be ignored?Does GPI3 pin voltage have any influence on system reset?Can GPI3 be low voltage or floating?Or must be high voltage?