Other Parts Discussed in Thread: TPS2660

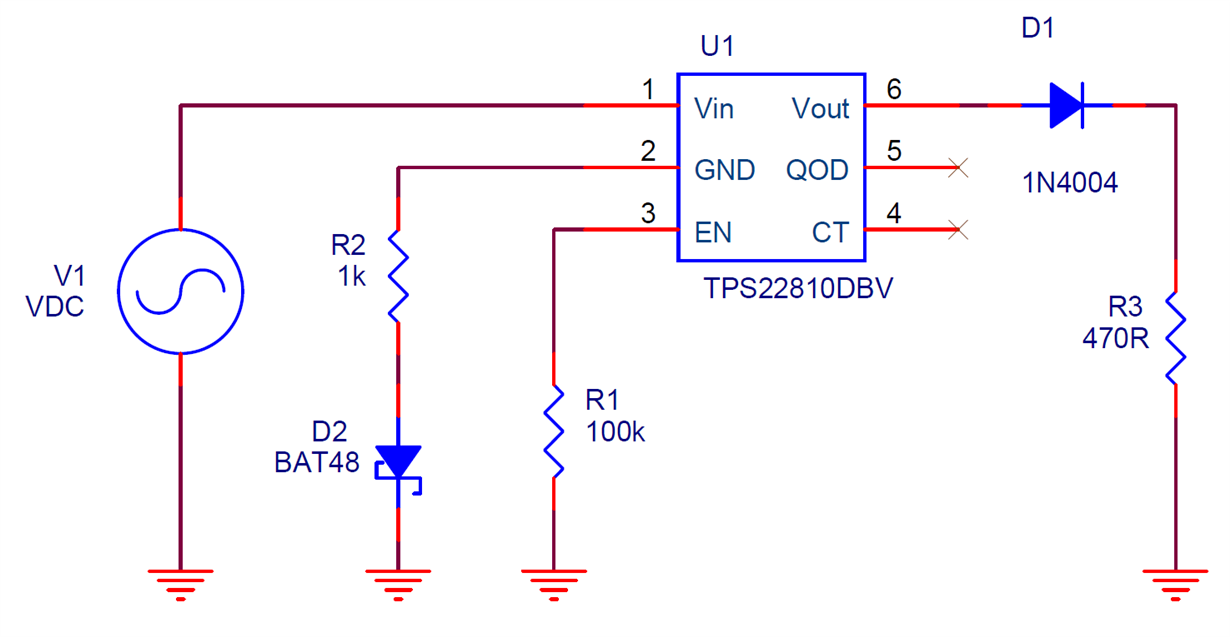

I have designed the TPS22810 into a circuit as a topside power switch. I believe I did not account for the possibility of my input being connected in reverse, though, and so I am trying to adjust my design accordingly.

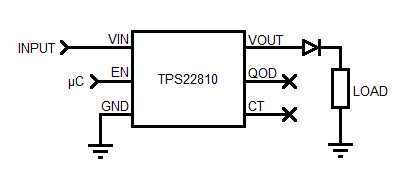

The circuit does not make use of the QOD or CT pins. A microcontroller controls the enable signal. The load that the switch controls is already protected from reverse currents. It looks as follows in the system:

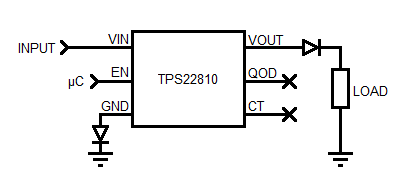

The input can go up to 17 V, and has the potential to be connected backwards for -17 V at the input. I would like to avoid putting a schottky diode inline with the input, since I really do want to avoid the additional losses. I have seen some parts that allow you to add reverse protection by putting a diode on the low side, and I was wondering if that would be sufficient for this part as well, especially in light of the fact that I don't get any reverse current from my load. What I'm proposing is this:

The diode on GND could be made a Schottky if necessary.

If an inline diode or MOSFET would be the only way to add reverse input protection to this part, I could use a suggestion of an alternate part that already includes the reverse protection. I'm extremely space limited, though, which is one reason I selected this part in the first place.