Other Parts Discussed in Thread: FDC2114

Hi Team,

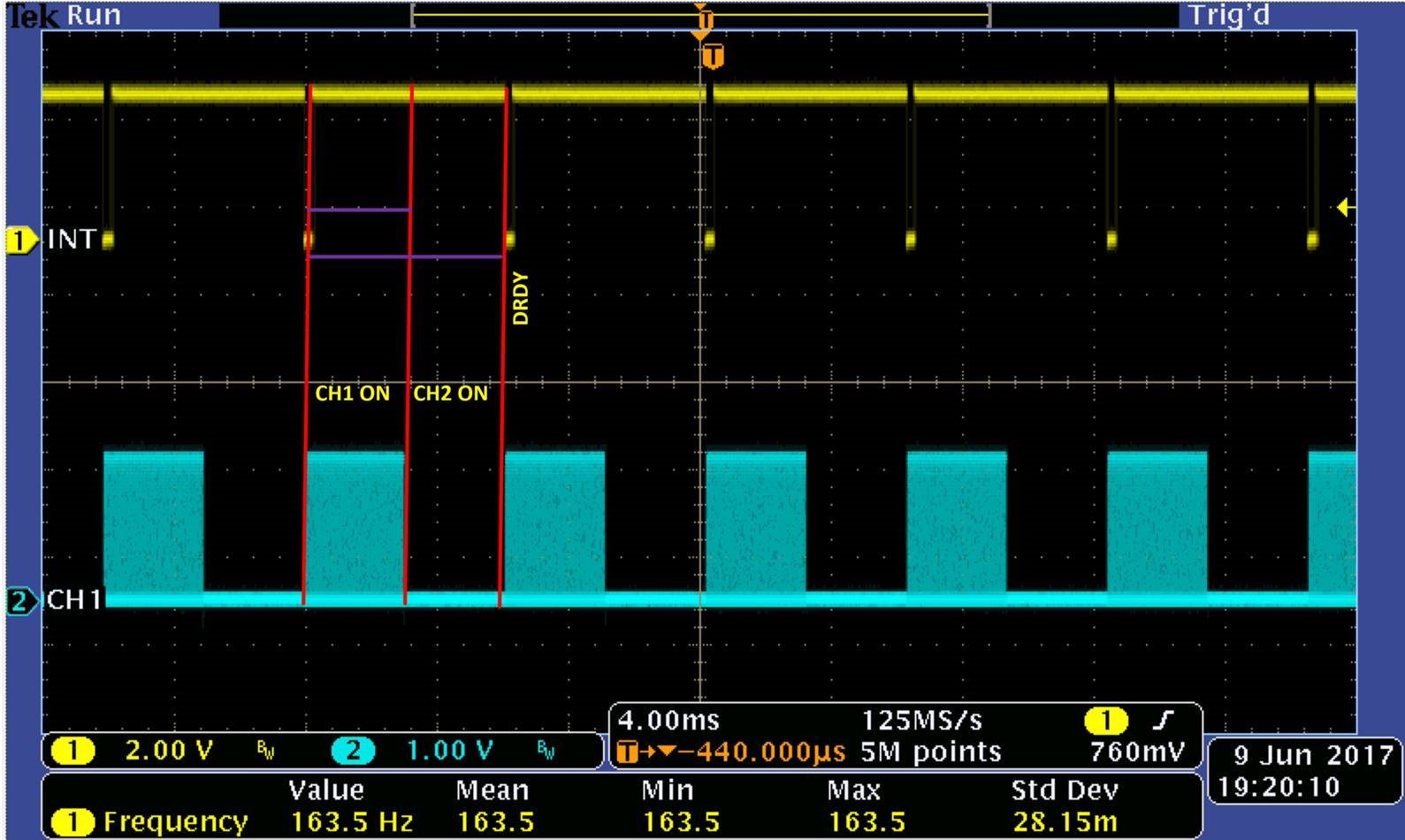

for my project I need to get at least 6000 SPS out of the FDC. I tried to use an Arduino Mini Pro 3,3V as well as an Raspberry Pi B+, but I never get close to this point, even if the theoretical maximum is 13,3kSPS.

I use 4,7kOhm Pullups and clock frequency is set to 400kHz.

On the Arduino, I measured the time which passed while filling an Array of 100 Samples: 244.000µs/100Samples --> 244µs/Sample --> 4098 SPS

On the Raspberry, I measured the time which passed while filling an list of 10.000 Samples: 8361704µs/10.000Samples --> 836µs/Sample --> 1196 SPS

Why is the Communication that slow, espeacially on the Raspberry which should have enough power to receive this amount of data? What am I missing?