Other Parts Discussed in Thread: FDC2214EVM

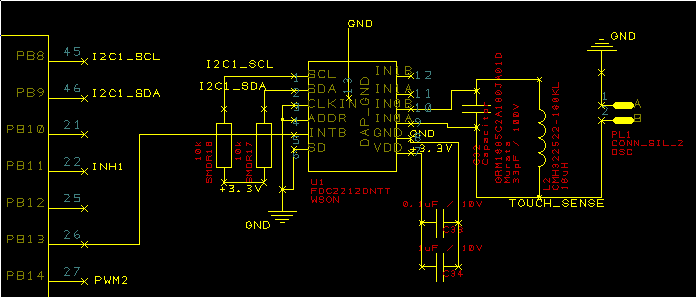

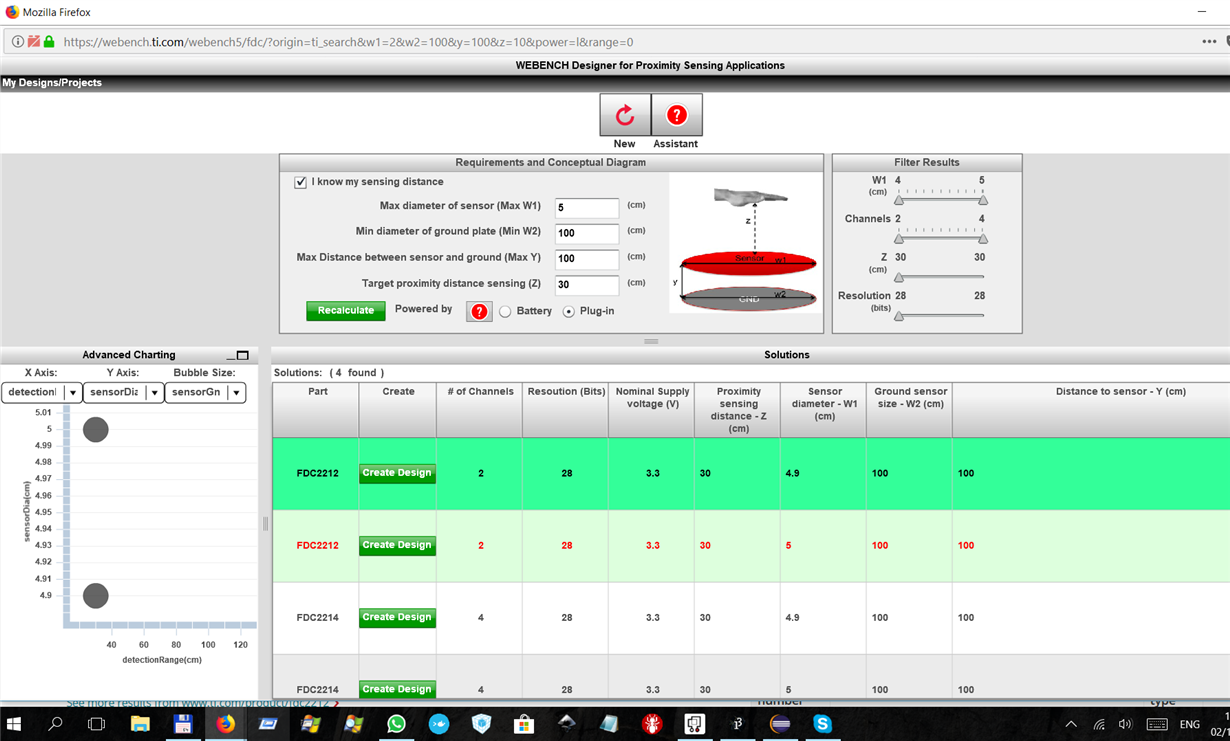

I followed application example on page 42 of fdc2212 manual (http://www.ti.com/lit/gpn/fdc2212).

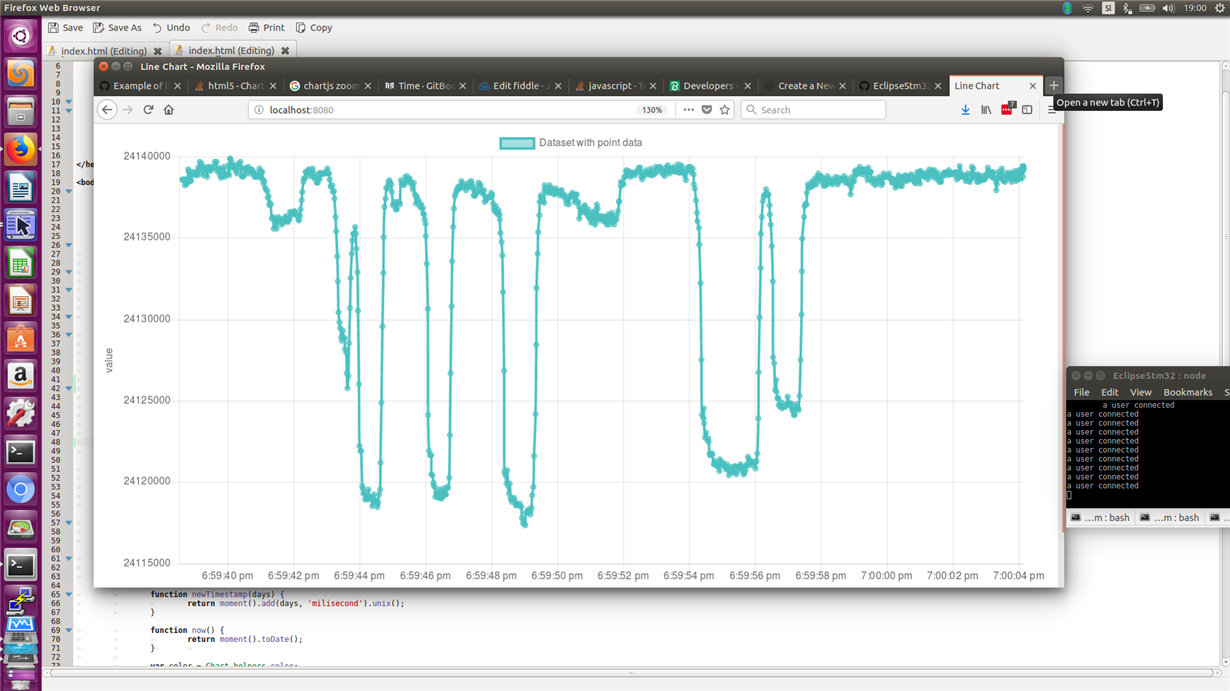

I am interfacing FDC2212 from stm32f303 uC, FDC2212 respond correctly to i2c communication (returns correct MANUFACTURER_ID), but when reading status I get 0 and also all values DATA_CH0 and DATA_LSB_CH0 are always 0.

What I am doing wrong?

Code is available at:

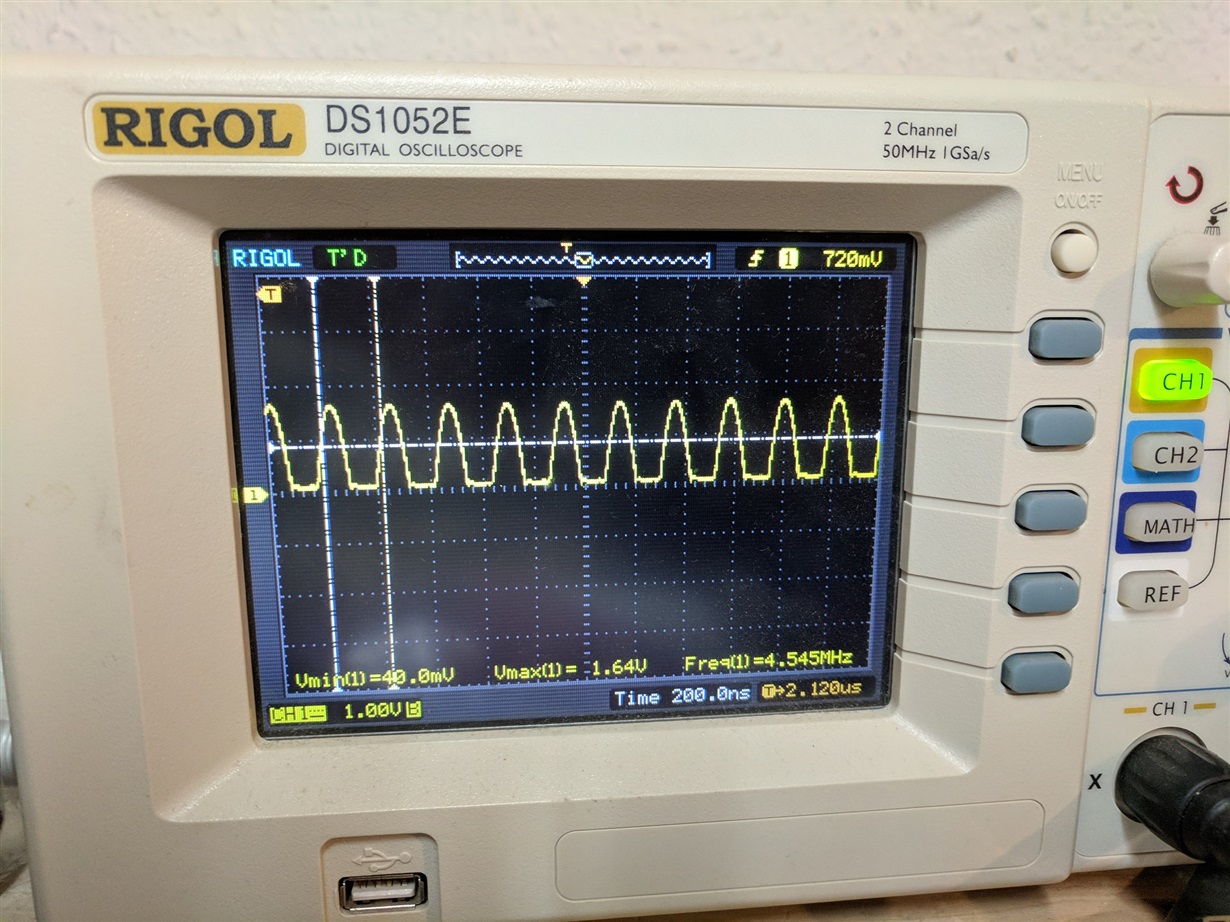

On osciloscope I clearly see signal on 18uH inductor. Picture of scope attached.