Other Parts Discussed in Thread: FDC2214, FDC1004, TIDA-00317

Hello,

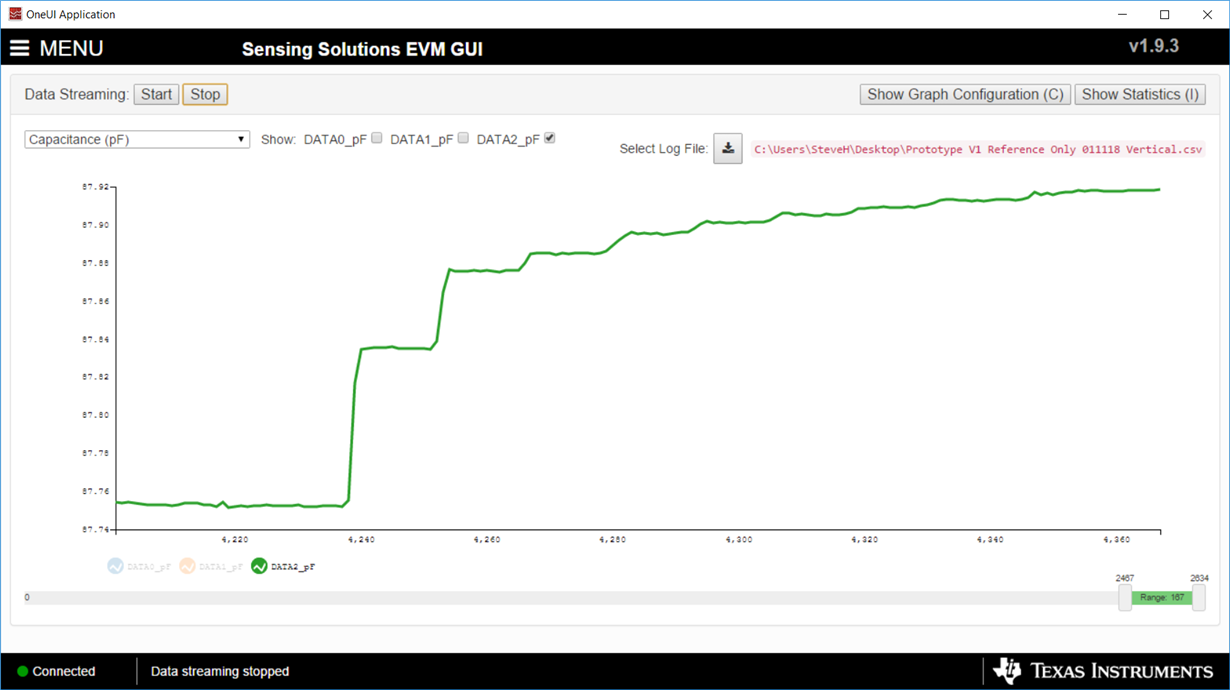

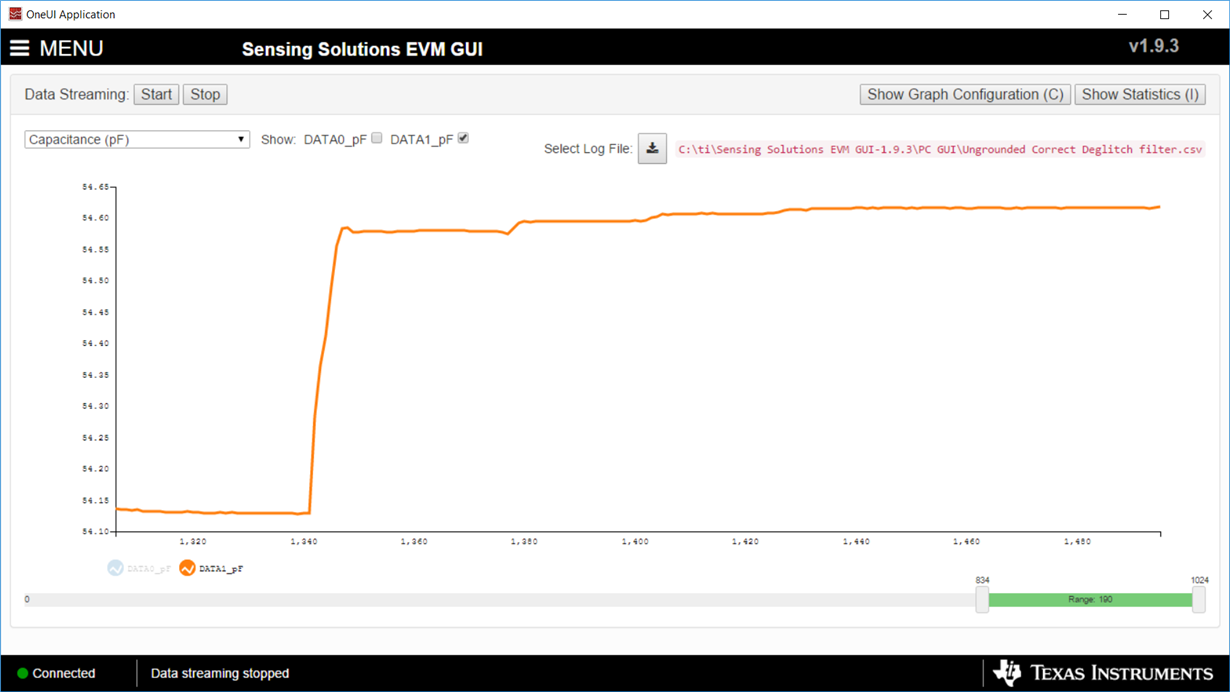

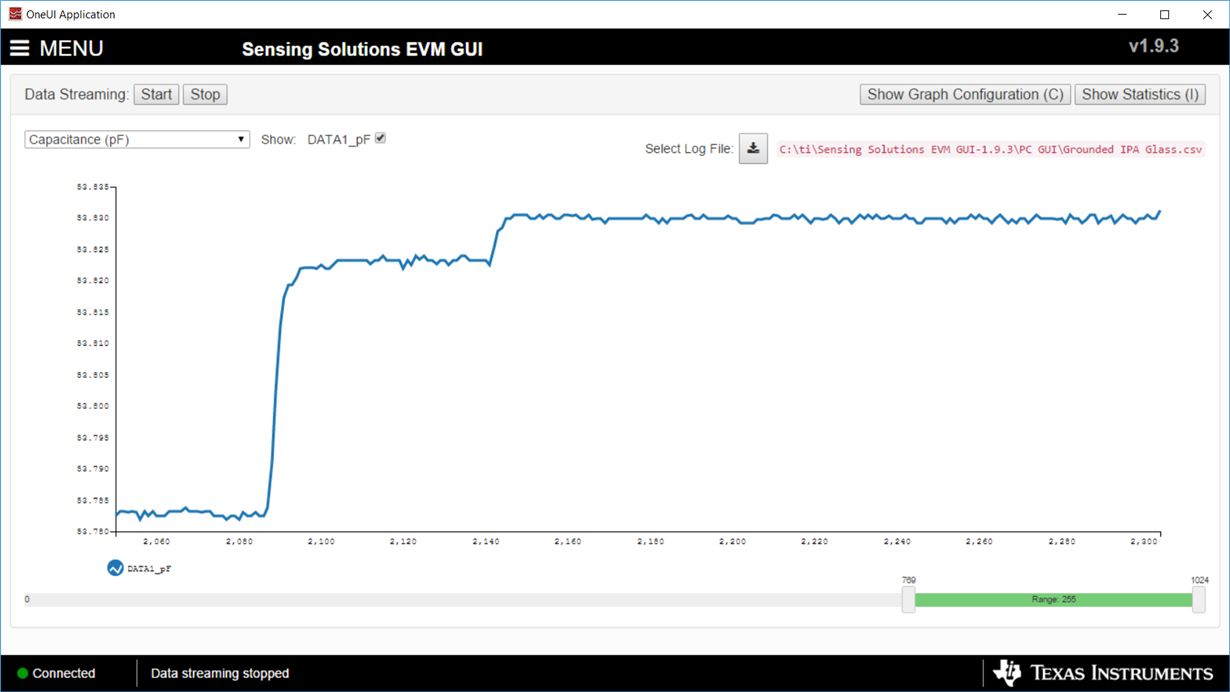

I'm looking to develop a capacitive liquid level sensor for measuring water with various amounts of salt and possible other ingredients. I chose the FDC2214 over the FDC1004 due to the LC-resonator architecture, and it's ability to sample in the MHz range, which should allow measurements of conductive liquids. I've done early testing with distilled water, trying to develop a reference sensor at the bottom of the container to monitor the permittivity of the liquid, since it may change in composition over time. The results of the testing are showed below:

The sensor consists of two parallel plates, about 20 mm x 10 mm each, on a two-sided pcb, with the back side grounded. The sensor is facing the container, and the area in front of the sensor is filled with water after the second step (increase in capacitance). Each step increase in capacitance represents depositing a consistent volume of liquid into the container. So beyond this point, changes in the capacitance of the sensor should be correlated to changes in the permittivity, to adjust the level equation as seen in TIDU736A.

However, as you can see, the capacitance continues to increase as the total volume of liquid in the container increases. I'm confused as to why this is happening, since the FDC2214 is supposed to be better-equipped to handle conductive liquids. Also, in TIDU736A, the FDC1004 is used to test water, which is the same liquid I used for our testing (distilled water). Yet, the Reference Liquid (RL) sensor value does not change according to the results in the TI application note despite higher levels of water.

Please let me know if anyone can offer any assistance in trying to figure out what the problem is, this is the third capacitance sensor we have attempted to use. Also, we're using the FDC2214 evaluation board, and the sensor frequency for the channel used was 4.005 - 4.001 MHz