Other Parts Discussed in Thread: FDC1004

Hi

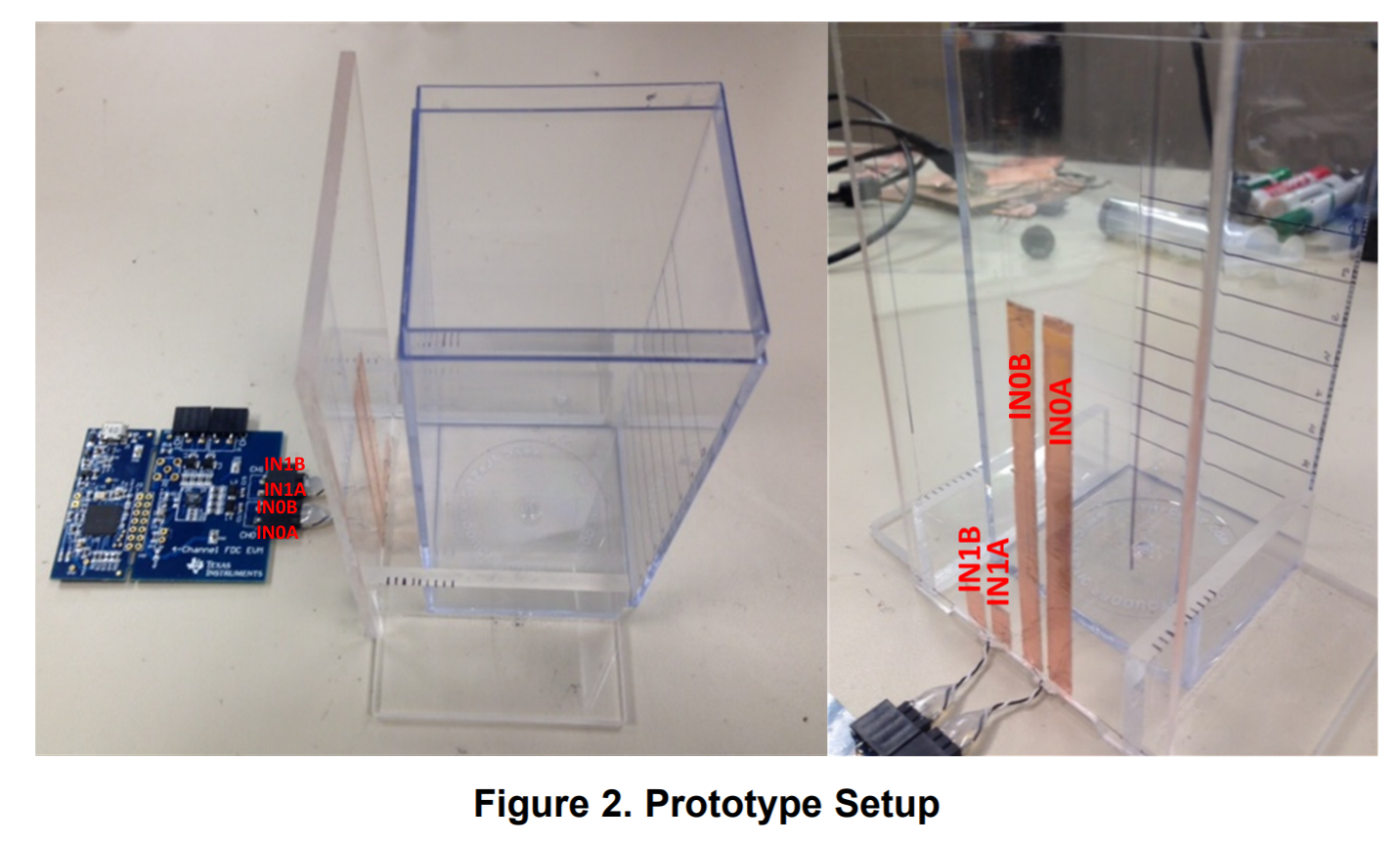

Our customer are considering FDCxxxx device and refers the following application note which is SNOA935A.

http://www.tij.co.jp/jp/lit/an/snoa935a/snoa935a.pdf

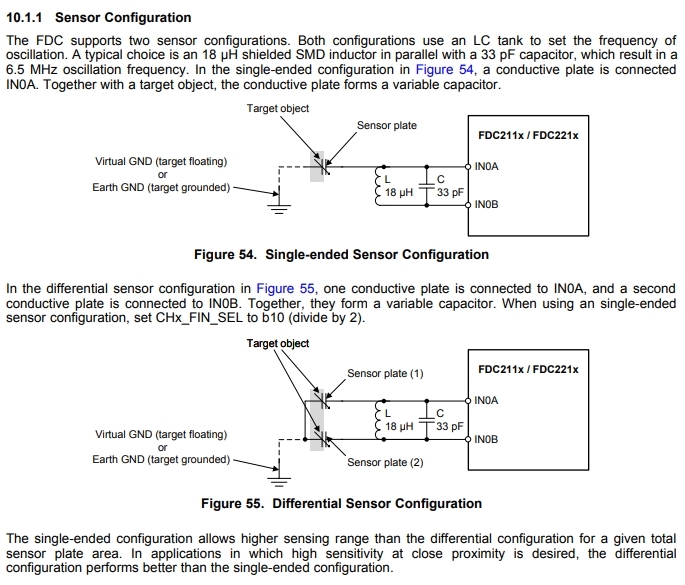

In this case there are two sensors which is level sensor and reference sensor. Which does the configuration use at this case? (single-end? or differential?)

On the datasheet, there is mentioned an advantages of single and differential.

Which do you recommend, the single-end or differential at this application?

On the other hand, how should we shield the reference sensor at differential configuration if we use the refernce sensor?

(I think the common-mode noise might be ok but the different noise at the each sensor are affected.)

Regards,

Koji Hamamoto