Hello Team,

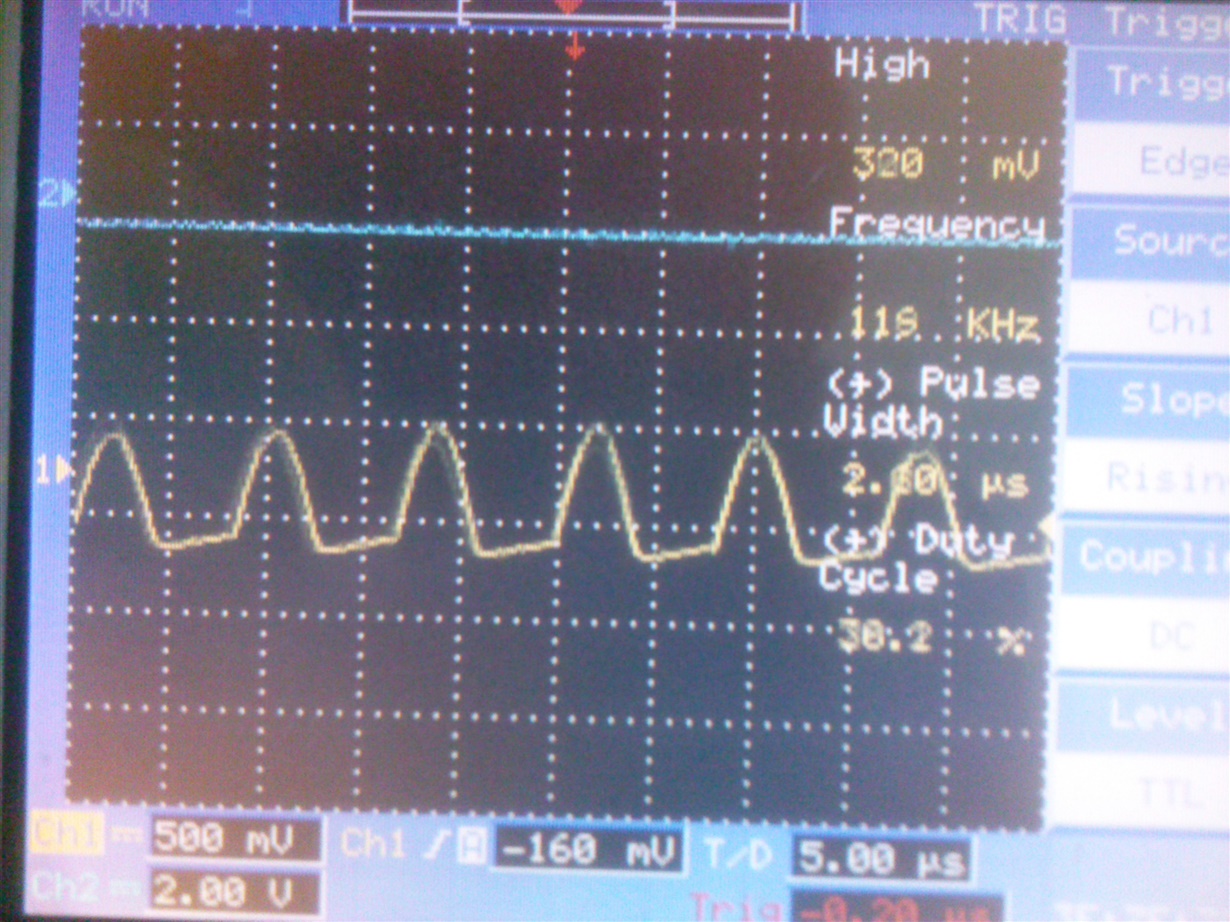

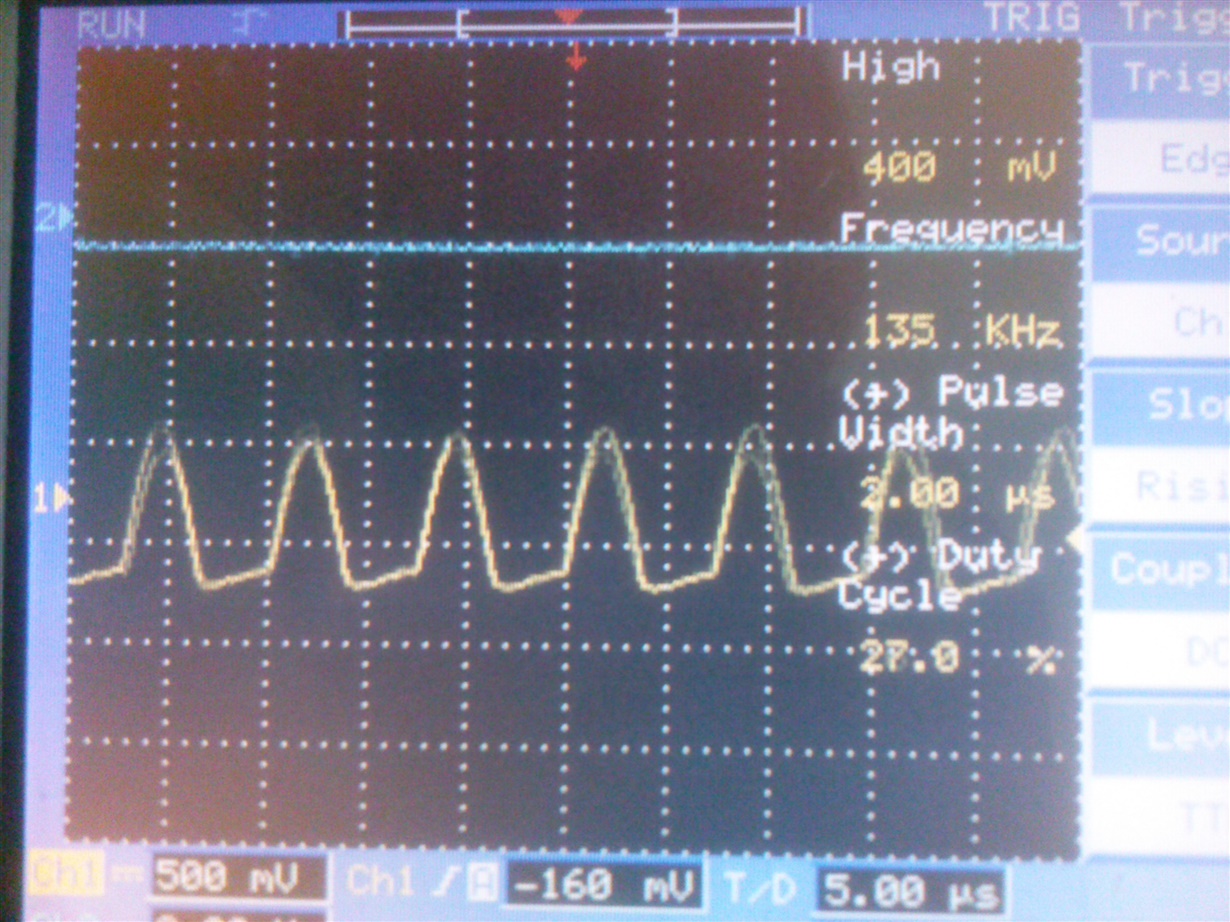

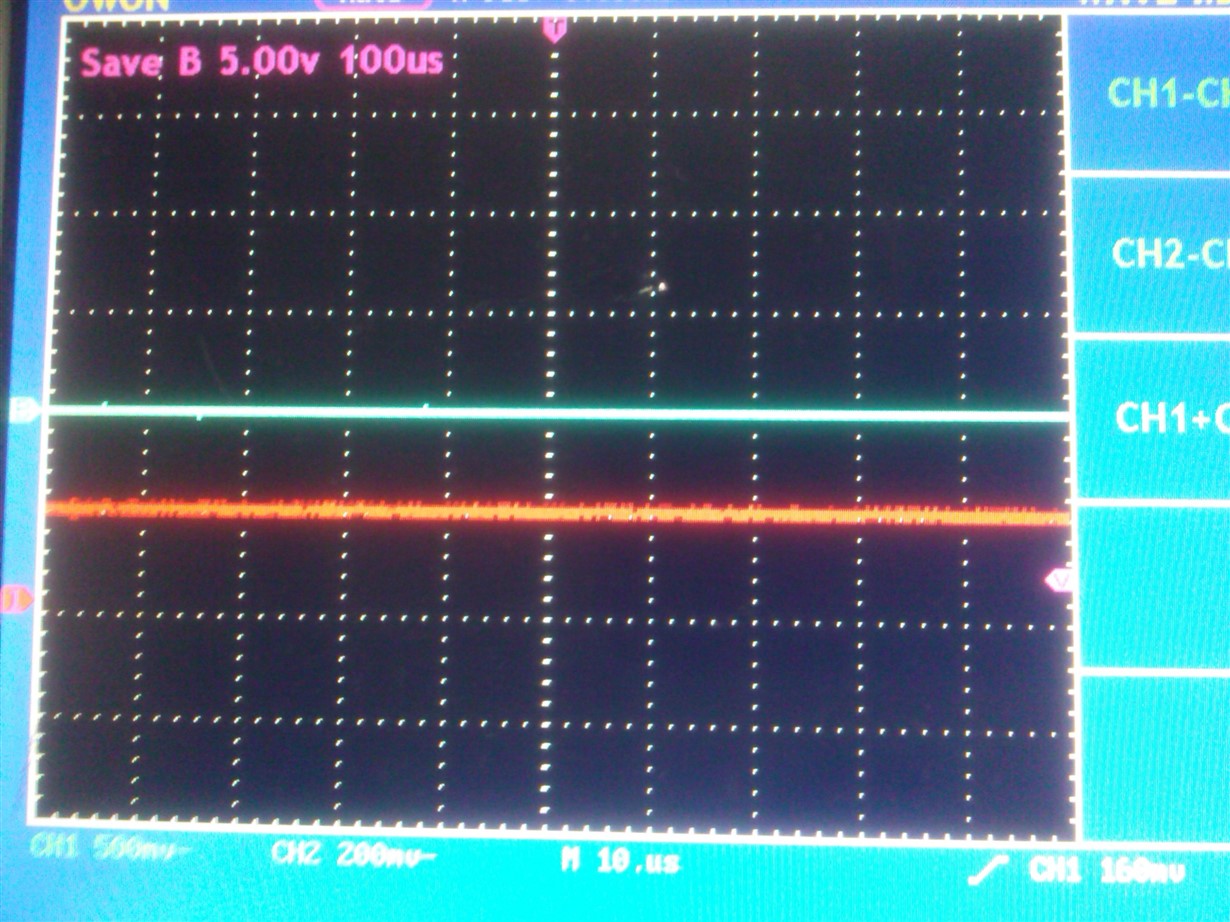

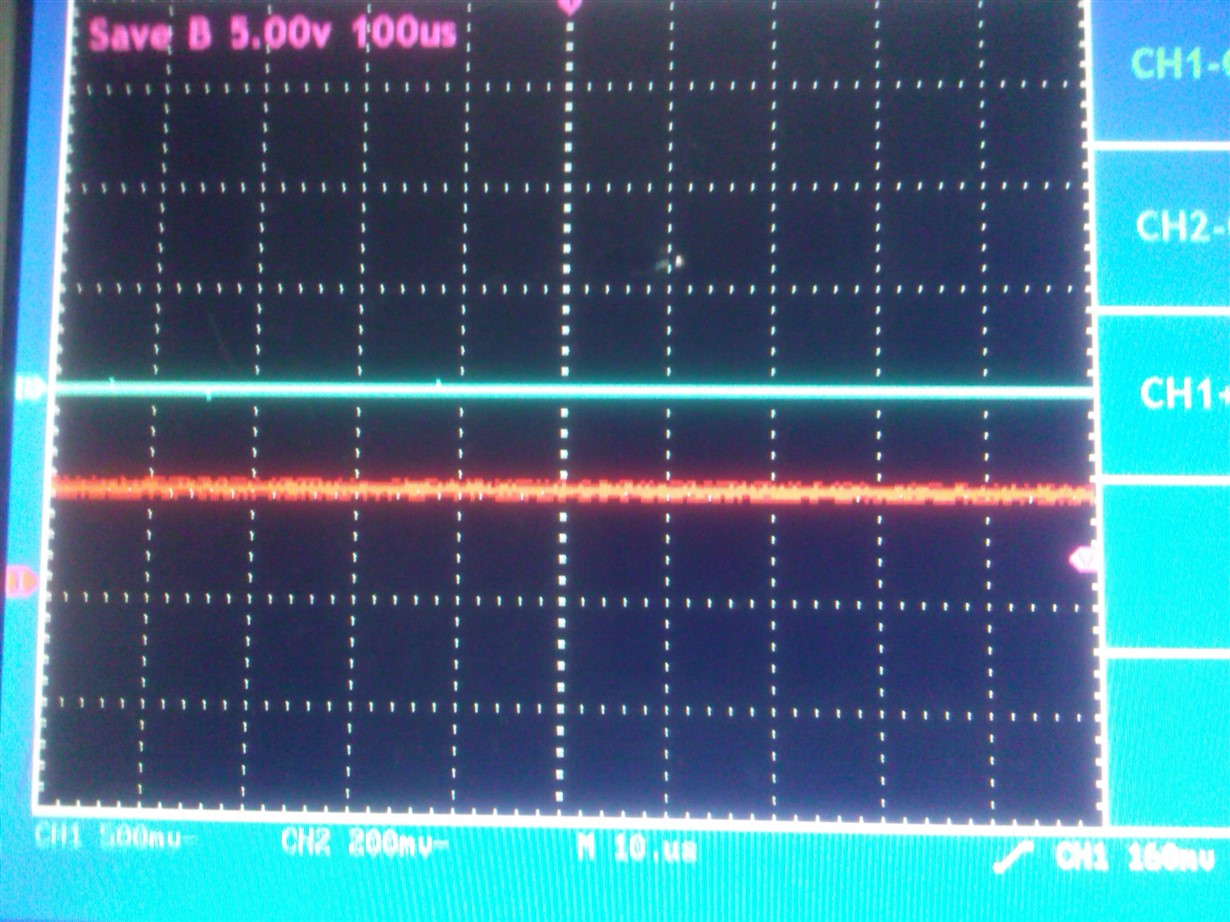

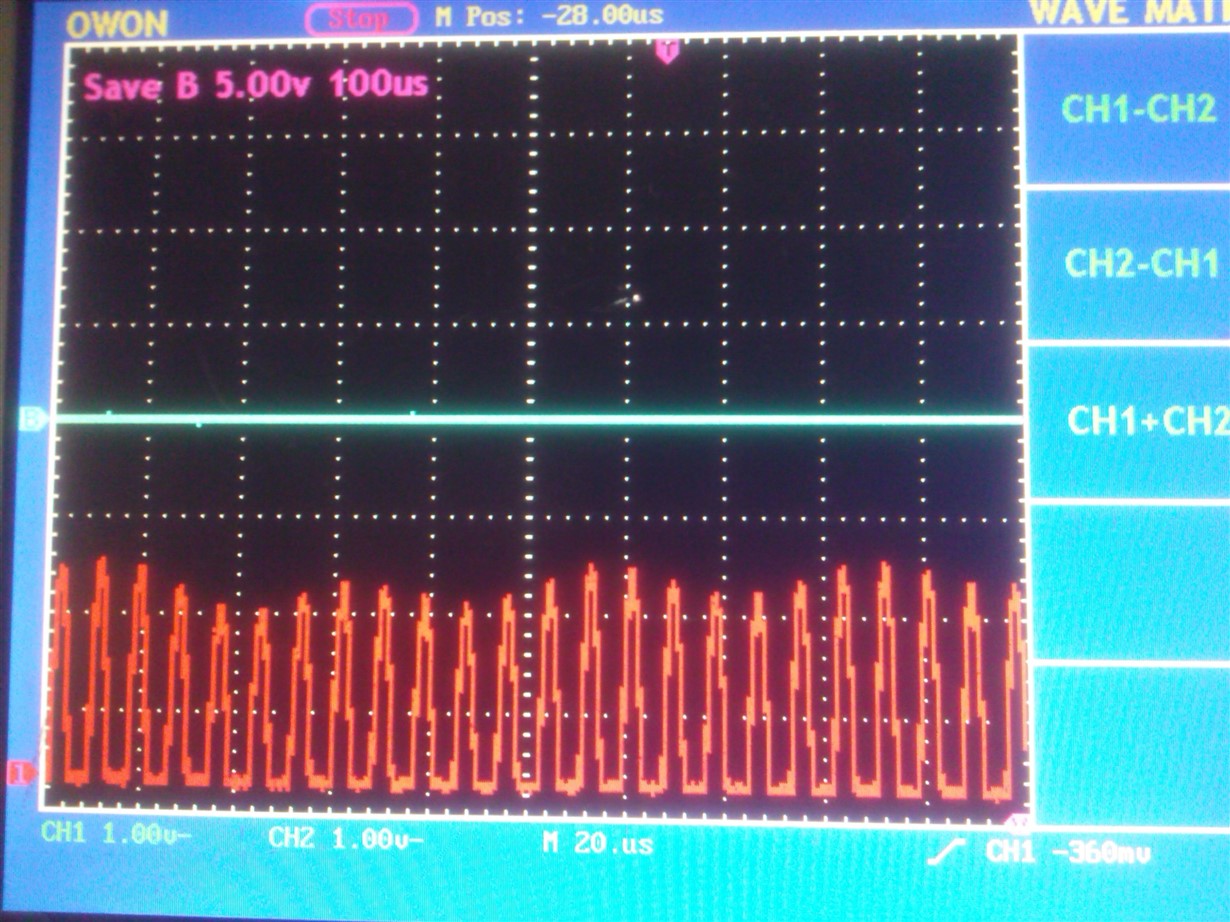

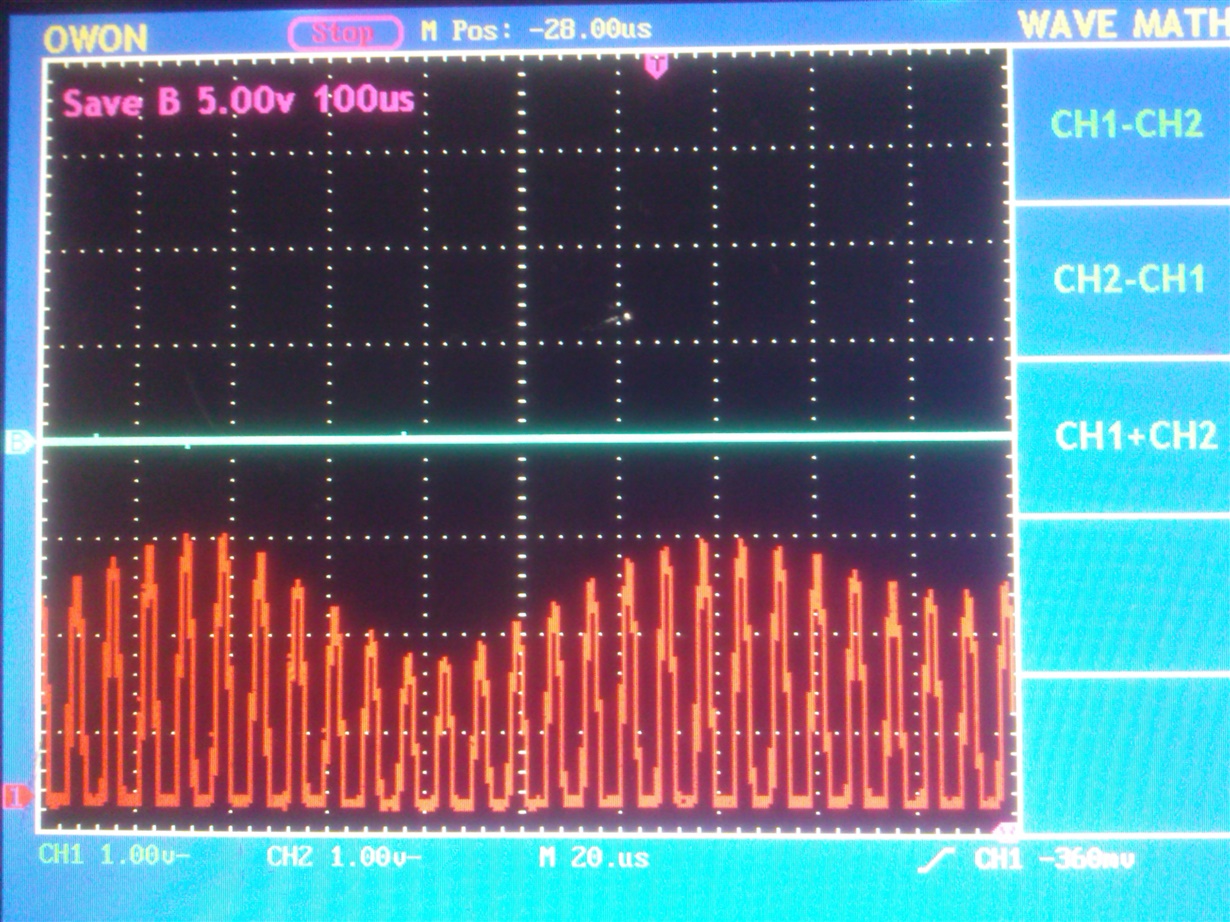

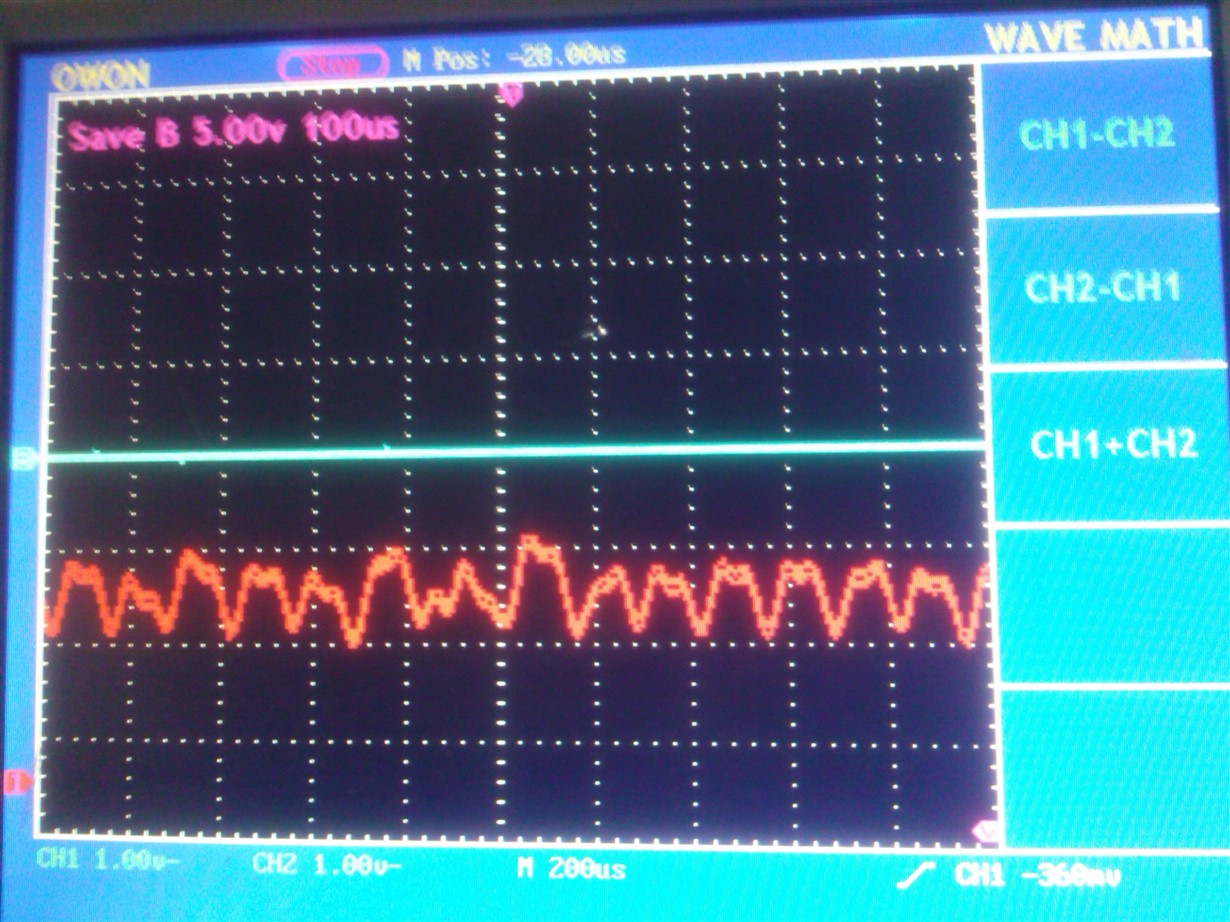

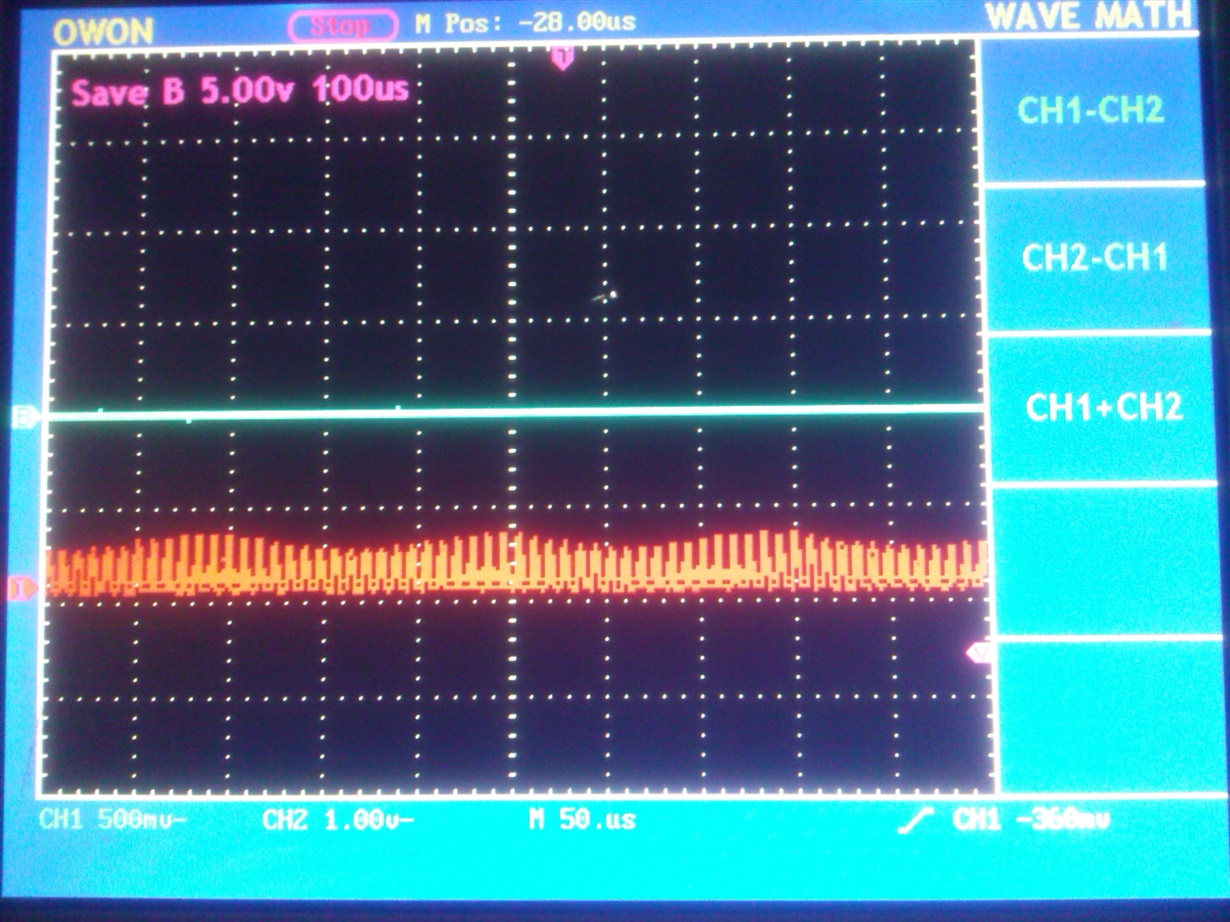

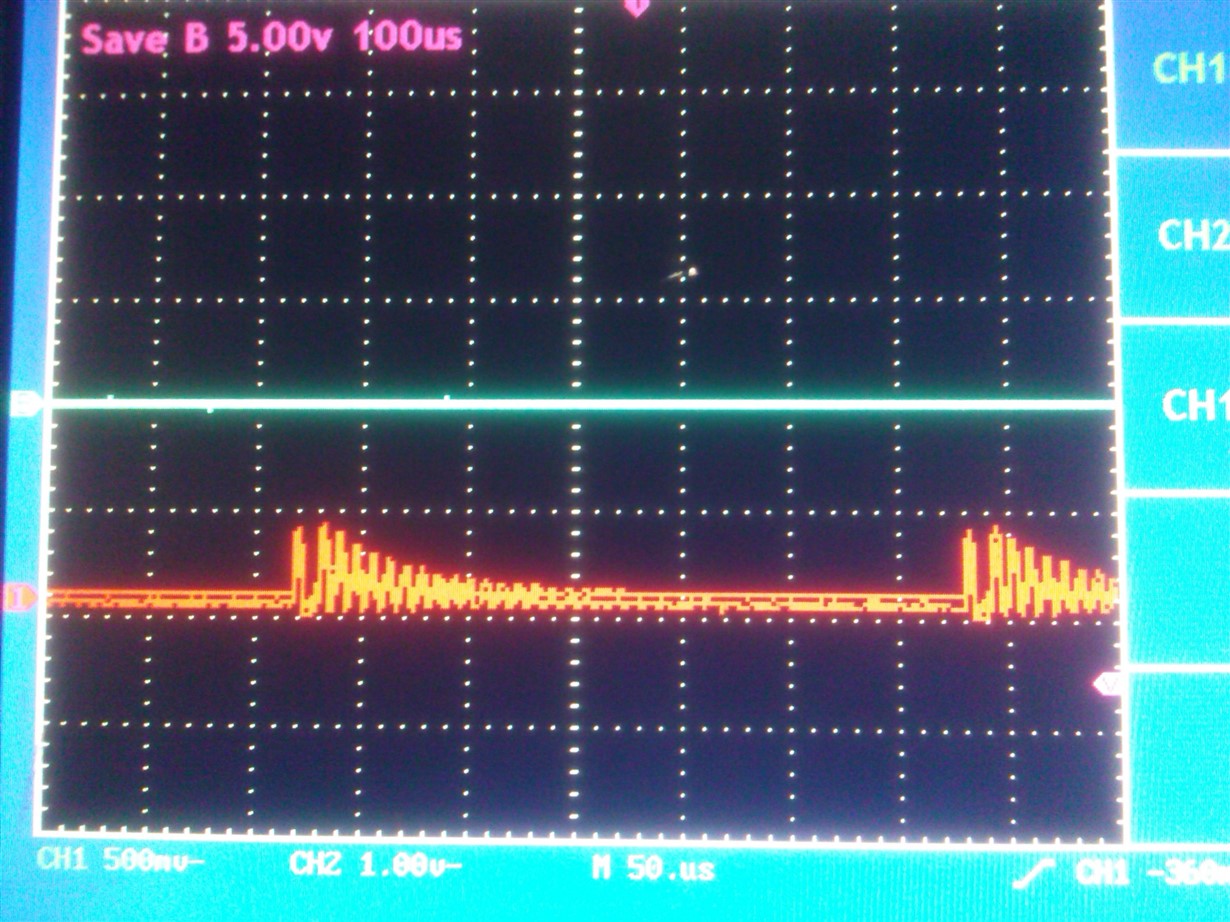

We conducted an experiment with a COIL and Rp min/max configuration, so that we can overflow the proximity data. While reading the value of "128" there are single cases when the values goes from 128 to 0 and then immediately back to 128.

What could be the reason for this behavior ?

Regards,

Varban