Hello,

I´ve got a question about LDC1614.

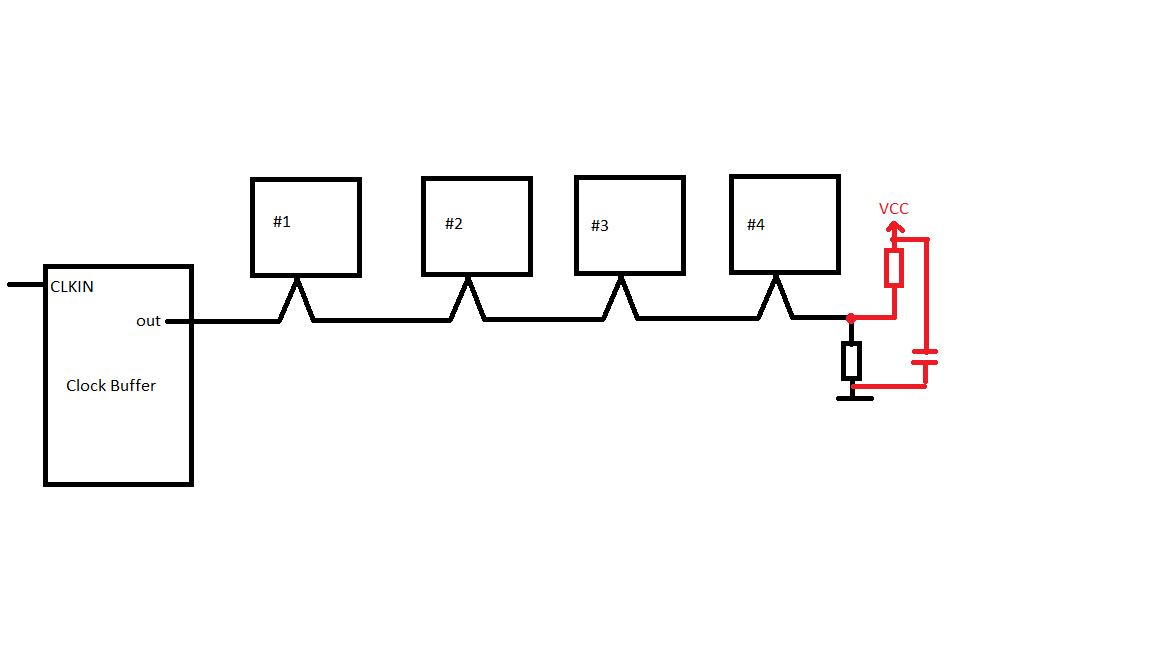

I want to use a oscillator to run multiple LDC1614, so I thought about using a 3.3 V HCMOS oscillator. For this I need a buffer because of output load of each chip. How much is the output load of each LDC1614 chip?

Thanks for your help!

Best Regards

Tim