Hi,

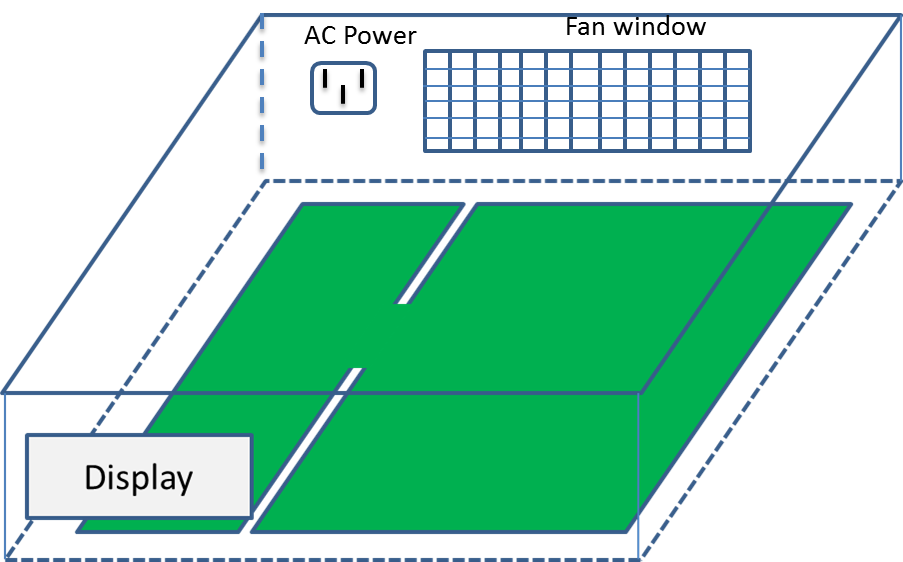

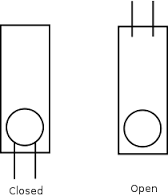

One of my customers has designed a Pizza box sized switch. This is a standalone box and does not plug into any backplane. The power to this is through AC power chord. They need to detect the orientation of this box. It essentially has only 2 orientations- 0 or 180 when flipped.

They need to sense this orientation in order to correct the front display according to the orientation.

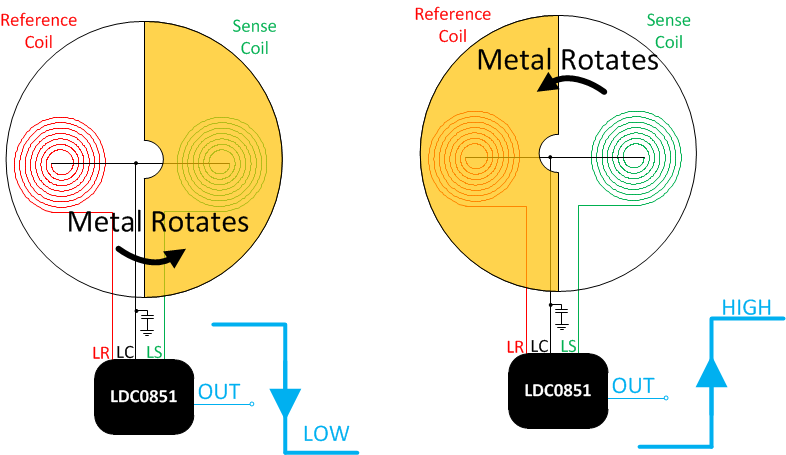

Can we use the LDC/FDC here in order to achieve this? Or any sensing solution form TI?