Other Parts Discussed in Thread: LDCCOILEVM, LDCTOUCHCOMCOILEVM, LDC2114EVM

Hello Team,

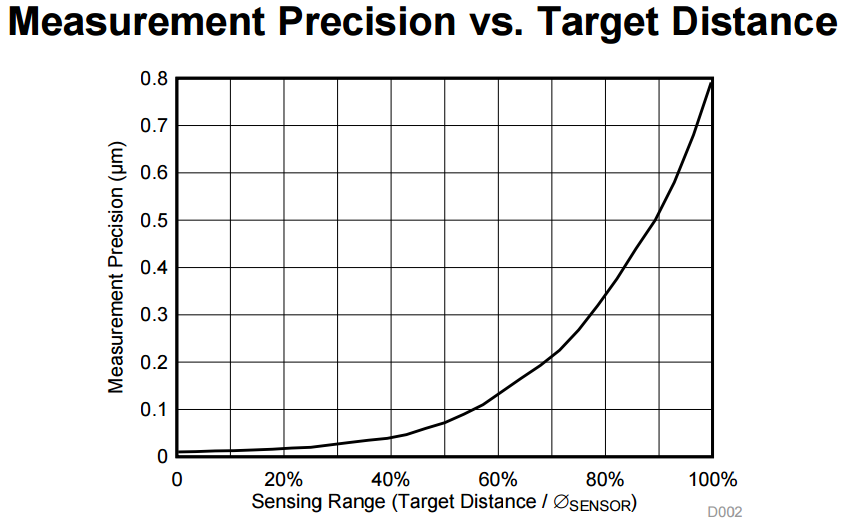

In webench coil design, it shows distance resolution.

Below first row LDC coiil shows distance resolution of 0.0207um.

May I know if 0.0207um is the tested performance that LDC1612 system can achieve?

Since there is no LDC1612 noise floor specified in datasheet, I am not sure if the 0.0207um includes LDC1612 noise floor.

Thank you.

Regards,

Ting